ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

JUKI Smart Solutions Foster Automation, Efficiency

With the keywords of JUKI Smart Solutions ~ Automation and Efficiency – Transformation of Production Process with Customers – JUKI proposes at productronica 2021 two process innovations to achieve automation and efficiency enhancement that lead to the transformation of production process together with customers.

SMT Process Efficiency Innovation

The RX-8 high-speed compact modular mounter, which highlights tact performance of 100,000cph, features compact design and high-speed mounting at 100,000cph, and achieves the highest area productivity in its class. In particular, in the mounting of chip components and light-emitting diodes (LEDs), it achieves effective tact performance of 60,000cph. It is an optimum model, not only for ultrasmall chip components and small ICs, but also for the production of products that use LED edge lights and require high-density mounting and high accuracy (Photo 1).

JUKI proposes not only the machine itself, but also the improvements of productivity and quality of the entire SMT line, and linkage among machines. To achieve this, it combined RX-8, RS-1R all-in-one mounter, and RV Series high-performance automated optical inspection system.

In the components supply process, linkage among Incoming Material Station, which enables immediate response to urgent acceptance of components, ISM Series storage system, and X-ray reel counter, improves the efficiency of various works relating to the acceptance and delivery of components. This includes registration of receiving components, take-out of component at an appropriate timing, and cumbersome inventory work, thereby achieving dramatic improvement of productivity (Photo 2).

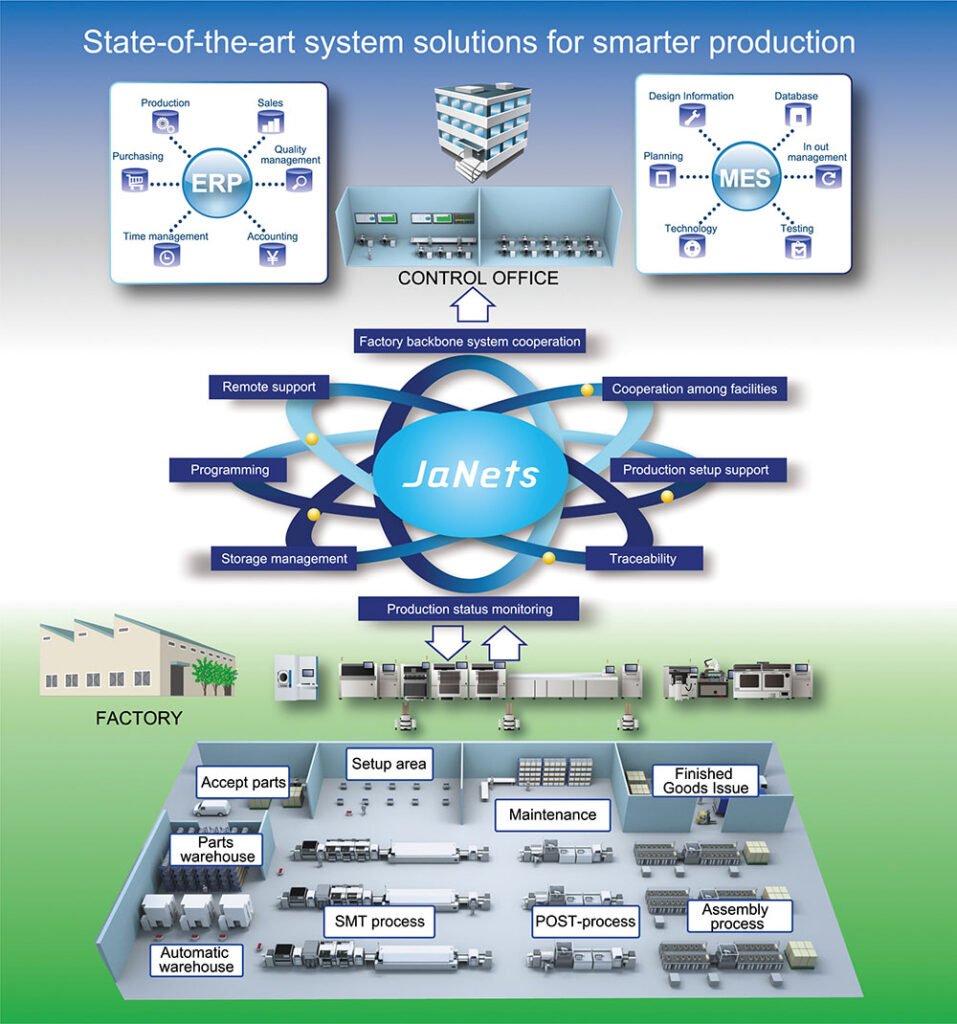

Moreover, integration with JaNets system software, which improves the efficiency of the entire SMT line, enables the linkage of various systems, including the bad mark propagation function between the mounter and inspection machine, residual number management function in the component management process, and visualization of production progress and equipment operation conditions. JUKI proposes innovative transformation of the production process that will lead customers’ plants into efficient production plants (Photo 3).

JUKI has in its portfolio a series of systems ranging from warehousing system, surface mounting system, inspection system, to advanced production management system. The company proposes the transformation of production process by achieving dramatic improvement of productivity through heightening efficiency of the entire SMT process and making it smart.

Post-Process Automatic Innovation

As a leading company in the automation of post-process production of printed circuit boards, including the insertion of components and assembly work, JUKI has been working to solve problems together with customers by offering the JM Series, which has earned high reliability. This time, the JM-50 new multitask platform has been added to its lineup. It inherits the insertion technology of the JM Series and exhibits excellent productivity in high-mix, low-volume production. JUKI has developed a mini chuck nozzle, which supports components with different sizes using a single nozzle. It significantly reduces nozzle changeover work for different components, thus achieving dramatic improvement of insertion tact performance. In addition, the newly developed MVF general-purpose bulk feeder enables smooth supply of randomly stacked parts, whereby it meets a wide variety of components delivered in various shapes. By significantly improving set-up performance, it has improved productivity in high-mix, low-volume production.

The MR-01 innovative robot system is a robot system platform wherein the upper and lower robots can simultaneously perform different tasks, such as “insertion of large connector components and screw fastening task,” and “substrate splitting and dust collection tasks” that require human intervention. Installing this platform achieves transformation of the production process and realizes high area productivity and improvement of return on investment (ROI).

JUKI intends to continue automating various assembly tasks in accordance with customers’ requirements to further expand customers’ domain of automation.

In process innovation to automate post process, JUKI supports the resolution of challenges and automation of the post process leveraging the JM Series bolstered by the addition of JM-50 robot technology, and support capability (Photo 4).

JUKI will continue expanding solutions to solve problems and transform the production process together with customers by fully utilizing its reliable and proven technological expertise and support capabilities.