ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Nidec to Offer Better Productivity With Latest Tool

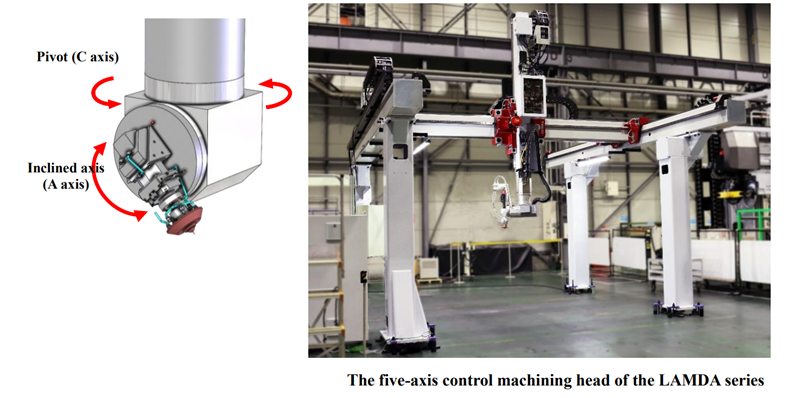

Nidec Machine Tool Corporation has developed a five-axis control machining head. Specifically, they will complement the company’s LAMDA series, which are powder DED type*1 metal 3D printers. Compared with conventional five-axis modeling machines with fixed head and rotating work-pieces, the new head is free from restrictions based on the metal 3D printer’s devices. Moreover, they can perform additive fabrication of large, complex-shaped components and adjustable surfaces. Furthermore, they come with the one-of-a-kind local shield nozzle*2 and monitoring feedback*3 functions. Thus, the LAMDA series guarantees high-quality and stable machining.

Going forward, the Company aims to expand the head’s applications to, among others, surface modification and repair molding. Specifically, in aerospace and space industry-related components, the molds of automobile bodies, and large industrial blades. Thus, contributing to improving those products’ quality and reducing their costs.

Easy Machining of Complex Shapes, Surfaces

This newly developed powder DED-type, five-axis control machining head can perform additive fabrication at an arbitrary angle. Most importantly, even without rotating the table for the work-piece even when the workpiece is large. Also, moving and rotating the table is difficult.

With two rotating axes incorporated (i.e., with both the inclined axis (A axis) and the pivot (C axis) installed inside the head) in them, the LAMDA series models has a wide range of the rotational axis’ movement (A axis: -90˚ to +90˚, C axis: -180˚ to +180˚) to secure a high degree of freedom.

In addition, the LAMDA series models enjoy a compact head and driving section to secure accessibility between the nozzle’s tip and the workpiece. Also, it features high speed and responsiveness, while maintaining the variable function of the models’ laser illumination diameters. Therefore, enabling easy machining of complex shapes and adjustable surfaces.

Since releasing LAMDA200 in 2019, the Company has been developing and realizing the following cutting-edge technologies in high-speed processing, precision assurance, etc.:

- Creating the second generation of models, with their shield ranges significantly widened from those of the first local shield nozzle;

- Launching LAMDA500, a five-axis molding machine with a rotating work table;

- Developing LAMDA2000, a model with a gantry-type, direct-action mechanism capable pf handling large workpieces; and

- Adding an AI-based (artificial intelligence-based) lamination layer status checking function.

Nidec Machine Tool are showcasing these new technologies at Japan International Machine Tool Fair 2024 (JIMTOF2024) in Tokyo until November 10.

Notes

*1. DED: Short for directed energy deposition, this additive fabrication process utilizes a concentration of thermal energy to melt materials.

*2. Local shield: A function to convert a molten pool’s surrounding area into an inert gas atmosphere during a shaping (molding) process. This function enables, without the use of an argon chamber, the shaping (molding) of titanium, aluminum, and other anti-oxidation materials in an atmospheric environment.

*3. Monitoring feedback function: This function utilizes the results of the monitoring of shaping (molding) conditions using a camera installed coaxially with laser, to control laser output and other shaping (molding) conditions, and stabilize metal meltdown and solidification.

06 November 2024