ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Sony Semiconductor’s New Sensor to Surge Vehicle LiDAR

Sony Semiconductor Solutions Corporation (SSS) has announced the upcoming release of the IMX479 stacked, direct Time of Flight (dToF) SPAD depth sensor for automotive LiDAR systems. Thus, delivering both high-resolution and high-speed performance.

The new sensor product employs a dToF pixel unit composed of 3×3 (horizontal × vertical) SPAD pixels as a minimum element to enhance measurement accuracy using a line scan methodology. In addition, SSSs proprietary device structure enables a frame rate of up to 20 fps*1, which is the fastest for such a high-resolution SPAD depth sensor having 520 dToF pixels.*2

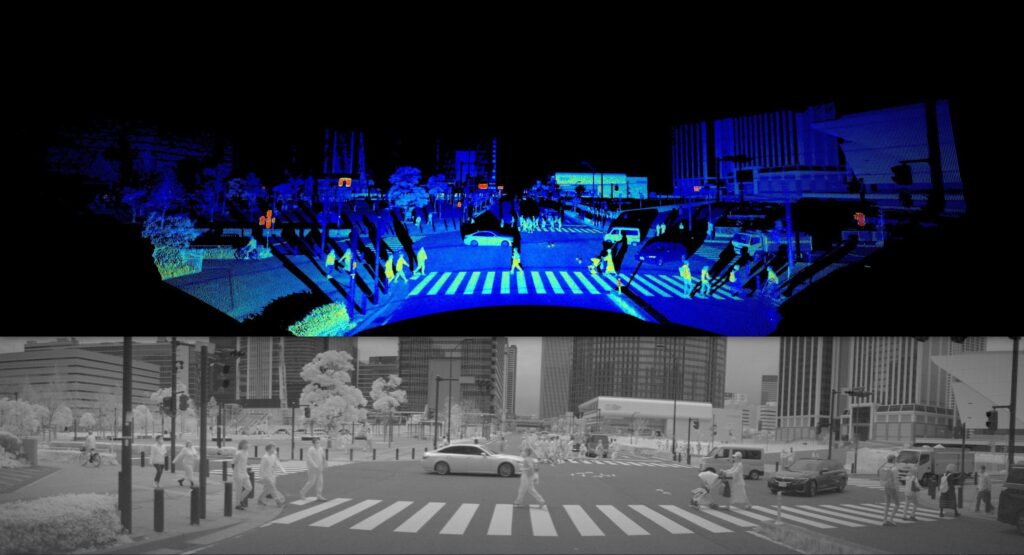

The new product enables the high-resolution and high-speed distance measuring performance demanded for an automotive LiDAR required in advanced driver assistance systems (ADAS) and automated driving (AD), contributing to safer and more reliable future mobility.

Crucial Technology

LiDAR technology is crucial for the high-precision detection and recognition of road conditions and the position and shape of the objects, such as vehicles, pedestrians. There is a growing demand for further technical advancements and developments progress in LiDAR toward Level 3 automated driving, which allows for autonomous control.

SPAD depth sensors use the dToF measurement method, one of the LiDAR ranging methods, that measures the distance to an object by detecting the time of flight (time difference) of light emitted from a source until it returns to the sensor after being reflected by the object.

The new sensor harnesses SSS’s proprietary technologies acquired in the development of CMOS image sensors, including the back-side illuminated, stacked structure and Cu-Cu (copper-copper) connections.*4 By integrating the newly developed distance measurement circuits and dToF pixels on a single chip, the new product has achieved a high-speed frame rate of up to 20 fps while delivering a high resolution of 520 dToF pixels with a small pixel size of 10 μm square.

Main Features

- Up to 20 fps frame rate, the fastest for a 520 dToF pixel SPAD depth sensor*2

This product consists of a pixel chip (top) with back-illuminated dToF pixels and a logic chip equipped with newly developed distance measurement circuits (bottom) using a Cu-Cu connection on a single chip. This design enables a small pixel size of 10 μm square, achieving high resolution of 520 dToF pixels. The new distance measurement circuits handle multiple processes in parallel for even better high-speed processing.

These technologies achieve a frame rate of up to 20 fps, the fastest for a 520 dToF pixel SPAD depth sensor.*1 They also deliver capabilities equivalent to 0.05 degrees vertical angular resolution, improving the vertical detection accuracy by 2.7 times that of conventional products.*5 These elements allow detection of three-dimensional objects that are vital to automotive LiDAR, including objects as high as 25 cm(such as a tire or other objects in the road) at a distance of 250 m. - Excellent distance resolution of 5 cm intervals

The proprietary circuits SSS developed to enhance the distance resolution of this product individually processes each SPAD pixel data and calculates the distance. Doing so successfully improved the LiDAR distance resolution to 5 cm intervals. - High, 37% photon detection efficiency enabling detection of objects up to a distance of 300 m

This product features an uneven texture on both the incident plane and the bottom of the pixels, along with an optimized on-chip lens shape. Incident light is diffracted to enhance the absorption rate to achieve a high, 37% photon detection efficiency for the 940 nm wavelength, which is commonly used on automotive LiDAR laser light sources. It allows the system to detect and recognize objects with high precision up to 300 m away even in bright light conditions where the background light is at 100,000 lux or higher.

Mechanical scan LiDAR for evaluating the product

SSS has developed a mechanical scanning*6 LiDAR unit equipped with this new sensor for product evaluation, which will be provided to customers and partners. This will contribute to customer and partner LiDAR development and product evaluation initiatives.

Notes:

*1 The frame rate may vary depending on horizontal FoV (Field of View) and its resolution.

*2 According to SSS research (as of announcement on Jun 10, 2025)

*3 Differs depending on the handling quantity.

*4 A technology used when a pixel chip (top) is stacked with a logic chip (bottom), to achieve electrical continuity by connecting the Cu (copper) pads to each other. This increases the flexibility in the design, improves productivity, and enables a smaller size and higher performance compared with Through-Silicon Vias (TSV), where the upper and lower chips are connected via electrodes around the circumference of the pixel area

*5 Compared with SSS’ IMX459 1/2.9-type 100,000-effective pixel SPAD depth sensor.

*6 A method in which a rotating mirror reflects the beam from a fixed laser light source for wide area horizontal scanning.