ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Dobot Unveils New CRA Series Cobots at Automate Show

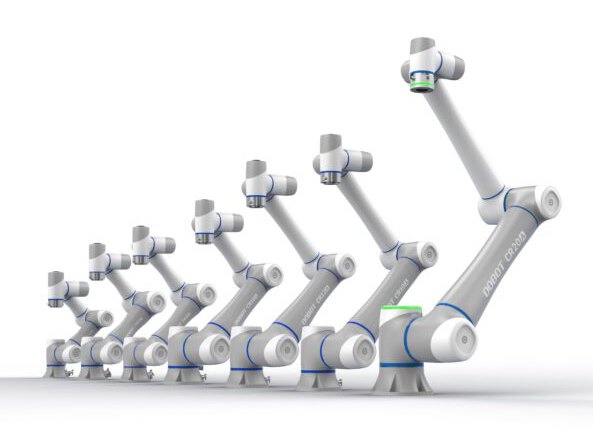

Brand new CRA Series collaborative robots (cobots) and the CRV500 Smart Camera from Dobot were officially launched at the Automate Show. The new cobots incorporate high-performance harmonic drive reducers and electromagnetic brakes, alongside updated software with redesigned user interface. Compared to its predecessor, the CRA Series has noticeable performance boost, and is more efficient, safer and easier to use. Moreover, the CRV500 Smart Camera leverages Dobot’s self-developed 2.5D spatial compensation technology. This allows equipped robots to grab tilted or inclined objects with higher precision, opening doors to a variety of vision-based automation scenarios.

With the rapid expansion of cobot application scenarios, the market today seeks high-performance robots. Dobot has always been exploring the optimal human-machine collaborative solution. In fact, it has built more than 20 robot models to target different use cases and industries. The high-performance CRA Series aims to satisfy the most demanding users to accelerate their transition to automated solutions to increase their production gains.

CRA Series: New Architecture for Better Performance

Higher efficiency

The self-developed highly integrated joints with high-performance harmonic drive reducers improve cycle time by 25%.

Greater accuracy

An optimized precision control algorithm greatly reduces vibrations. Specifically, it exhibits up to ±0.02mm repeatability and 0.2 to 0.4mm trajectory accuracy during complex motion.

Much safer

The electromagnetic brakes auto-engage in 18msec at power outage to restrict robotic arm falls less than 1mm, thus effectively preventing end tool from dropping. Also, the CRA Series has built-in virtual boundaries, real-time payload detection, and other safety features to ensure the safety of nearby workers.

Easier to use

The brand-new operating software is more user-friendly to operate. It supports graphical programming, scripting and drag-to-teach for trajectory replay. Also, it is multi-platform and works with personal computers, tablets and smartphones and more.

More reliable

The control box is 25% smaller with optional IP54 protection. It can withstand harsh environments to help lower maintenance costs.

Moreover, the CRA Series supports Modbus, Ethernet/IP and Profinet communication, connecting with PLC and other automation systems seamlessly. With 24 I/O ports available and PNP/NPN switching, it is easier to carry out expansion.

CRV 500 Smart Camera: Accurate Grabbing with Self-developed Algorithm

At the exhibition, Dobot also launched another new product, the CRV500 smart camera. With Dobot’s self-developed 2.5D spatial compensation technology, it can be used with the CRA and CR Series collaborative robots to enable accurate identification of objects’ horizontal angle and inclination for accurate grabbing.

Specifically, the CRA Series released this time has seven robot models with 3kg, 5kg, 7kg, 10kg, 12kg, 16kg and 20kg payloads. Also, it has a working radius from 620 to 1,700mm, covering various industries including consumer electronics, semiconductor, automotive, renewable energy, metal processing, logistics, healthcare, retail and more. It is also capable of dozens of high-precision applications, such as pick and place, sorting, screwdriving, inspection, gluing, welding, transportation, polishing, and palletizing, covering high payloads and big areas scenarios.

Dobot has developed specialized process package software to simplify automation deployment of complex processes including screwdriving, welding and palletizing. Also, with this software, users can quickly set up the automation processes without writing a line of code.

The 3kg, 5kg, and 10kg payload models in the CRA Series are compatible with the DOBOT SafeSkin for safer human-machine collaboration. The SafeSkin is Dobot’s exclusive, self-developed non-contact pre-collision detection solution. It senses obstacles coming within 15cm and stop before colliding, effectively increasing the safety and efficiency of human-machine collaboration.