ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

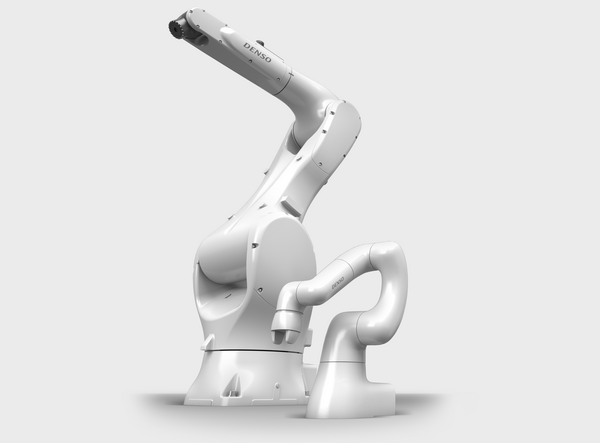

DENSO Highlights Cobot Products at automatica

DENSO Robotics Europe will present product highlights at automatica 2023. The presentation will include the COBOTTA PRO Series, which was presented for the first time in 2022. Also, it will include a real-time synchronization application with SCARA HSR robot. Moreover, it will present the Beckhoff XPLANAR and a DENSO master/slave application with a COBOTTA and VMB. Other highlights include ESD and ATEX protection classes and a robot suitable for aseptic environments.

COBOTTA PRO

The COBOTTA PRO 900 and COBOTTA PRO 1300 create new possibilities in human-robot collaboration. Specifically, they feature outstanding TCP speed of 2100mm/sec and 2500 mm/sec. Also, they feature high repeatability of ±0.03mm and ±0.04mm and a payload of 6kg and 12kg. An optional touch-sensitive soft cover with integrated, highly sensitive sensors allows to further increase the speed during human-robot collaboration.

Real-time Synchronization Application

The harmonious interaction of the HSR SCARA robot and the Beckhoff XPLANAR make it possible to enable real-time synchronization between the robot and the transport mover. In combination with the RC9 controller with integrated TWINCat layers, this allows highly complex applications. Beckhoff’s unique magnetic levitation technology complements conventional transport systems.

DENSO Master/Slave application

With DENSO’s own Master/Slave function, it is possible to move the non-collaborative robot VMB with the Direct Teach function of COBOTTA. Also, the virtual fence of the slave robot is mirrored in the master robot, giving the operator haptic feedback as he approaches the virtual fence.

Protection Classes ESD, ATEX, aseptic environments

Both of its ESD-certified robot series meet the required limits of IEC 61340-5-1:2016 / ANSI/ESD S20.20:2021. This enables safe handling of electronic components, such as PCB assembly, visual inspection, product testing and packaging.

DENSO’s robots have been modified to meet the required limits for Zone 2 & 22 according to the ATEX Product Directive 2014/34/EU and the ATEX Operational Directive 1999/92/EC 21, therefore ensuring explosion protection.

The VS-050S2 meets the stringent requirements of the pharmaceutical and medical industries and is certified accordingly. Requirements include resistance to cleaning agents (35% hydrogen peroxide stream (dry/wet) used in highly sterile environments, resistance to UV radiation, GMP Grade A compliant design, ISO 5 cleanliness level / IP 65/67 protection and Internal wiring complete to 6th axis.