ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Fujitsu-Led Alliance Bats for DX in Manufacturing

Fujitsu-Led Alliance Bats for DX in Manufacturing

Fujitsu Limited, Information Services International-Dentsu, Ltd. (ISID), and DIGITAL PROCESS LTD. (DIPRO) have announced a collaboration in the area of engineering chains. Particularly, the alliance aims to deliver product life cycle management (PLM) systems for customers in the Japanese manufacturing industry.

Background

In April 2022, Fujitsu, ISID, a subsidiary of Dentsu Group Inc., and Dentsu Inc. started a strategic partnership. Accordingly, they aim to realize customer-oriented transformation aligned with three value chains— “engineering chain,” “supply chain” and “demand chain”. Moreover, the companies want to contribute to the continued business growth of client companies and the resolution of environmental and societal issues.

As part of this partnership, Fujitsu and ISID announced the launch of a joint project to provide Siemens Digital Industries Software’s (1) product life cycle management (PLM) system “Teamcenter,”. Moreover, will work toward achieving digital transformation (DX) in the manufacturing industry in the engineering chain.

DIPRO, a member of the Fujitsu Group, has now joined this joint project. Thus, the three companies have agreed to further strengthen their organization for providing PLM systems.

About the Collaboration

1. Optimal solutions through combined know-how

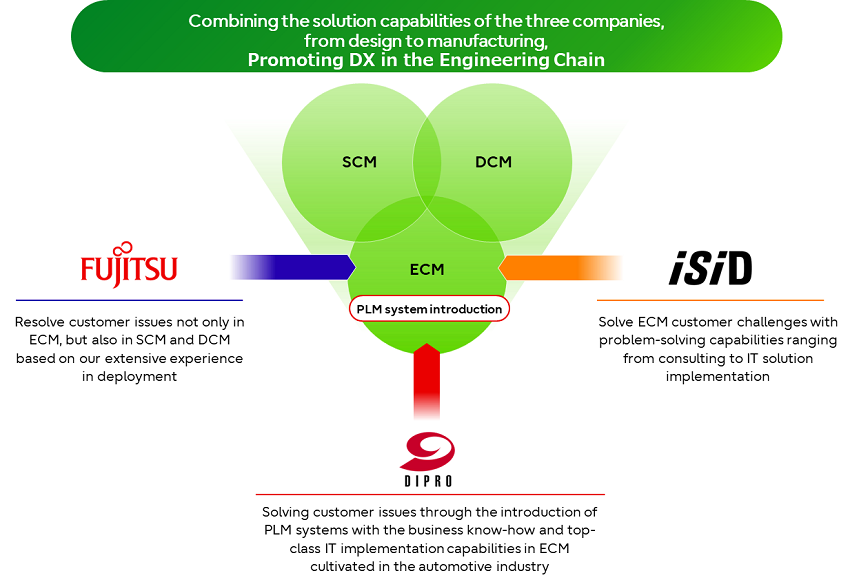

The collaboration will combine the three companies’ know-how. Particularly, Fujitsu has clout in the introduction of ECM, SCM, and DCM solutions (2). The partnership will also leverage ISID’s capabilities in areas that cover the entire spectrum from ECM consulting to IT solutions. Finally, it will also have DIPRO’s expertise in ECM business and IT implementation capabilities cultivated in the automotive industry.

The three companies will offer customers optimal solutions based on the introduction of PLM systems with a special focus on “Teamcenter.”

In addition to addressing challenges in the engineering chain, the three companies will further combine their respective solutions to contribute to the resolution of challenges across the supply chain and demand chain.

2. Training of PLM system engineers

Based on their experience in the introduction of “Teamcenter,” the three companies will collaborate in the training of Fujitsu Group engineers. The partners will further form a project team of trained engineers to respond to large-scale introduction projects in a wide range of fields. At the same time, build an organization capable of providing high-quality services in a short period of time.

Future Plans

Moving forward, Fujitsu, ISID and DIPRO will accelerate their collaboration across the entire engineering chain including the provision of PLM systems. Furthermore, it will support the promotion of DX in the Japanese manufacturing industry and contribute to international competitiveness. Particulary, by focusing on the coordination between the supply and demand chains.

Fujitsu will further continue to promote its vision for “Sustainable Manufacturing,” one of seven Key Focus Areas under its global business brand Fujitsu Uvance. Under the vision of “HUMANOLOGY for the future ~ Building beyond with people and technology. ~”

ISID will support companies, consumers, and society in solving problems through IT solutions created with technological capabilities and human attractiveness. Meanwhile, DIPRO will contribute to the sustainable development of manufacturing by supporting customer innovation in manufacturing processes. Moreover, it will combine “Monozukuri and IT”, “dissemination of software originating in Japan”, and “responsibility for results.”

Notes:

- [1]Siemens Digital Industries Software :

Headquarters: Shibuya, Tokyo; Japan Country Manager: Kunihiko Horita - [2]ECM/SCM/DCM :

Abbreviation of Engineering Chain Management, Supply Chain Management, and Demand Chain Management.