ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

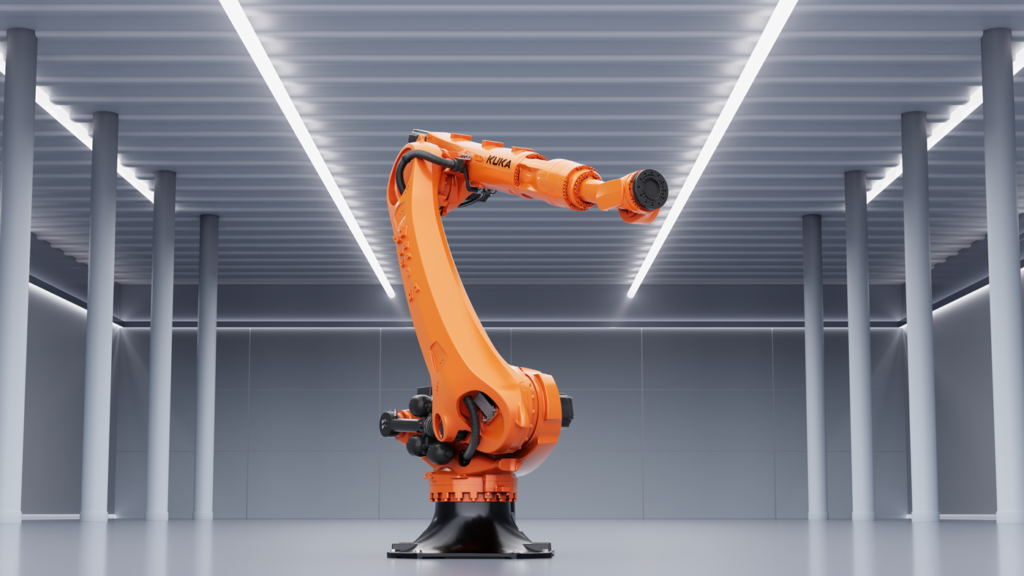

New KUKA Robot Offers Lower TCO in Small Footprint

The KUKA KR FORTEC industrial robot delivers great versatility in a small footprint. With high dynamic performance, it achieves short cycle times. Also, its compact shape makes it ideal for tasks such as handling and spot welding. The speedy KR FORTEC tackles all this with low energy consumption.

Achieve Lower TCO

This time, KUKA makes available the new KR FORTEC industrial robot featuring an extended arm that handles loads of 240kg across a reach of 3700mm. Technically, this heavy-duty robot fits between the KR QUANTEC and KR FORTEC ultra models. Cross-model modularization ensures a high transmissibility of robot series components.

“We developed the KR FORTEC to achieve a lower total cost of ownership (TCO) and to launch a resource-saving product on the market. The KR FORTEC is up to 700kg lighter than its predecessor,” explained Maximilian Pettkuhn, Portfolio Manager at KUKA. For customers, modularization means lower costs for spare part storage.

Service-proven KUKA Quality

Mainly, the KR FORTEC exemplifies reliability, with a long, trouble-free operating time and low maintenance requirements. Optimized accessibility makes maintenance work effortless and quick. Also, the two in-line wrists adopted from the KR QUANTEC and KR FORTEC ultra models are waterproof and dustproof as standard equipment. Beyond that, the KR FORTEC can operate between 0 to 55° C. Moreover, several foundry variants are available for harsh and dirty environments.

Greater Reach via the Linear Axis

Additionally, the working envelope of the KR FORTEC is expandable with the KL 4000 linear unit – which is modularly adaptable between 1.5m and 30m. Also, a further advantage is that the KR QUANTEC fits on the KL 4000. For cooperation with the KR FORTEC ultra on the same linear unit, the KL 5000 is simply selected. Accordingly, this allows customers to continue to adapt and combine products easily to meet individual requirements.