ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Nokia's Industrial Edge Solution Boosts Industry 4.0

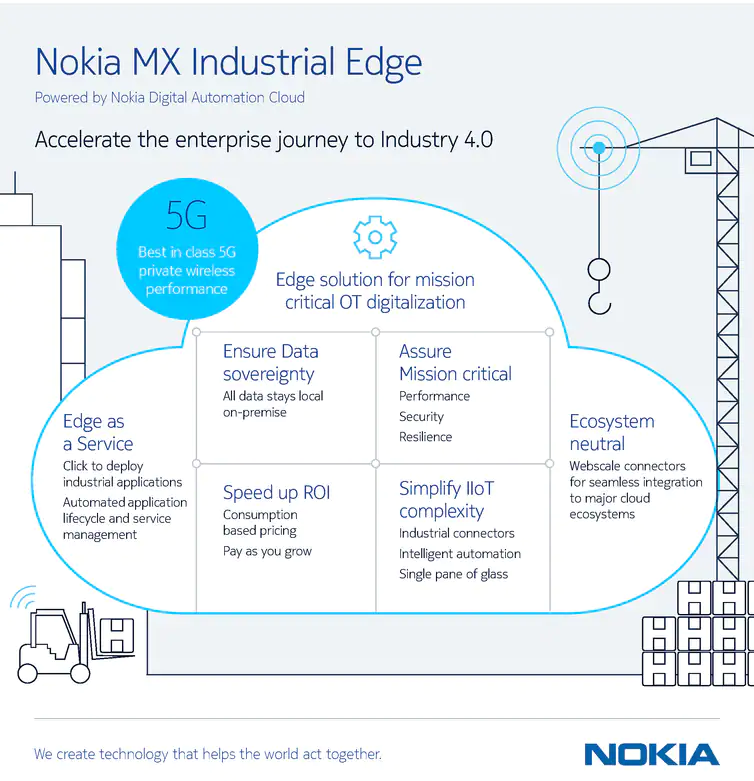

Nokia has introduced an industrial edge solution that will help enterprises accelerate operational technology (OT) digitalization and advance Industry 4.0. The new Nokia MX Industrial Edge is a scalable application and compute solution designed to meet the mission-critical digital transformation needs of manufacturing, energy, and transportation.

It uniquely combines compute, storage, wired and wireless networking, one-click industrial applications, and automated management into a unified, on-premise OT digital transformation platform.

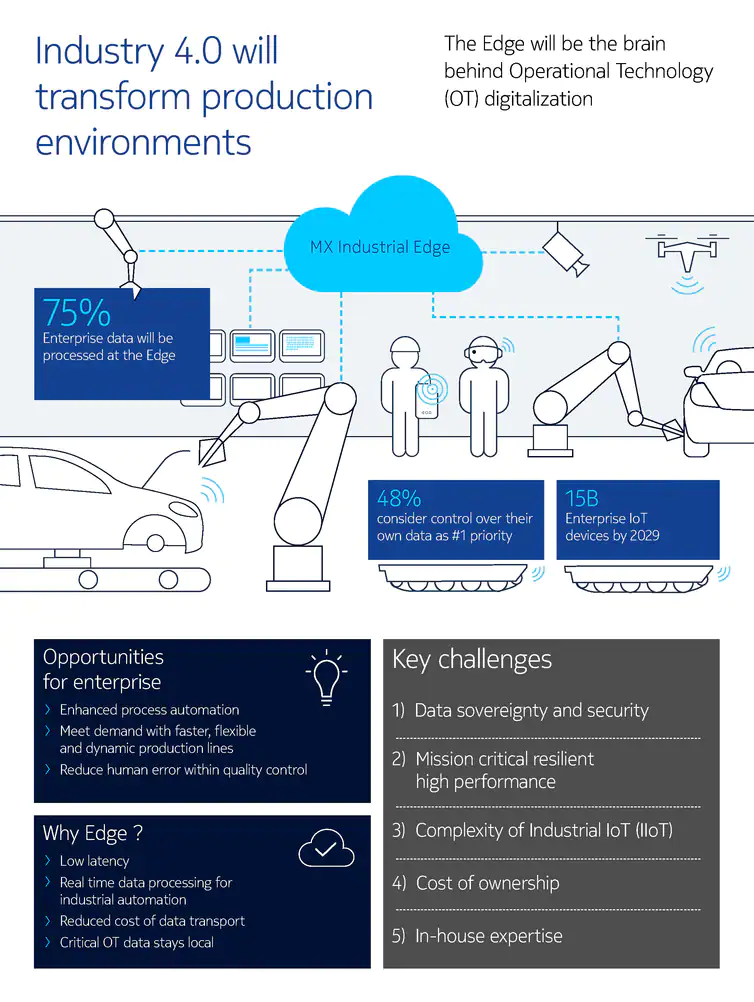

Industry 4.0 requires widespread digitalization and connectivity of equipment, machines, and other assets in industrial environments. Processing of data at the edge is necessary for real-time automation. By 2025, Gartner predicts that 75 percent of industrial data processing will take place at the edge.

Delivers Guaranteed Performance

With Nokia MX Industrial Edge, enterprises will benefit on-premises cloud architecture that unifies edge requirements in an easy-to-use, deploy everywhere, as-a-service package. It removes the complexity, knowledge, and economic hurdles typically associated with deployment, integration and life cycle management of high-performance applications and mission-critical networking.

The platform’s extreme scalability enables multi-facility enterprises, such as logistics companies, to deploy the same technology in all their locations, whether large or small, making the benefits of ‘develop-once, deploy-everywhere’ a reality. Nokia Digital Automation Cloud (Nokia DAC) powers the Nokia MX Industrial Edge, providing the enterprise a single pane of glass user experience to manage everything from applications to private wireless networking.

Stephan Litjens, Head of Enterprise Solutions at Nokia, said, “Industry 4.0 is transforming asset-intensive industries by integrating and digitalizing all processes and systems across the industrial value chain. This will result in an explosion of data – and taking the right actions based on that data in near real-time will be critical to the success of digital transformation initiatives.”

“The Nokia MX Industrial Edge is built from the ground up to deliver the guaranteed performance, security and reliability that OT digitalization use cases require,” Litjens added.

The Nokia edge solution is also available for enterprises in combination with Nokia Digital Automation Cloud applications, such as High Accuracy Indoor Positioning, Plug and Play private wireless, or with Nokia’s alternative private wireless solution, Nokia Modular Private Wireless (MPW). Flexible consumption-based pricing models provide ‘pay as you grow’ subscription flexibility while minimizing upfront investments.

Supports Wide-Range Deployments

Nokia MX Industrial Edge comes in a variety of configurations to support small, medium, and large-scale industrial deployments. Based on the Nokia AirFrame Open Edge server, the Nokia edge solution suits compute-intensive tasks and advanced artificial intelligence/machine learning workloads optionally supported through graphic processing unit (GPU) support. The server leverages on Intel’s latest innovations and CPU for high-capacity processing,

In addition, high-performance network interface cards (NICs) and packet processing systems scale to support very large 5G standalone private wireless traffic flows. It offers extreme resilience and reliability through an end-to-end, high availability (HA) architecture, supports geographical redundancy (GR) for business continuity.

Caroline Chan, Vice President, Network Platforms Group and GM, Network Business Incubation Division, Intel, said, “The combination of Intel’s innovations and CPUs alongside Nokia’s MX Industrial Edge Platform and 5G technology will offer enterprise customers the ability to connect, deploy and manage their environments. Across different verticals, enterprises will benefit from the scalable performance and high-speed, low-latency reliable communications.”

Promotes Multi-Partner Environments

Enterprise customers can accelerate their OT digitalization initiatives with the one-click deployment of industrial applications on the MX Industrial Edge. The catalog contains Nokia applications for a variety of common digitalization use. It also complements applications from independent software vendors (ISV), which undergo an onboarding process testing reliability, performance, and security.

In addition, Nokia’s ecosystem-neutral approach also enables industrial customers to take advantage of edge cloud compatible applications present in hyperscale clouds, as well as industrial partner clouds.

Finally, the MX Industrial Edge also simplifies southbound IIoT system integration complexity with its industrial connectors providing industrial data protocols translation. Also, with the Nokia Integrated Operations Center, provides a single pane of glass view from all systems as well as helping create industrial automation workflows.

Litjens added, “All industrial and enterprise campuses, such as factories, logistics hubs, ports, etc. are multi-solution and multi-partner environments. By adopting an ecosystem-neutral approach and integration plug-ins, our customers get unparalleled flexibility and benefit from the widest array of applications and use cases to adopt innovations to advance their digital transformation.”