ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

3D Systems Offers New Compact Model of Leading Printer

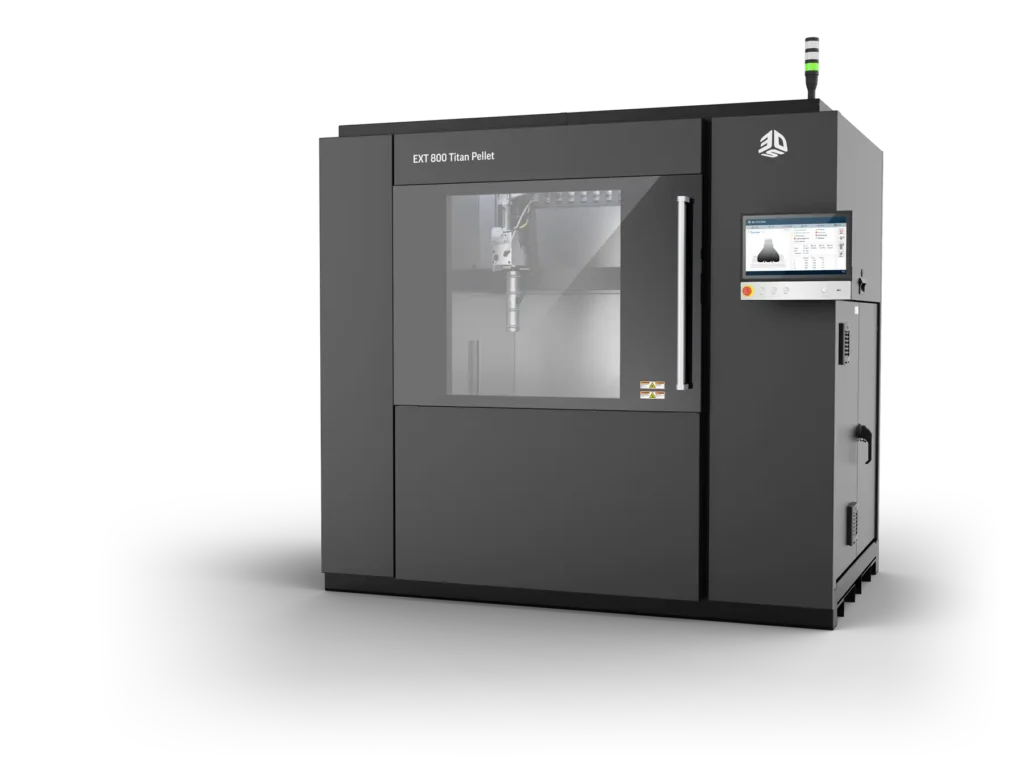

3D Systems, Inc. has announced the addition of the EXT 800 Titan Pellet to its industry-leading portfolio of EXT Titan Pellet systems.

Mainly, the new pellet extrusion system accommodates build sizes of 800×600×800mm. Also, it delivers the speed, reliability, and efficiency of 3D Systems’ large EXT Titan Pellet systems (EXT 1070 Titan Pellet and EXT 1270 Titan Pellet), thus reducing the initial investment in a more compact size.

Faster Print Speeds at Lower Cost

This allows manufacturers to take advantage of the fully automated, production-ready EXT 800 Titan Pellet to produce smaller functional prototypes, molds, fixtures, sand casting patterns, thermoformed molds, and end-use parts. With print speeds up to 10 times faster and material costs reduced by one-tenth compared to traditional filament-based systems, the EXT 800 Titan Pellet is designed to be efficient and cost-effective for applications in a wide range of markets; among them include foundry, aerospace and defense, thermoforming, prosthetics and footwear, and research.

“The addition of the EXT 800 Titan Pellet to our industry-leading line of pellet extrusion systems allows us to bring this technology to more manufacturers and strengthen their products and innovations,” said Rahul Kasat, Vice President of Titan at 3D Systems.

“For manufacturers looking for speed and sustainability, our EXT Titan Pellet system is a game-changer. Combining high-speed printing with cost-effective pellets, this technology is suitable for a wide range of applications.

For many years, customers have been looking for solutions to meet their needs to produce smaller parts at reasonable production costs. Particularly, the new EXT 800 Titan Pellet suits manufacturers who are looking for these benefits, but don’t need the massive build capabilities of their existing systems.

“We are confident that the EXT 800 Titan Pellet, combined with fast and high-quality printing, space savings, and low initial investment, will make it an attractive solution for a wide variety of industrial applications,” commented Kasat.

“This new product launch also demonstrates that 3D Systems is developing innovative solutions that will keep our customers ahead of the curve.”

Suits Wide Range of Manufacturing Environments

The EXT 800 Titan Pellet is ideal for a wide range of manufacturing environments, including offices, laboratories, universities, and large factories, thanks to its single extrusion tool head and sleek industrial design.

Particularly, the printer’s compact frame allows it to pass through standard double doors, making it easy to load in and install. Also, the device features a large front touch screen for an intuitive user experience.

In addition to the features of the new system in the EXT 800 Titan Pellet, customers who integrate this pellet extrusion system into their manufacturing environment will benefit from the same performance features as 3D Systems’ EXT 1070 Titan Pellet and EXT 1270 Titan Pellet large pellet extrusion printers.

Collectively, the industrial CNC controllers for reliable applications, heated beds and chambers for high-precision parts as well as the company’s proven pellet extrusion hardware and materials and the technology used in this 3D printer portfolio, the company has achieved print speeds up to 10 times faster than traditional filament prints, reducing material costs by a factor of 10.

In addition, by heating the bed and chamber, customers can use high-temperature-resistant engineering materials filled with glass and carbon, such as ABS, PC, nylon, PEI, and PEKK, as well as highly flexible TPEs and TPUs that cannot be printed on filament-based machines.

The EXT 800 Titan Pellet is available to order now. The first shipment of the printer is expected in the third quarter of 2024.

This is an online translation of a Japanese press release with slight editing made by Dempa.

-17 July 2024-