ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yaskawa Launches First Adaptive Robot Series

Yaskawa Electric Corporation is accelerating the development of i3-Mechatronics. Specifically, this solution concept is based on the utilization of digital data at factories and other facilities using mechatronics products. Among them are industrial robots and servo drives. With this concept, Yaskawa aims to realize a new industrial automation revolution.

Today, Yaskawa is pleased to announce the launch of MOTOMAN NEXT Series as one of the key components of i3-Mechatronics. Specifically, the MOTOMAN NEXT Series consists of five models with payload capacity of 4kg, 7kg, 10kg, 20kg, and 35kg. Mainly, this next-generation robot is the first in the industrial robot sector to autonomously adapt to the environment and make judgments.

*Based on the company’s survey among major robot manufacturers

Aim of Product Launch

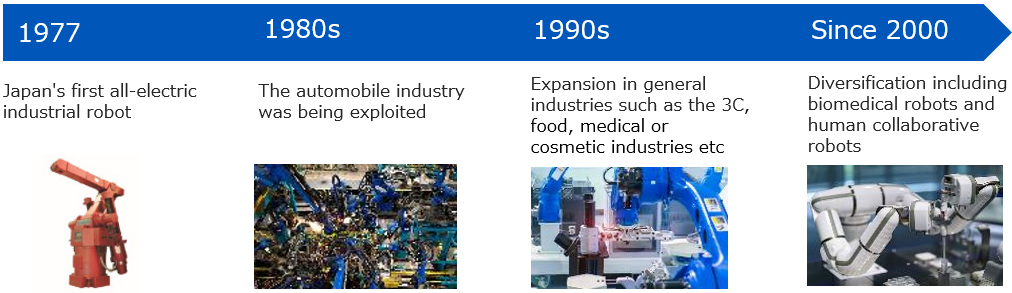

Yaskawa developed Japan’s first full electric industrial robot in 1977. Since then, it has expanded the robotics business into a growing industry, responsive to the present needs. Particularly, these include the automotive industry, expansion of application markets such as the 3C, food, medical, or cosmetic industries, and enhancement of functions for optimal manipulators for e.g. biomedical robots and collaboration robots.

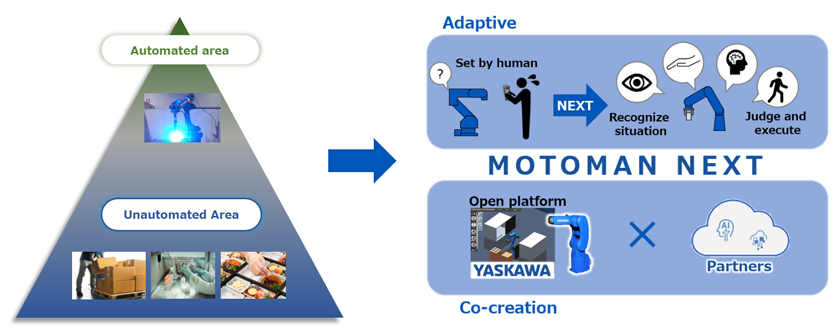

To date, the number of installed industrial robots continues to grow. This is the result of advances in basic performance, such as robot motion speed and payload capacity, and progress in application technology. On the other hand, a lot of “unautomated areas” until today adopt human judgment. Moreover, workers perform tasks such as indefinite state, shape, and size of items, changes in work order, and interruptions.

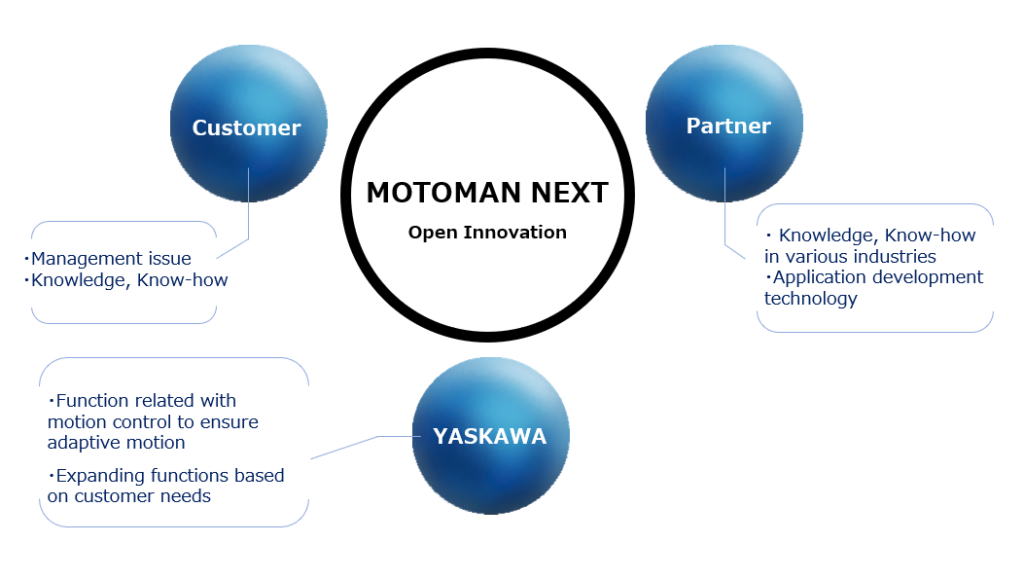

Mainly, the MOTOMAN NEXT Series challenges automation out of the “unautomated areas”. Thus, it aims to complete tasks in an optimal method by understanding the situation and making judgments and plans. It also provides an open platform that embeds customer and partner expertise to build solutions. It will work together with the customers and partners to accelerate automation. Moreover, they will solve social issues such as labor shortages in the factory automation (FA) field or other industries such as food, logistics and agriculture etc.

Main Features of the MOTOMAN NEXT Series

The MOTOMAN NEXT series realizes autonomous adaptivity and an open platform for creating solutions with customers and partners.

Realizing autonomous adaptivity

The MOTOMAN NEXT controller makes motion planning. Then, it executes it based on the recognition and judgment of the environment and position data acquired from the sensor. To this aim, it has adopted a new architecture that includes an autonomous control unit in addition to the control function of the robot itself. It also ensures autonomous adaptivity by checking the status of the task and completing it by recognizing the situation.

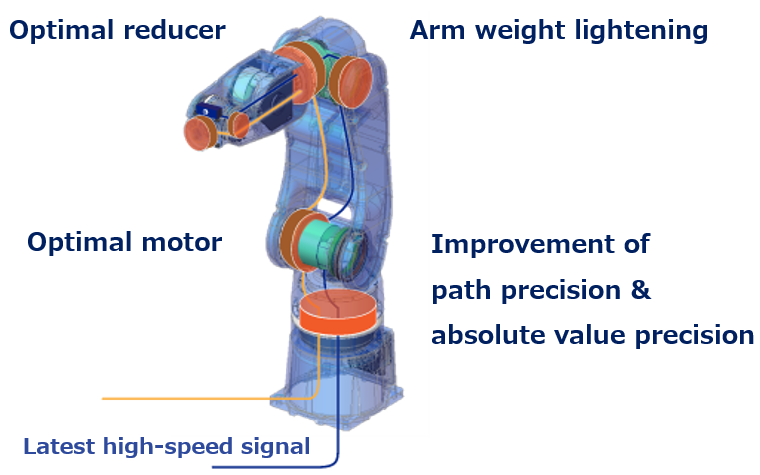

Additionally, the MOTOMAN NEXT manipulator adopts an optimal motor developed in-house to enhance its capability to follow commands from the controller. This allows improved basic performance and enables digital twins by minimizing the gap between the controller’s commanded position and the actual position. This manipulator is a closely integrated product of the latest motor technology and robot technology.

Open platform to build solutions with customers and partners

The MOTOMAN NEXT controller opens up the development environment for robot applications by utilizing the unique know-how and technologies of customers and partners.

The company will start introducing the five products in the commercial market this December sequentially.