ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Delta Lifts up Smart Manufacturing with New Cobots

At Hannover Messe 2024, Delta Electronics, Inc. announced a significant milestone in its development of smart manufacturing solutions. Mainly, it launched six highly versatile models in the D-Bot series of collaborative industrial robots (cobots). The portfolio features cobots with payload capacities up to 30kg, reach spans up to 1800mm, compatibility with EtherCAT, Modbus, and CODESYS, as well as the integration of 24-bit encoders. Accordingly, they ensure optimal levels of precision, especially in pick & place, welding, and palletizing applications.

“In the field of mechanical engineering and automation technology, collaborative robotics represents one of the fastest-growing sectors. Market researchers from Interact Analysis predict an annual growth rate of around 20 percent by 2032. We aim to meet this demand with our D-Bot Series cobots; thereby assisting our customers in optimizing their production processes, enhancing manufacturing efficiency, and mitigating labor shortages in many industries,” explains Michael Mayer-Rosa, Senior Director, Industrial Automation Business Group at Delta Electronics EMEA Region. “Having succeeded for many years as a provider of robotics and automation technology components, we are exceptionally well-positioned to make significant achievements in this area as well.”

A Full Range of Versatile Models

Particularly, the D-Bot series includes six versatile models: D-Bot 6, D-Bot 8, D-Bot 10, D-Bot 16, D-Bot 20, and D-Bot 30, with payload capacities ranging from 6 to 30kg. These models feature six axes for unmatched flexibility and precision. In relation, these models offer speeds up to 200 degrees per second and accuracy within ±0.02mm. Also, their reach spans 800 to 1800mm, suited for diverse operational demands. The integration of 24-bit encoders enhances precision, ensuring consistent performance.

Speed, Precision, Easy Integration, and Safety Combined

Additionally, Delta’s D-Bot Series is designed with IP66 protection and advanced safety protocols. Thus, they promise a secure and efficient workspace. They support interfaces like EtherCAT, Modbus and CODESYS. Also, these cobots are perfect for a range of tasks, from palletizing, pick & place, welding and more. With “Plug & Play” setup and intuitive programming via a user-friendly interface, the D-Bot series models are accessible to operators of all skill levels. Therefore, it promotes human-robot collaboration in sectors such as automotive, logistics and electronics.

Rapid Deployment and Easy Operation

Moreover, Delta’s D-Bot Series is designed for rapid deployment, requiring no special programming skills, making it operational in no time. Thanks to its “Plug & Play” feature, setting up movements and command executions is effortlessly achieved. Furthermore, the system facilitates teaching through drag & drop, Python, ROS 1, or C++, ensuring a simple and flexible operation. Also, the modern graphical user interface (GUI) features immersive 3D visualization. Thus, it allows users of all levels to quickly program. Also, the inclusion of an HMI panel in the package eliminates the need for additional devices or tools for control. Thus. it streamlines the operation process even further.

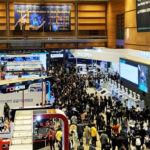

Delta officially launched the D-Bot series Cobots to the public for the first time on April 22 at the Hannover Messe in its booth, located in Hall 11, Stand C05. Also, the company will hold a press conference on April 23 at its booth at 1:30 PM. For more information, please visit: https://www.delta-emea.com/en-GB/landing/Cobot

-24 April 2024-