ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Orbray Zirconia Film Has Leading Surface Roughness

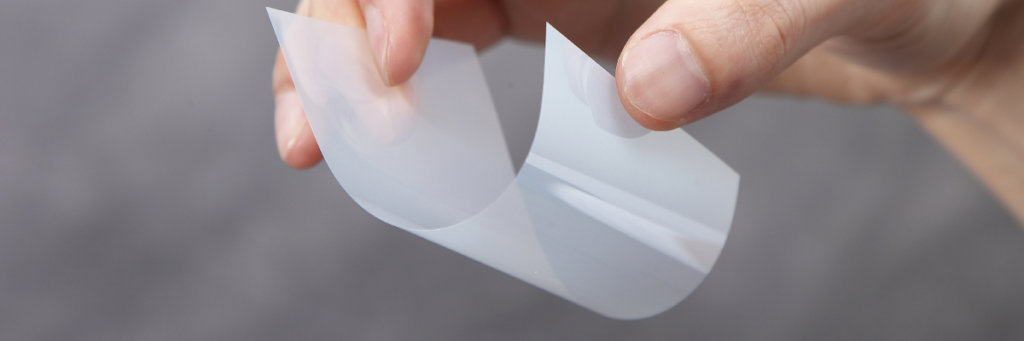

Orbray Co., Ltd. has successfully produced the industry’s first 20μm thick, flexible zirconia film with an exceptionally smooth surface.

Zirconia ceramic materials have excellent heat resistance, corrosion resistance, strength, wear resistance, and fracture toughness characteristics. Orbray has extended the potential applications for zirconia ceramics by using its ultra-thin polishing technology to create flexible zirconia film. In doing so, the company has also achieved surface roughness of Ra <5nm, a first in the industry.

Features Ultra-thin Polishing Technology

Mainly, this novel material finds uses in various applications, such as circuit and sensor boards, flexible heaters, heat-insulating films, and diaphragms. Additionally, the flexible zirconia film’s high dielectric constant and low dielectric dissipation factor make it suitable for creating antennas, supporting their miniaturization and integration into IC card substrates. While zirconia ceramics is known for its high strength, its brittleness is a drawback, as it tends to break when bent. However, polishing the surface very evenly using Orbray’s ultra-thin polishing technology gives the zirconia film flexibility.

Specifically, it features a 3-point bending strength of 1,000MPa and fracture toughness of 5MPa・√m. It has heat-resisting temperature of 1,200°C and thermal conductivity at 3W/m・K(20℃).

-17 May 2024-