ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Henkel Launches New Thermal Gap Filler for Automotives

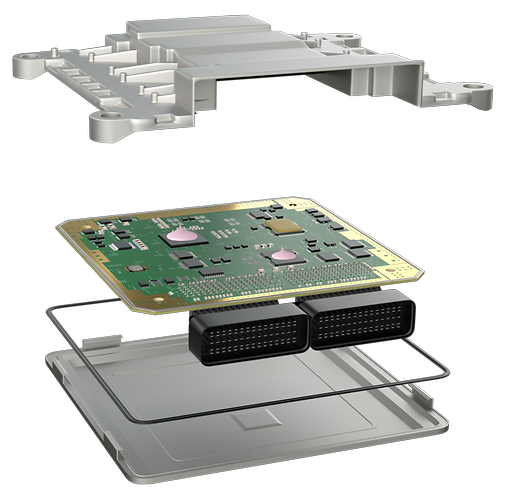

Today’s vehicles have become increasingly connected. Meanwhile, sophisticated ADAS and autonomous driving technologies transformed driving. Thus, OEMs and component suppliers are increasingly challenged to manage the heat produced by ECU and ADAS components. This ensures their performance and reliability. Also, there is a need to produce these components more cost-effectively, more sustainably, and with ever higher performance.

With its next generation of thermal gap fillers, Henkel Adhesive Technologies is helping to meet these intersecting challenges through innovative solutions tailored specifically for demanding automotive applications. Henkel is launching its next-generation range of thermal gap fillers with the offering of Bergquist gap filler TGF 4400LVO.

Specifically, Bergquist gap filler TGF 4400LVO is optimal for dispensing with a thinner bond line and for fast processing and high reliability. It is ideal for applications such as control units and ADAS components. This new thermal gap filler is a 2-component, room-temperature curable gap filler based on low volatile silicone technology.

“As an expert partner to the automotive industry, we are working closely with OEMs and component manufacturers. We develop new thermal interface materials and adhesives that meet the demands of the toughest, safety critical applications while improving efficiency and versatility,” said YM Bae, Business Development Manager at Henkel. “This generation of gap fillers delivers peerless combination of robust dispensing, high reliability, and variety of thermal conductivity options. New products that will address the broad scope of evolving requirements in automotive manufacture will follow the launch of Bergquist gap filler TGF 4400LVO.”

Moreover, Bergquist gap filler TGF 4400LVO provides an easily dispensed gap filler solution with a thin bond line that offers a high level of reliability in the face of thermal shock. It has a typical thermal conductivity of 4.4W/mK. With a very low volatile siloxane content, it provides a more sustainable choice that helps protect sensitive electronic components.

In a production environment, the fast-dispensing filler delivers greater efficiency and versatility. The long working time of >90 minutes also enables a wider process window and provides for sustainability benefits of reduced production line wastage. TGF 4400LVO cures at room temperature in 12 hours but curing can be accelerated with heat if required.