ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Solomon Unveils NVIDIA-Powered Humanoid Robot

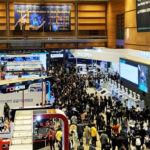

Solomon Technology Corporation has integrated NVIDIA’s Jetson Thor, Isaac GR00T VLA model, and Isaac Sim to develop a humanoid robot simulation system driven by natural language. The system was presented for the first time at Automation Taipei 2025, which ran from August 20 to 23, highlighting a major leap in AI-driven robotics.

Breaking Technical Barriers

Unlike traditional LLMs or VLMs, NVIDIA’s GR00T introduces “A” for action, enabling robots to execute tasks rather than just interpret text or images. This requires significant computing power. The previous Jetson AGX Orin struggled with these workloads, prompting NVIDIA to release Jetson Thor with three to four times greater performance. As an NVIDIA partner, Solomon quickly adopted Thor, successfully combining VLA and Isaac Sim to create a training pipeline where humanoid robots first learn in virtual environments before transitioning to physical execution.

From Simulation to Reality

Despite these breakthroughs, humanoid robots still face challenges in dexterity, training efficiency, and system integration. Unlike industrial robotic arms, which are limited to a few axes and rely on mathematical models for control, humanoid robots have over 40 axes, making conventional approaches impractical. AI is therefore essential to teach them complex actions. Solomon enhances this with its proprietary vision technology, giving robots sharper object recognition and faster decision-making capabilities.

Superhuman Vision for Practical Use

Solomon foresees humanoid robots gaining traction in inspection and monitoring. Equipped with long-range vision and strong AI reasoning, they can detect small objects or read parameters from several meters away—tasks that conventional inspection systems or robotic dogs struggle with. This opens opportunities in factory equipment monitoring, predictive maintenance, and large-scale infrastructure inspection.

AR + AI Beyond Manufacturing

The company is also advancing AR + AI integration. With AR glasses, operators can be guided step by step, reducing errors. In finance and insurance, AI can automate the processing of handwritten documents, while in semiconductors and healthcare, it can verify incoming materials in supply chains. These solutions go beyond visualization, delivering tangible efficiency gains across industries.

3–5 Year Roadmap

Looking ahead, Solomon is building ready-to-deploy AI automation solutions by combining inspection software, robotics, and motion control into unified platforms. Such systems will accelerate defect detection for complex objects across semiconductors, automotive, medical devices, and even luxury goods. To meet rising demand, Solomon plans to expand its global presence, potentially moving its U.S. base from California to Texas and establishing FAE support in Mexico to serve both North and South America.

24 August 2025