ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

FANUC Unveils Basic Platform for Digital Manufacturing

FANUC Corporation has introduced the FIELD system Basic Package, a packaged product that can easily start improving production sites. Specifically, it is a platform that creates value by connecting production sites (real world) and computers (digital world) with data.

The FIELD system Basic Package supports manufacturers to start visualization of production sites from the first day of installation. In particular, it offers the “simple setting” and “operation monitoring” functions. It is also expandable depending on the user’s usage proficiency and stage of problem-solving at the production site. In addition, the Basic Package continuously supports improvement of activities from operation monitoring to linkage with external systems.

Features of FIELD System Basic Package

The FIELD system Basic Package keeps the concept of FIELD system, while pursuing easy adoption and ease of use of data for users.

The packaged product integrates hardware and software and features a pre-installed software. It is an on-premise type that does not require connection to Internet. Moreover, it has the same level of high reliability and lifetime maintenance as FANUC CNC.

It also offers easy connection to equipment through the connection function for FANUC CNC-equipped machine tools. Moreover, it has built-in data collector software.

Additionally, the system is installed with apps for operation, quality and maintenance. They can be customized and support the production-site-oriented “KAIZEN”. These apps quickly adapt the system according to work environment and changes.

It also has an integrated database specified for manufacturing sites. Specifically, it enables centralized management of data from various devices. It features a data model that allows the easy use of collected data. The system also enables cooperation with an external system. Moreover, it links data collected from devices with in-house host systems, commercial ERP and MES. It is powered with security features to protect the data.

Continuous System Updates

The FIELD system and its constituent software components are continuously improved. Meanwhile, data security is available under the new environment. Moreover, the FIELD system Basic Package can be updated to the latest version via the user’s PC without connecting directly to the Internet.

Packaged Product and Lifetime Maintenance

The FIELD system Basic Package consists of a set of software that supports productivity improvement at the production site. It is provided as a ready-to-use packaged product.

While using the FIELD system, FANUC will provide support to users for the hardware and software.

Data Platform Technology that Supports FIELD system Basic Package

The FIELD system Basic Package has a 3-layer structure. It supports the expandability required for improvement activities at production sites from the ground up. Moreover, it continuously supports improvement of activities in manufacturing sites.

Main Functions of FIELD system Basic Package (Collect → Analyze → Utilize)

Collect and organize production site data with easy connection

Once production equipment is networked, engineers can start collecting data with just a few clicks.

The FIELD system Basic Package stores various production data as a “standardized common data model.” It centrally manages it in the integrated database. Users and applications can use the data without concern on the different data structures for each manufacturer and machine.

All-in-one package for easy data organization and analysis

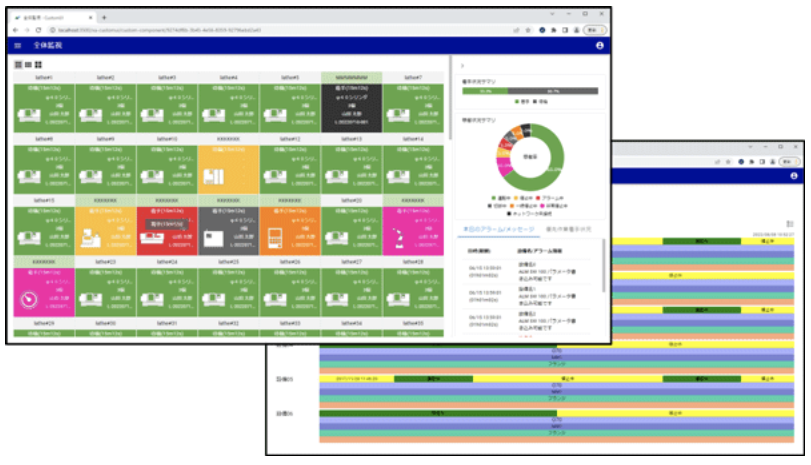

The organized data of the integrated database can be visualized and analyzed by KAIZEN support tool packed in the FIELD system Basic Package. With just a few clicks, users can see the data with the KAIZEN support tool.

More advanced utilization of production data by linking with external systems

The FIELD system Basic Package can be securely linked to external systems. This process will create a cycle that utilizes equipment data and business data from the production site.