ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

DEN-ON to Pitch Development, Rework Solutions

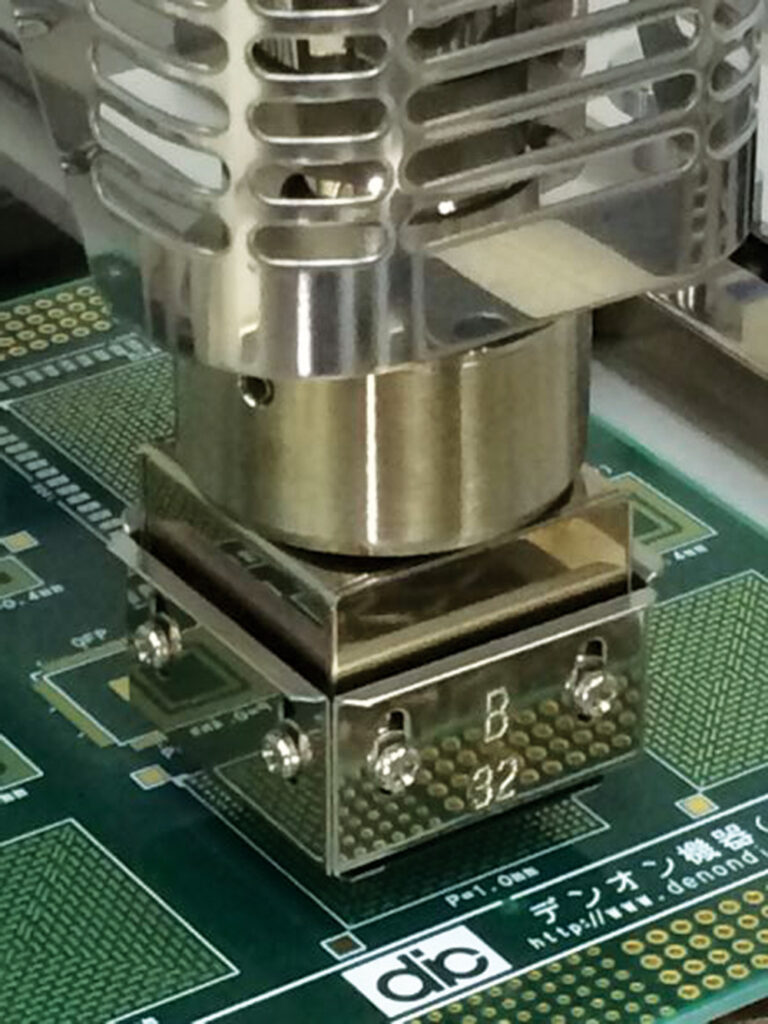

At IPC APEX EXPO, DEN-ON INSTRUMENTS, CO., LTD. will showcase the RD500V Series development and rework machine. RD500V Series is an advance model for handling complex, very densely populated, multilayer, of about 50 to 100 layers, large printed circuit boards (PCBs).

IPC APEX EXPO takes place January 24 to 26 in San Diego, California, U.S.A.

RD-500V Series Development and Rework Station

DEN-ON will present a complete line of the RD-500V Series development and rework stations featuring its ultra high definition camera with a 19-inch LCD panel for easy visual alignment. All the RD500V Series rework stations are built with powerful 1000W localized convection Z controlled heaters on both the top- and bottom-side. They are also equipped with an area heater that can range from 2.4 to 4.8KW quick heating infrared heaters. Also, they can execute precise profiling including detailed temperature curves by closely controlling and editing up to 30 zones individually.

The machines’ closed loop heating control can sample the data in very small intervals of 0.1 sec, allowing extremely accurate temperature management.

Furthermore, the RD500V model on display will include an all-in-one technology that can handle the smallest components from 01005 to the largest.

They will be displayed with the company’s advanced tools for future technology. These include:

- Three-Point Auto Profiling

- On-the-Fly Profiling

- Zone Profiling

- Programmable Placement Force

- Programmable Micro Placement

- Speed Control

- Product Tracker

- Alignment Vision Save

- Self-Contained Nitrogen Generator

- Side View Camera for solder joint inspection during process

SDR-1000 Fully Automated Development, Rework Station

DEN-ON has also announced a new addition to its lineup of tools. The SDR-1000 fully automated development and rework station includes the company’s latest innovation for very challenging processes. In addition, this feature is the company’s proposed solution to fully automate development and rework process.

All these advanced products are available at DEN-ON’s booth at Booth #3022.