ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

ENEOS Materials Taps Yokogowa’s Autonomous Control AI

ENEOS Materials Corporation and Yokogawa Electric Corporation have to use the latter’s Factorial Kernel Dynamic Policy Programming (FKDPP), a reinforcement learning-based AI algorithm. Particularly, ENEOS Materials chemical plant will employ the AI control system.

The agreement follows a successful field test in which this autonomous control AI*1 demonstrated a high level of performance. Whereas, controlling a distillation column at this plant for almost an entire year. This is the first example in the world of reinforcement learning AI being formally adopted for direct control of a plant*2.

Demonstrate Four Benefits

Over a 35 day (840 hour) consecutive period, from January 17 to February 21, 2022, this field test initially confirmed*3 that the AI solution could control distillation operations. Previously, this was beyond the capabilities of existing control methods (PID control/APC) and had necessitated manual control of valves based on the judgements of experienced plant personnel. Following a scheduled plant shutdown for maintenance and repairs, the field test resumed and has continued to the present date.

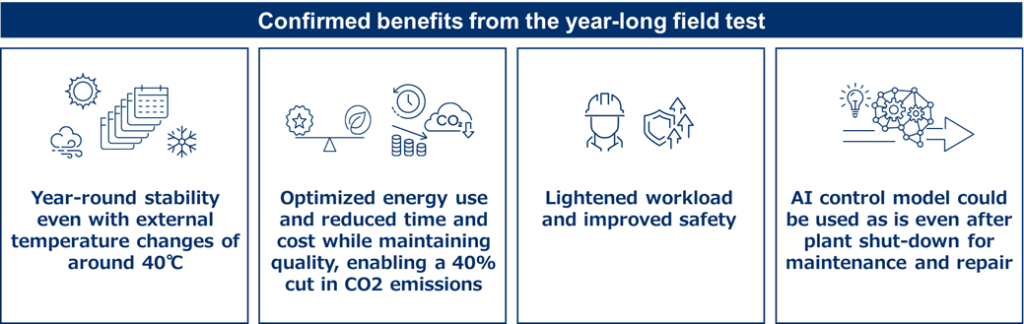

In this field test, the autonomous control AI demonstrated the following four benefits:

Moreover, it has been conclusively shown that this solution is capable of controlling the complex conditions needed to maintain product quality and ensure that liquids in the distillation column remain at an appropriate level, while making maximum possible use of waste heat as a heat source. In so doing it has stabilized quality, achieved high yield, and saved energy.

- Year-round stability

The autonomous control AI maintained stable control of the liquid levels and maximized the use of waste heat, even in winter and summer weather, with external temperatures changes by about 40ºC. No problems were observed, and stable operation and high product quality was achieved throughout the field test. - Reduced environmental impact

By eliminating the production of off-spec products, the autonomous control AI reduced fuel, labor, and other costs, and made efficient use of raw materials. While producing good quality products that met shipment standards, the autonomous control AI reduced steam consumption and CO2 emissions by 40%*4 in comparison to conventional manual control. - Lightened workload and improved safety

The autonomous control AI eliminated the need for operators to perform manual inputs. This not only decreased workload and helped to prevent human error, it also reduced mental stress levels and improved safety. - Robustness of the AI control model

Even after modifications were made at the plant during a routine shut-down for maintenance and repair, the same AI control model could remain in use.

Stable, Optimized Performance

ENEOS Materials found over the course of this one-year verification process that the autonomous control AI was a robust system. Hence, could achieve stable performance and optimize operations throughout the year, including in winter and summer.

The company will look into applying this AI to other types of processes and plants. Furthermore, will continue working to improve productivity and save energy by expanding the scope of autonomization.

To promote plant autonomization, on February 27 Yokogawa launched the provision of an autonomous control AI service for edge controllers*5, also a world first*6. In conjunction with this service, the company is offering customers who wish to achieve autonomous plant operations a global consulting service that covers everything from the identification of control issues to the investigation of optimum control methods and the calculation of cost-effectiveness, and includes safety, implementation, maintenance, and operation.

Going forward, ENEOS Materials and Yokogawa will continue to work together and investigate ways to carry out digital transformation (DX) through the use of AI for control and condition-based maintenance in plants.

Notes:

*1 Yokogawa defines autonomous control AI as AI that deduces the optimum method for control independently and has a high level of robustness enabling it to autonomously handle, to a certain extent, situations that it has not previously encountered.

*2 Based on comprehensive secondary research of publicly available resources by IoT Analytics, performed in March 2023.

*3 In a World First, Yokogawa and JSR Use AI to Autonomously Control a Chemical Plant for 35 Consecutive Days – Putting into practical use a next-generation control technology that takes into account quality, yield, energy saving, and sudden disturbances –

*4 In comparison to the amount of steam previously used to maintain the liquid level and the corresponding amount of CO2 emissions.

*5 Yokogawa Launches Autonomous Control AI Service for Use with Edge Controllers – Optimizes control to improve productivity and save energy –

*6 As the world’s first commercially available reinforcement learning AI service for edge controllers. Based on comprehensive secondary research of publicly available resources by IoT Analytics, performed in March 2023.