ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Sensing Unit Bolsters Production Maintenance

Yokogawa Electric Corporation has developed the OpreX Multi-Sensing Remote I/O as an addition to its OpreX Components lineup. OpreX Multi-Sensing Remote I/O devices accurately obtain data from multiple sensors, convert it to a digital format, and transfer it to a higher-level system for monitoring.

OpreX is the comprehensive brand for Yokogawa’s industrial automation (IA) and control business. The OpreX name stands for excellence in the technologies and solutions that Yokogawa cultivates through the co-creation of value with its customers.

The first model in the portfolio the VZ20X Analog Sensing Unit, which the company released to 64 countries on August 31. The smallest-in-class VZ20X is a high-speed, high-precision, and highly noise-resistant device that is capable of simultaneously collecting data from analog sensors on up to 120 channels. With a height and width less than that of a standard business card and weighing less than 200g, it is suitable for installation wherever space is at a premium, including on production equipment.

Leveraging such characteristics and the capabilities of Yokogawa’s AI technology, users of the VZ20X will be able, for example, to detect when an abnormality is likely to occur on a production line. It can perform condition-based maintenance at a suitable time.

The VZ20X is also able to accurately collect data needed for the development of components such as the on-board batteries used in electric vehicles (EVs), plug-in hybrid vehicles (PHVs), and fuel cell vehicles (FCVs).

Development Background

Yokogawa Electric acknowledges the need for a compact, high-speed, and high-precision device capable of simultaneously collecting data from multiple sensors.

While unmanned transport vehicles, advanced automation, and other technologies are increasingly being used to reduce labor costs at logistics and production facilities, there are areas where equipment and processes are managed using analog technology. Detecting early signs of deterioration in such facilities is a challenge, and failures can lead to unplanned shutdowns and reduced operating rates. With CBM, there is an increasing need for compact devices to retrofit existing facilities and solutions to enable the rapid and accurate collection and digitalization of event-driven data from multiple locations.

The world is seeing innovation in the automotive technologies used in EVs, PHVs, FCVs, and other vehicle types. To ensure high-quality outcomes in the development of components such as automobile batteries and in the conduct of environmental and performance tests, it is important to obtain highly reliable data. As such, it is necessary to simultaneously collect data from multiple sensors at high speeds and with a high level of precision.

Features

World-class compact design

Shorter and narrower than a business card and weighing less than 200g, the VZ20X is suitable for installation in tight spaces. It also minimizes the need to reconfigure existing production equipment, making it suitable for mounting on unmanned transport vehicles and other vehicle types for the running of battery performance assessments, performance of preventive maintenance, among others.

The product also allows easy connection of devices using push-in connections and ferrule terminals. Power supply is via Type C USB.

High-speed, high-precision, multi-channel synchronization, and high noise resistance

Analog input signals can be sampled at high speed of 1msec (0.001 seconds) intervals.

Synchronization accuracy is at ±100msec (1msec = 1 millionth of a second), with high precision measurement accuracy of ±0.05 percent, temperature measurements accurate to within ±0.16℃ or less, and voltage measurements accurate to ±1mV.

With each module having 8 channels, they can connect to a maximum of 15 units, enabling simultaneous measurement across up to 120 channels. It exhibits high noise resistance also because input channels have good insulation quality, enabling even in a noisy environment.

Support for a range of analog sensors

A single module can accept a wide range of analog inputs including DC voltage signals, unified signals, resistance signals, and temperature signals from sensors such as thermocouples (TC) and 3-wire/4-wire resistance temperature detectors (RTD). By accommodating inputs from a variety of analog sensors, it facilitates the monitoring and control of a wide range of variables including voltage, temperature, humidity, pressure, and vibration.

Applications, Typical Uses

Major target markets of the OpreX Multi-Sensing Remote I/O include transport and logistics, automobiles and machinery, electronic devices, energy and materials, and food and agriculture. Specific applications include obtaining precise data from multiple sensors and forwarding it to higher-level systems that perform monitoring, particularly in CBM of facilities in production and logistics sites. It is also applicable on testing and research and development institutes, on the performance assessment tests in product development processes and safety and reliability tests in product quality inspect processes.

Among the typical use cases of OpreX Multi-Sensing Remote I/O include the following:

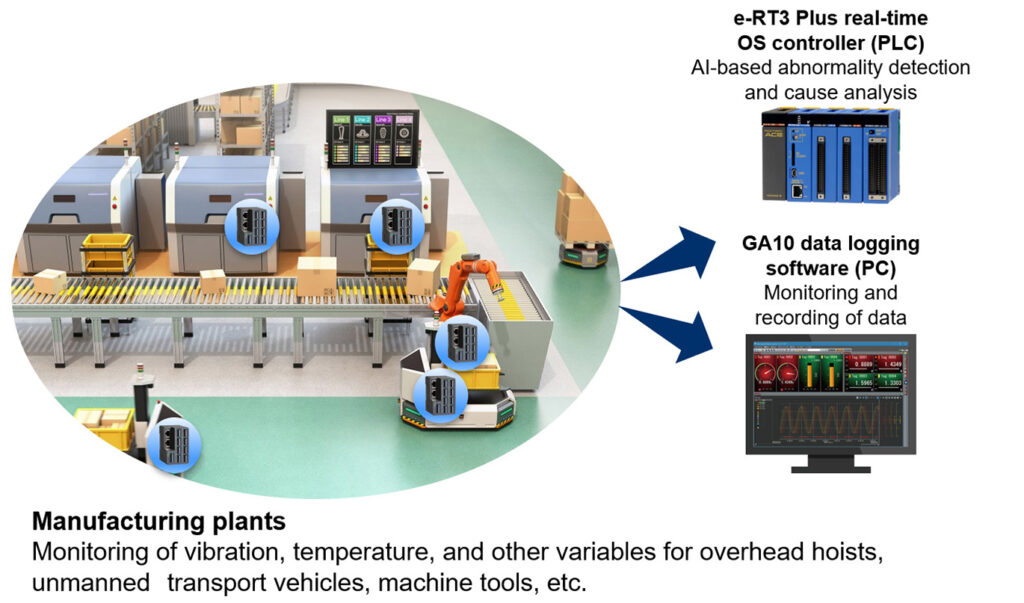

Maintenance of production/logistics facilities

Extremely compact and light, the module can easily be mounted on unmanned transport vehicles, production lines, and the like. When used together with the GA10 data logging software and the e-RT3 Plus real-time OS controller, this device not only facilitates high-precision data gathering and monitoring but also is able to utilize Yokogawa’s proprietary AI technology to perform abnormality detection and cause analysis. This leads to reduced downtime and improves operational efficiency. GA10 data logging software is a PC-based data logging application that utilizes an Ethernet network to collect and record data from devices throughout factories and other facilities.

Development of components

When used in combination with the GA10 software, the module enables the fast and precise collection and monitoring of synchronized data from multiple channels needed to ensure high quality outcomes in the testing and development of automobile components. Furthermore, thanks to its excellent noise resistance, this product can accurately gather data even when the device under test, such as an inverter (power converter), is a noise source.

Automobile environmental, performance, and reliability testing

This module ensures quality outcomes in endurance and environmental tests by enabling the synchronized and highly precise collection and monitoring of data on variables such as temperature, humidity, pressure, and dew point that impact the vehicle operating environment.