ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Mitsubishi Electric High-Voltage IGBT Module to Hit Market

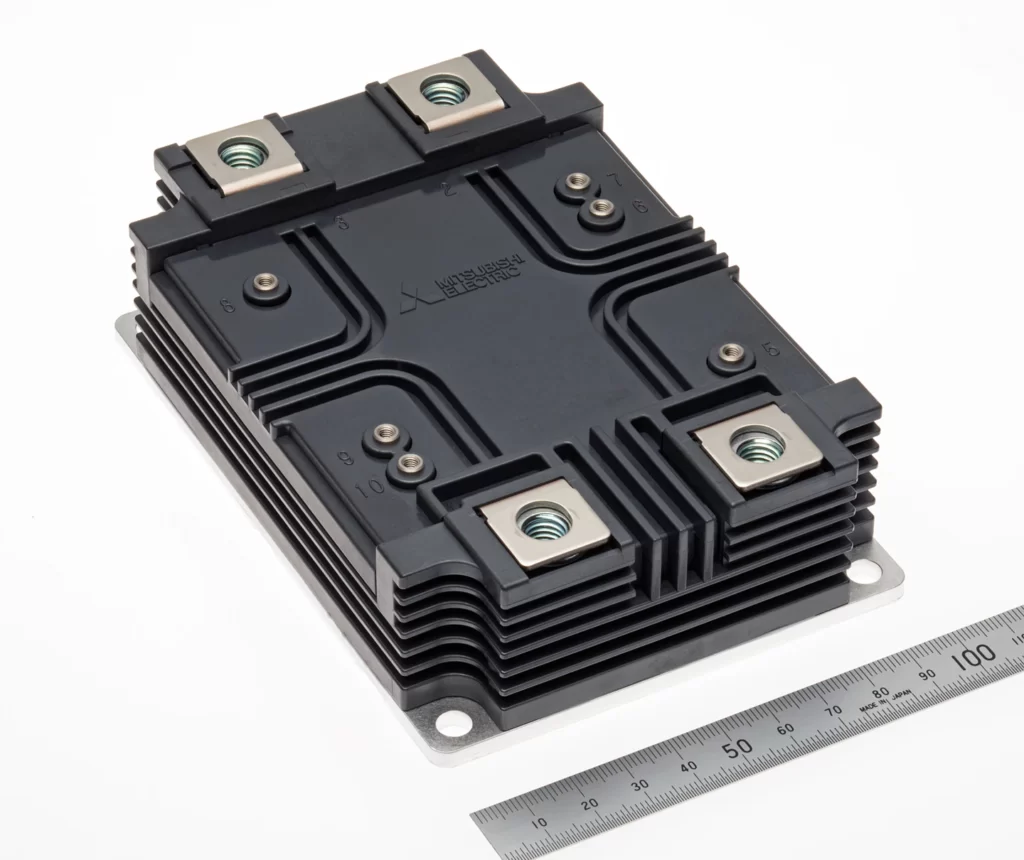

Mitsubishi Electric Corporation will begin shipping samples of the new HV100 dual-type X-Series high-voltage insulated gate bipolar transistor (HVIGBT) module on May 31. This latest product offers superior power, efficiency and reliability in inverter systems for large industrial equipment, such as railways and electric power systems.

Specifically, the dual-type module achieves 4.5kV withstand voltage and 10.2kVrms dielectric strength. It is rated at 450A, which is believed to be unmatched among 4.5kV silicon HVIGBT modules.1 The product will be exhibited at major trade shows, including Power Conversion Intelligent Motion (PCIM) Europe 2023 in Nuremberg, Germany from May 9 to 11.

Power Semiconductors in Heavy Industries

Power semiconductors are increasingly being utilized to efficiently convert electric power in order to lower the carbon footprint of global society. This is particularly true in heavy industry, where these devices are used in power-conversion equipment. These include inverters in railway traction systems and for DC power transmission.

Mainly, the demand for devices offering high output, high efficiency and wide ranging output capacity is growing. Thus, in 2021, Mitsubishi Electric released two versions (3.3kV/450A and 3.3kV/600A) of its HV100 dual-type X-Series high-dielectric-strength HVIGBT module. In the near future, the forthcoming HV100 dual-type X-Series module will contribute to even higher output, higher efficiency and improved system reliability for inverters used in large industrial equipment requiring high dielectric strength.

Product Features

1) Industry-leading current rating for higher output and more efficiency in inverters

The module’s current rating of 450A, unsurpassed among 4.5kV dual-type modules, helps increase the output and efficiency of inverter systems. Also, the 7th generation IGBTs adopt the CSTBTTM2 structure and the diodes adopt Relaxed Field of Cathode (RFC) technology3. Both are proprietary technologies that have been optimized to balance high withstand voltage operation and low power loss. Moreover, optimized wiring between the main P-N terminals reduces internal inductance for faster switching and lower power loss.

2) Optimized terminal layout suited to various inverter configurations and capacities

The optimized terminal layout enables parallel connection and supports various inverter configurations and capacities depending on the number of parallel connections. Also, the package structure, which arranges DC and AC main terminals in opposite poles, helps to simplify circuit design.

3) Reduced thermal resistance contributes to inverter system reliability

The integration of the insulating plate and base plate reduces thermal resistance between the junction and the case to help extend the thermal cycle life.4 The base plate’s uniform flatness and the power semiconductor chip’s heat dissipation reduce the contact thermal resistance between the case and the heat sink to further extend the thermal cycle life.5

1Compared to Si IGBT modules with dual-type HV100 packages achieving 4.5kV withstand voltage and 10.2kVrms insulation voltage, according to Mitsubishi Electric’s own research as of April 25, 2023.

2 Mitsubishi Electric’s proprietary IGBTs using the carrier accumulation effect

3 Mitsubishi Electric’s proprietary diode with optimized electron mobility on the cathode side

4 Case lifetime when temperatures changes have relatively long cycles

5 Case lifetime when temperatures changes have relatively short cycles