ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Imec Demos Lower Resistivity Conductor Films on 300mm

Leading research in nanoelectronics and digital technologies imec has provided the first experimental evidence that the resistivity of a thin conductor film on a 300mm Si wafer can be lower than that of Cu and Ru. Currently, interconnect metallization schemes use Cu and Ru.

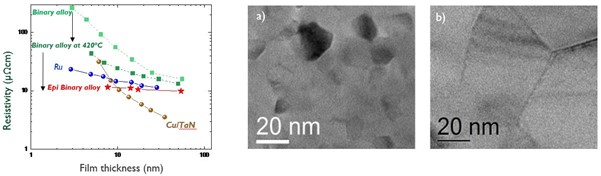

For example, a resistivity as low as 11.5µWcm measured for a NiAl binary alloy of 7.7nm thickness, obtained after grain size engineering. The results mark a milestone towards enabling low-resistive interconnect with line widths below 10nm.

There is a strong need to keep pace with the continuing device scaling. For that reason, the width of the most critical interconnect lines in state-of-the-art logic and memory chips soon approaches 10nm.

At these small dimensions, the resistivity of Cu increases dramatically, and its reliability degrades. For that reason, the interconnect community has been compelled to identify alternatives to Cu metallization. While the focus was initially on elemental metals, the search has been extended to binary and ternary ordered intermetallics initiated by imec at the 2018 IITC conference.

(Image Credit: imec)

Continued Search to Replace Cu, Ru

Imec set up a unique ab-initio-based methodology to select and rank the most promising materials. Particularly, they used the product of the bulk resistivity and the mean free path of the charge carriers (r0 x l) as one of the main figures of merit. This theoretical assessment was the starting point for further experimental work on 300mm wafers.

Zsolt Tőkei, fellow and program director of nano-interconnects at imec, said, “To better understand and model the resistivity behavior of the selected binary alloys at small dimensions, we introduce at the 2023 IEEE IITC conference an effective resistivity, which considers composition variation and the effects of order and disorder. Further analysis revealed that the resistivity of thin films of binary alloys is dominated by grain boundary scattering due to the small grain sizes inherently present in thin conductor films, whereas disorder contributes for thicker films as well.”

For the case study of stoichiometric NiAl, a resistivity as low as 11.5µWcm was measured on a 7.7nm thin film, which is 23% lower than Cu. This became possible after depositing a 50nm thick large-grain NiAl film on a Ge epi-layer at back-end-of-line (BEOL) compatible temperatures, followed by thinning experiments.

Moreover, these experiments preserve a larger grain size (45.7nm). Hence, reducing the contribution of grain boundary scattering to resistivity.

Zsolt Tőkei said, “The experimental existence of low-resistive thin conductor films on 300mm wafers motivates us to continue our search for binary and ternary alloys. At the same time, we investigate the composition control of the alloys and their integration compatibility with future metallization schemes that will likely be based on subtractive etch.”

At 2023 IEEE IITC, imec has 10 oral presentations addressing the main challenges in interconnect scaling. Besides two papers on alternative metals exploration – including one invited contribution – the papers highlight work on semi-damascene metallization, reliability, thermal impact of advanced interconnect stacks, middle-of-line metallization schemes, and more.