ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Honeywell Actuators Advance Li-Ion Battery Production

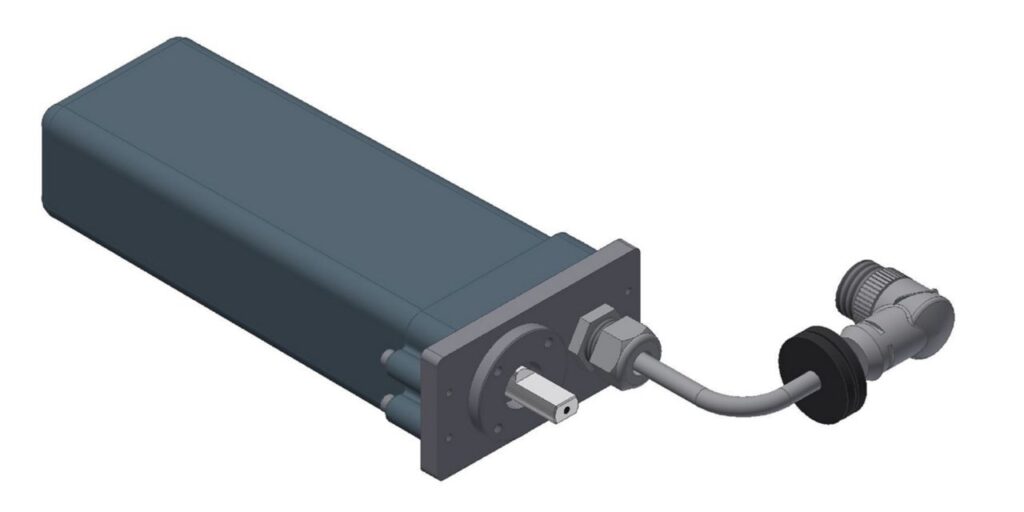

Honeywell has unveiled the ProFlow FT and ProFlow XT actuators. Particularly, they combined with online quality measurements comprise an advanced control system for the cast film, extrusion coating, and electrode coating processes in Lithium-Ion Battery manufacturing.

Designed to replace the slower thermal bolt actuators currently used by most extrusion and fluid coating processes, the ProFlow XT and FT provide unprecedented, motorized precision lip adjustment with significant quality control benefits. Moreover, the time to reach quality production from cold start is reduced from about an hour to just a few minutes, when compared to thermal bolt technology.

Faster Manufacturing ROI

Precise direct control of the die lip position achieves better steady state control as opposed to existing methods which can suffer from analog drift. For example, the benefits can achieve improved production line safety; faster startup; and higher yield via automated grade changes. In addition, it can improve product quality through reduced variations; increased productivity and more flexible production scheduling through faster process turnaround time.

“The ProFlow XT and FT actuators replace a legacy production technology that’s been used by packaging and battery manufacturers for decades,” said Juha-Pekka Jäntti, offering management lead, Honeywell Process Solutions. “The solution is not only available for new production lines, but it can be easily retrofitted to existing processes and deliver return on investment within as little as six months.”

Honeywell Process Solutions’ integrated portfolio of hardware and software solutions leverages the Industrial Internet of Things (IIoT) with Forge enterprise capabilities and can be paired with its ControlEdge™ Programmable Logic Controllers (PLC), Battery Manufacturing Excellence Platform (MXP), QCS 4.0 remote monitoring solution, and process controls to maximize operational efficiency. Hence, this integration ensures quality global project execution resources through long term local service and supports sustained benefits from initial startup.