ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

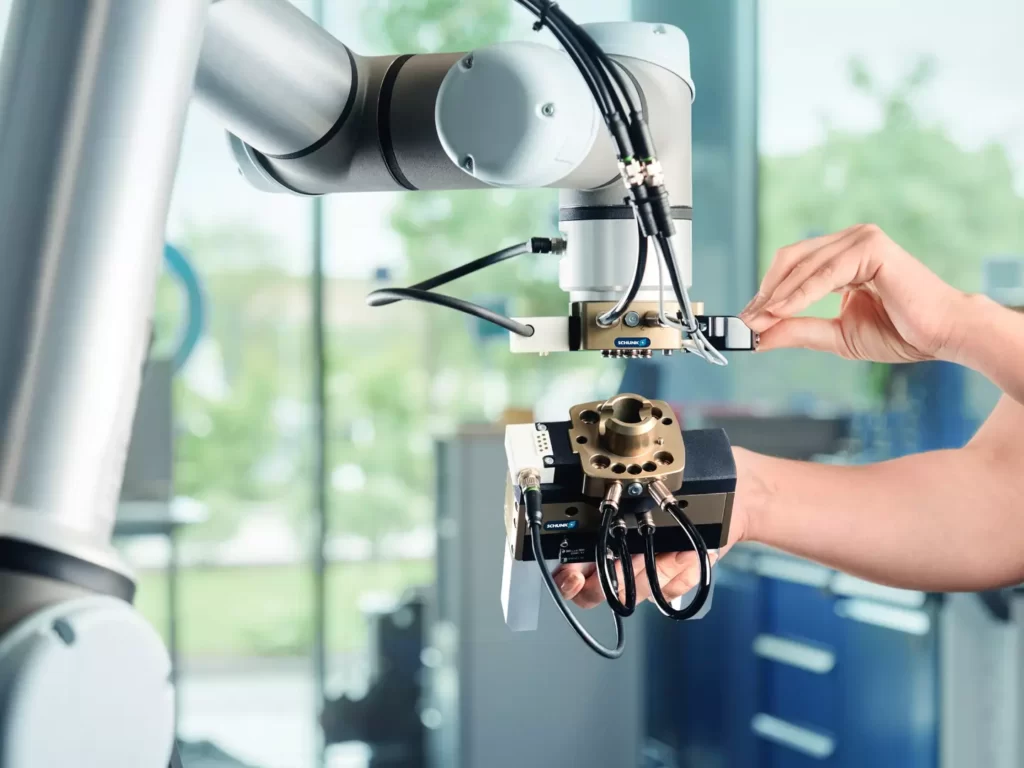

New System Speeds up Robot Tool Changeover

The new CMS manual change system from SCHUNK is the optimal addition for flexible tasks in manufacturing, handling technology, or assembly workstations. Specifically, it enables rapid, process-reliable changeover at the robot front end or also on stationary systems, like fixture construction. The manually operated system consists of a CMS-K interchangeable head and a CMS-A interchangeable adapter. Additionally, the system handles payloads of up to 58kg. Combining it with handling or machining components from the extensive SCHUNK portfolio is also possible. These range from grippers to machining tools from the R-EMENDO Series, for example for automated deburring, polishing, or filing.

The CMS is the further development of the SHS changing system, which is already an established part of the SCHUNK portfolio. Also, the CMS replaces the SHS 1:1 as it has the same height and screw-on patterns. The successor version now offers decisive optimizations in terms of operation, design, process reliability, and usage options.

Fast and Process-reliable Changing

The tried-and-tested push lever technology makes the operation of the CMS extremely simple and convenient. Locking the interchangeable head with the interchangeable adapter without the use of any additional tools is possible by hand. Innovative, integrated air feed-throughs via sealing pins with cylinder seals support manual locking. This way only minimal force is required for this process. In addition, the thrust lever has a new, cranked shape that does not conceal any of the numerous connections. This means that all system connections can now also be used radially.

A spring-loaded latching pin, which fixes the hand lever to the housing, provides more operational safety. Also, it prevents the system from opening during operation. The integrated monitoring sensor system enables inductive monitoring of interlock status and mold presence with optional sensors. Accordingly, it provides additional operating safety and a plus in process reliability. Thanks to the ISO flange pattern, mounting the CMS is possible on all common robot types without an additional adapter plate.

Wide Range of Optional Modules, End Effectors

An integrated pneumatic feed-throughs or a vacuum allows the supply of a wide variety of end effectors such as grippers or machining tools. Also, energy supply is now possible via directly bolted-on electrical, pneumatic and fluid modules, saving both space and weight. Alternatively, SCHUNK also offers a lower-price, identically constructed basic variant CMS-B without pneumatic feed-throughs.

The CMS manual change system is available in six sizes from 40 to 125. In addition to a wide range of combination and application options, users benefit from the breadth of knowledge about applications of the full-range automation supplier.