ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Flexiv Touts Revolutionary Robotic Gripper

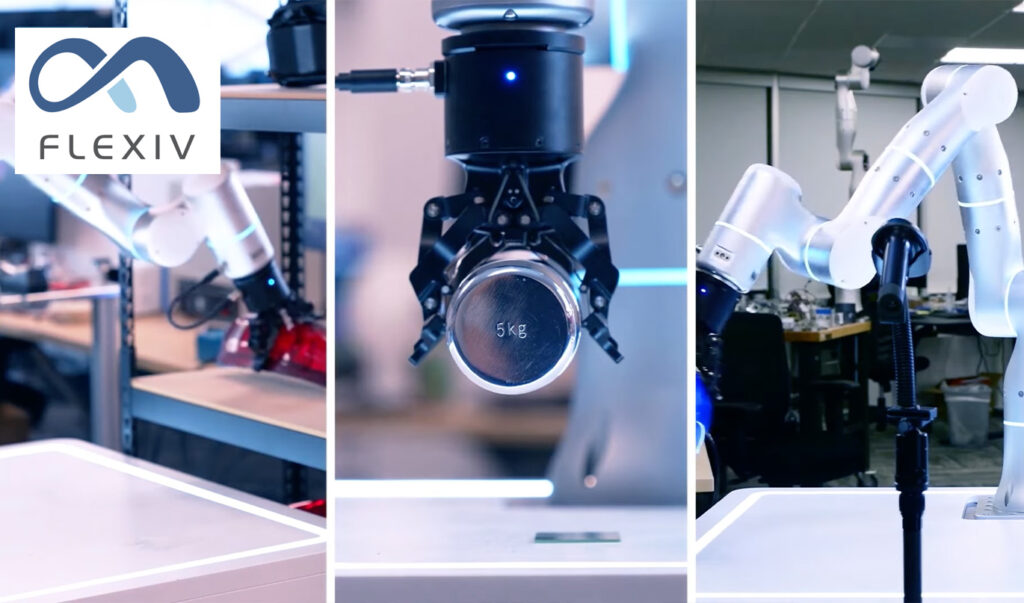

Flexiv has announced the Grav gripper, a revolutionary robotic gripper that lifts practically any item that fits within its grasp. Mainly, the gripper’s industrial-grade force control and an adhesive material based on gecko’s foot pad made this feature possible. The new robotic gripper will be available beginning Q2 2023.

The industry touts the Grav gripper as representing the next generation of robotic grippers. Specifically, it uses impactive and contigutive grasping techniques for maximum handling flexibility. These features allow the gripper to lift objects that are oddly shaped or have an uneven surface texture.

“We have been working on the Grav gripper for a while, as we wanted one which utilized the same industrial-grade force control as the Rizon line of adaptive robots.” Said Ryan Coulson, Flexiv’s Lead Mechatronics Engineer. “Not only have we successfully implemented force control, but we have also given the gripper the ability to handle traditionally difficult objects like spheres thanks to the gecko material.”

Initially, the new gripper was designed only for use with Flexiv’s Rizon Series of adaptive robots. Thus, it was created to reduce the frequency of end-of-arm tool changes. However, testing with customers who also operated traditional cobots made it clear that there was a demand for Grav beyond Flexiv’s existing customer base.

All of Flexiv’s adaptive robots employ a universal end-of-arm socket. Thus, only minimal modifications were necessary to make the new gripper compatible with a standard collaborative robot.

Coupled with the Grav’s handling flexibility is an industrial-grade force control capability. This enables the gripper to sense a resistive force in the sub-gram region.

Also, the new gripper is ideal for multiple applications. Thus, it is capable of inserting micro components, transferring delicate objects, or even machine-tending applications.