ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Samsung to Start Volume Production of QD OLEDs in 4th Q

Samsung Display will start volume production of QD OLED panels sometime in the fourth quarter turning up heat in the fast-growing large-size OLED panel market for TVs.Samsung Display said that it has been test-running its QD OLED production line at its Asan fabrication complex to begin volume production effective from sometime in the fourth quarter.

The first commercial product is scheduled to roll of the line sometime in the first half of 2022.

QD, or quantum dot OLED is a variation of true RGB OLED panels that comes stacked with self- luminous RGB OLEDs on top of a TFT backplane, a grid of thin file transistors on a glass substrate.

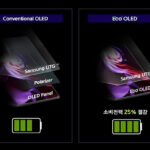

Coming built RGB QD color filter sheets, the QD OLED is stacked with a matrix of self-lighting Blue OLEDs that shed blue rays of light to create images on a display panel screen.

This QD OLED is not like LG Display’s OLED that comes deposited with a grid of white OLEDs and a RGB color filter sheet.

To stack bule OLEDs on the top of a TFT grid, Samsung adopted an ink-jet printing methodology.

Samsung’s QD-OLED line will mainly roll out 50-inch to 60-inch OLED panels using an 8th generation of 2,200mm and 2,500mm glass substrate at a monthly capacity of 30,000 substrates.

Samsung’s start of the volume production is a prelude that competition will intensify in the global OLED panel market. But also, it will help accelerate the penetration of OLED panels into TV markets, as the heated-up competition will encourage OLED panel makers to achieve big enough scale to cut down costs, enabling them to dramatically reduce panel prices to the extent that OLED and LCD panels of the same size hit a price crossover point.

Currently, OLED panels represent just a fraction of global flat screen TV market, or just 3%.

LG Display is still a sole maker of OLED panels, dominating the market. To help the market reach critical mass, LG has been struggling to create an OLED manufacturing ecosystem, inviting other display panel maker to join the efforts.