ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Unique Machine Vision Solution Boosts Robot Inspection

Israeli-based smart visual inspection company Kitov.ai has developed the K-BOX line of cost-effective machine vision systems. Specifically, the new systems combine AI, 3D imaging, and intelligent robotic planning technologies to solve manufacturing’s most demanding inspection applications. The company will introduce K-BOX at The Quality Show, Booth 812, Oct 24 to 26 in Rosemont, Illinois.

Kitov.ai’s K-BOX offers the same functionality as its Core+ solution. Mainly, the Core+ solution ships with an industrial robot. Meanwhile, K-BOX offers APIs that connect Kitov software to virtually any standard or collaborative robot on the market. This capability allows customers to add advanced visual inspection capabilities to their existing robotic solutions. Moreover, customers can choose the brand and the size of the robot according to their needs.

“K-BOX is part of Kitov.ai’s efforts to make powerful, deep-learning machine vision software available to every customer segment. It focuses on the capabilities of integrated software rather than dedicated robot software,” said Aviel First, CEO. “With K-BOX, our customers can field hybrid machine vision systems without having to adapt to robotic platforms that may not be part of their in-house robotic specifications or expertise.”

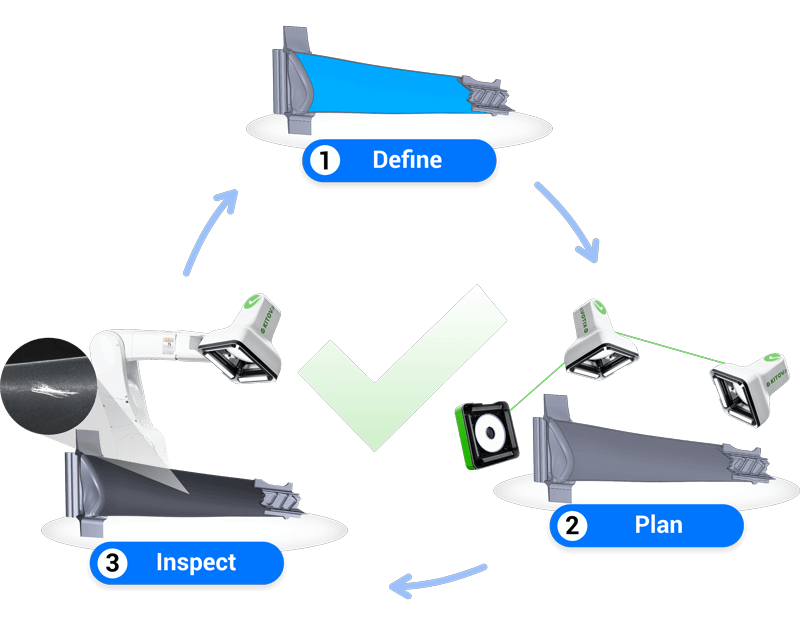

K-BOX includes Kitov’s optical head as well as a processing unit that runs the Kitov Smart Planner software. The software capabilities cover 2D and 3D machine vision, AI, and deep learning.

The Smart Planner software also incorporates the award-winning CAD2SCAN, which uses CAD files to define and plan the inspection for target parts automatically and supports the new QIF (Quality Information Framework) ISO standard. Furthermore, Kitov.ai’s Smart Planner software integrates “semantic detectors,” custom algorithms designed for specific tasks such as comprehensive screw or fastener inspection, labels, and other common assignments.

K-BOX joins Kitov.ai’s Core product line for automated visual inspection, including Kitov-Core, Kitov Core+, and Kitov-Inline.

Specifically, Kitov.ai’s CAD2SCAN won the coveted VISION award during Stuttgart’s VISION conference last year. CAD2SCAN allows quality managers to define their inspection requirements directly on the part CAD model, simply and intuitively, saving weeks or even months compared to defining such inspection programs manually.

Kitov.ai innovative visual inspection systems are deployed into various market inspection applications, including high-end electronics, automotive, defense, aerospace, and medical devices.