ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Kassow Robots Builds up Presence in U.S. Automation Market

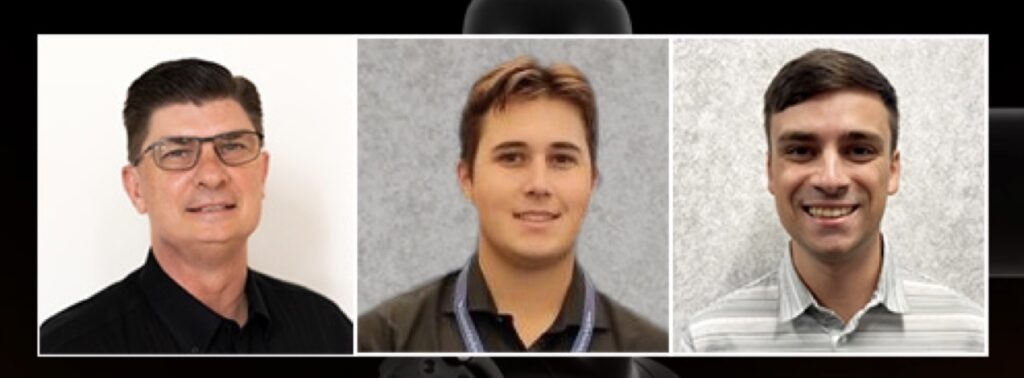

Danish company, Kassow Robots, a developer of 7-axis industrial cobots, has established a U.S. team focused on sales and support. The company’s cobot solutions suit machine tending, material handling, dispensing, and various other applications. Regional Channel Partner Managers Jim Adamski and Collin Ayres, and Technical Support Engineer Chris Hapsias will support Kassow Robots’ sales partners, system integrators, and distributors in the United States.

Kassow Robots is part of Bosch Rexroth, which has been its majority owner since 2022.

“This team will allow us to work closely with our system integrators and distributors in the United States. They will also extend our reach to new sales partners and markets,” said Dieter Pletscher, Global Sales Manager at Kassow Robots.

Jim Adamski is focused on working with the U.S. partner network east of the Mississippi River and in Iowa. He joined the Kassow Robots team earlier this year and has previous experience with Bosch Rexroth. Additionally, he has been in the factory automation industry for more than 30 years. Adamski looks forward to helping U.S. companies automate their operations efficiently and manage labor challenges. “Kassow Robots has a great lineup of 7-axis robots that are easy to set up and program,” Adamski said. “There is a vast array of potential applications, such as machine tending, welding, dispensing, and palletizing, that these cobots are equipped to handle because of their flexibility.”

Meanwhile, Collin Ayres recently joined the Kassow Robots team after receiving his mechanical engineering degree from the University of Nebraska, Lincoln. As Regional Channel Partner Manager, he focuses on helping Kassow Robots expand its presence in North America. He also supports sales partners in the western part of the U.S. “It’s an exciting time to be working in automation. I’ve enjoyed seeing users’ response to interacting with the Kassow Robots cobots at events over the past several months,” Ayres said. “The 7-axis lightweight robots suit industrial use and enable automation for operations even in the most confined spaces.”

Finally, the latest addition to the U.S. team is technical support engineer Chris Hapsias. He is responsible for providing technical support and training for Kassow Robots’ U.S. distributor network. He brings four years of factory automation experience, specifically in the autonomous mobile robot (AMR) space. “The added range of motion the 7th axis provides for the KR series robots is impressive,” Hapsias said. “They are user-friendly. They have an intuitive tablet-based user interface that allows beginners to program these cobots with little training and robotics pros to dive deeper to program complex operations.”

Kassow Robots’ 7-axis lightweight cobots offer small footprints and increased maneuverability. The unique 7th axis, or “wrist joint,” enables continuous dispensing, welding, and material removal applications. It does this regardless of access angle and without the need to reorient the arm. The cobots are easy to program and operate after a short introduction. This allows SMEs without robotics specialists to implement automation cost-effectively and independently.