ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Toyoda Gosei Increases Capacity of Mexico Facility

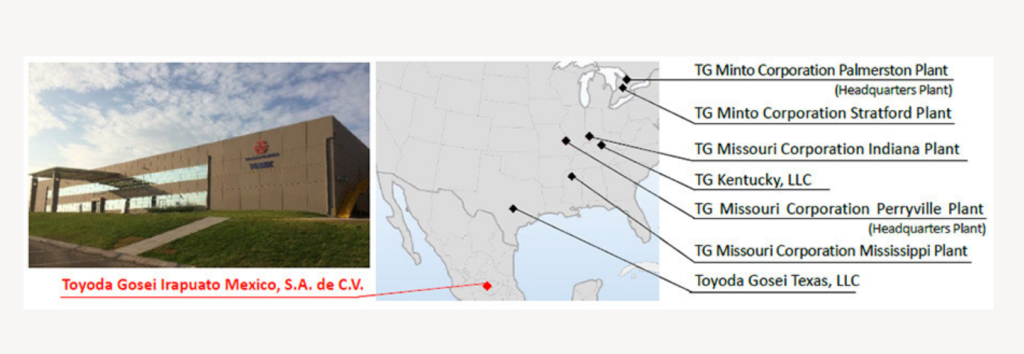

Toyoda Gosei Co., Ltd. has increased the production capacity of Toyoda Gosei Irapuato Mexico, S.A. de C.V., one of its production subsidiaries in Mexico. Accordingly, the company aims to strengthen its production network for automotive products in the key North American market.

The company expanded the manufacturing facility. Thus, it introduced new production equipment to meet the growing demand for large painted products. This includes rear spoilers and bumper peripheral parts.

Advanced Facilities for Automotive Parts

Toyoda Gosei started the production of these parts in December 2023. In addition, the plant upgrade is an opportunity to introduce the latest energy-saving machinery. Particularly, molding machines that cut CO2 emissions by about 40% compared with previous machines. For that reason, the company can foster more environmentally friendly manufacturing.

Toyoda Gosei has been expanding the production capacities of some of its global facilities to meet growing demands. Especially, for products related to the automotive fields.

Early this year, the company enhanced the production capacity of its facility in Brazil, the GDBR Industria e Comercio de Componentes Quimicos e de Borracha Ltda. (GDBR). Accordingly, the plan aims to keep pace with the growing sales of airbags and other safety systems in South America.

Also, Toyoda Gosei also enhanced the capacity of its Toyoda Gosei Minda India Pvt. Ltd. Particularly, the capacity expansion of its Neemrana Plant aims to meet the growing demand for airbags as safety regulations become stricter in India.

On the other hand, Toyoda Gosei has started the operations of its new plant in Guangdong Province in China last November. Particularly, the plant will strengthen the company’s capacity for its automotive safety systems. As a smart factory adopting Toyoda Gosei’s latest production technology, the new plant will pursue efficient and environmentally-friendly manufacturing. Here, the company has been implementing autonomy in product assembly, transport, and other areas, and electrification of facilities.