ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Festo Portfolio Drives Intralogistics Motion Automation

Festo introduces its comprehensive selection of electric and pneumatic components for intralogistics motion automation. Specifically, this includes pushing and sorting, gripping and picking, and lifting and conveying works.

“No material handling competitor comes close to Festo’s breadth of electric and pneumatic components and systems, robust supply chain, and ease of commissioning systems into the top control architectures,” said Frank Vanderpool, Industry Segment Manager, Logistics Systems, Festo. “Festo’s one-stop-shop brings intralogistics solutions to market faster, with less engineering overhead.”

7th-axis Solution for Bin Picking

New distribution centers and existing facilities deploy robotic systems. They lower labor, increase throughput, and reduce the risk of error when moving their products internally. Seventh-axis robots are robots on an electromechanical linear actuator moving horizontally, vertically, or both. Mainly, they offer productivity and cost advantages in picking and placing and unloading and loading applications.

Adding a linear rail extends the reach of a six-axis robot. Moving the robot closer to the payload allows smaller six-axis robots to be used for the application. Because robots are sized by reach – the longer the reach the larger the unit – 7th-axis solutions using smaller robots lower acquisition cost. Smaller also means a more compact footprint. Specifically, seventh-axis systems can accommodate both six-axis robots and cobots.

In a new dynamic solution of 7-axis robotics in a simulation of efficient bin picking, Festo integrates cobots from two different manufacturers. Festo’s solutions are robot agnostic and system integrators can easily choose the cobot, or robot, best for the end user.

Besides a 7th-axis used for linear transfer, the Festo Motion Control Package (FMCP) panel controls turntables, automatic storage systems, conveyors, and transfer tables. Specifically, the FMCP solution provides extra space within the panel for future expansion and brackets for wall mounting, which reduces footprint.

The company’s solution for bin-picking includes the adaptive shape gripper DHEF, the adaptive finger gripper DHAS, and vacuum gripping solutions.

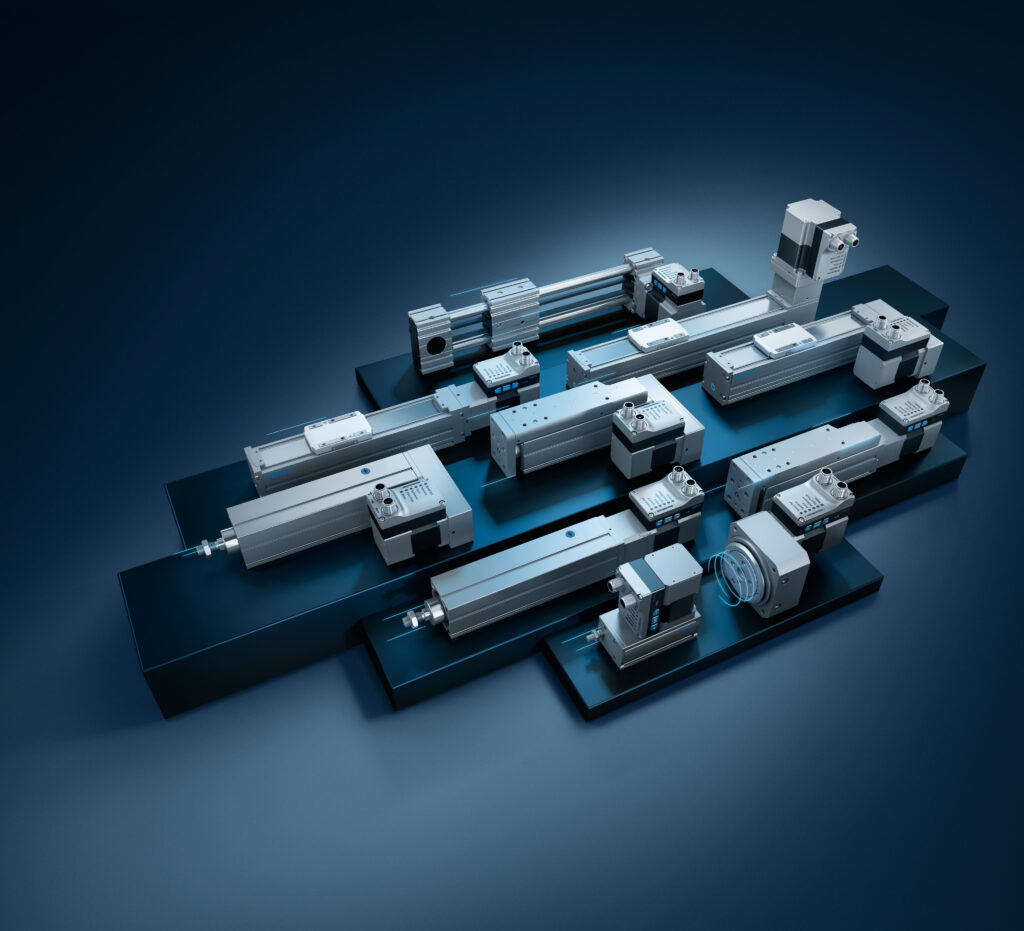

Moreover, Festo’s EGC belt-driven linear axes are ideal for 7th-axis solutions and can come equipped with a robot/cobot mounting plate. The EGC has an energy chain for cable management and servo motors optimized for performance. Meanwhile, standard EGC axes are available in lengths of up to 8.5m with up to 10m axes available on request. Festo offers a host of other linear actuators, including the ELGC ball screw actuator.

Pushing and Sorting

Additionally, the Festo Simplified Motion Series (SMS) electric axes are comparable to pneumatics in cost and ease of installation. However, they deliver the advantages of electrics. SMS axes offer lower energy consumption than pneumatics and generate a wealth of data. Also, SMS axes deliver two-position motion through onboard controls. Through IO-Link, a standard SMS feature, these axes can be programmed for infinitely variable positioning for flexible pushing and sorting.

For applications where pneumatics is the optimum cost/performance solution, Festo provides its DFSP pneumatic stopper cylinder, the DSNU ISO standard round-body cylinder with self-adjusting end position cushioning, and the compact, double-acting ADN for fixed or self-adjusting cushioning.

Lifting

The rugged ELGA and ELGC actuators, EMMT-AS one-wire servo motor, and innovative multi-protocol servo drive CMMT-AS offer the ideal package for Z-axis motion. Easily add additional Festo axes and gain X and Y motion for lift and position capabilities. This solution offers low vibration and high rigidity.

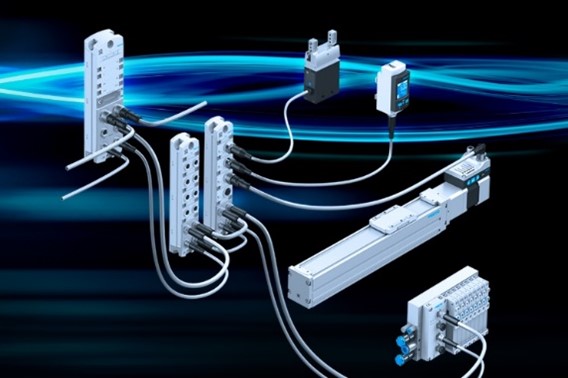

Festo’s Remote and Decentralized I/O Platform

Festo offers both the CPX-AP-A distributed I/O and CPX-AP-I decentralized I/O. Whether physically attached on-terminal or connected via cable, all components such as PLCs, valves, motors, drives, and I/O appear to the programmer to be incorporated within one smart terminal under a single IP address. Having the entire distributed and decentralized I/O topology under a single IP address significantly reduces hardware and installation costs while lowering system complexity. Since many PLCs come with a limited number of IP addresses, the Festo solution means more capabilities are possible per PLC. Festo is a leader in adopting and applying IO-Link, and customers will find IO-Link capabilities integral to the new I/O automation platform. This I/O platform is ideal for effective conveyor control.

Mechatronic Training from Festo Didactic

Festo Didactic, the training arm of Festo, has developed the Festo Learning Experience, Festo LX, a digital learning portal. Festo LX provides training module access where and when it is needed and makes it easy to create individual learning experiences for trainers and trainees.

Visit the intralogistics page on the Festo website for additional details. For more information on the advantages of working within the Festo ecosystem of less engineering overhead, fast time to market, seamless connectivity, and high-quality components, visit www.festo.com.

-19 March 2024 –