ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Nihon Almit Levels up Quality Standard of Solder Products

In expanding its solder business, Nihon Almit Co., Ltd. offers distinctive solder products that meet the “boost up almit” standard. Boost up almit standard is a new concept in which its solder product development evolves.

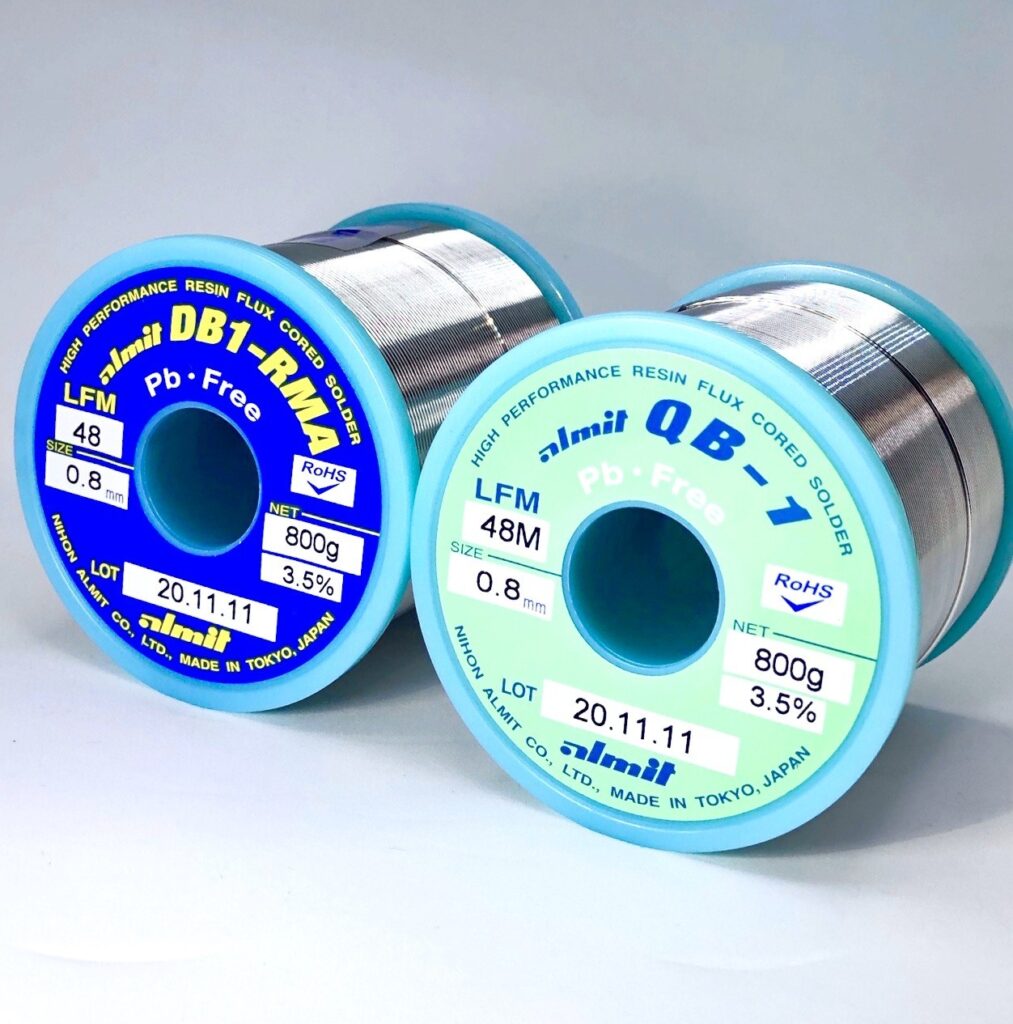

Nihon Almit released in Nov. 2020 the DB1-RMA LFM-48 (flux name+ alloy name) resin flux cored solder wire for through hole soldering. DB1-RMA LFM-48 adopts the newly developed Dual Boost technology and is the first product that complies with “boost up almit” standard.

This spring, the company released the QB-1 LFM-48M (flux name+ alloy name) resin flux cored solder as the second product under the standard. It adopts the newly developed Quick Boost technology, which exhibits quick effect to instantaneously bring out active force of the flux to its peak.

Dual Boost Technology

The Dual Boost technology used in DB1-RMA LFM-48 combines fast- and slow-acting active ingredients to promote wetting in two phases. The newly developed activator has enabled generation of activity in two phases even in solders with low halogen content of JIS-AA Grade. In Boost 1, fast-acting activator works to promote initial wetting. In Boost 2, slow-acting activator promotes the wetting of through holes, producing anti-bridge effect. This technology has significantly improved solderability to through holes of printed circuit boards (PCBs) with large heat capacities and oxidized PCBs after reflow soldering. At the same time, it reduced soldering time.

Quick Boost Technology

QB-1 LFM-48M has reduced working hours whether manual or using automatic machines as the solder wet and spread quickly. As conventional solders were slow in the initial wetting, they tend to generate a solder pool at the iron tip that causes flux to explode. QB-1 rarely generates a solder pool thanks to the Quick Boost technology. Flux splattering and generation of solder balls also occur less.

Makoto Sawamura, Chief Executive Officer, Nihon Almit Co., Ltd., says, “Customers require solder products that enable improvement of productivity through the reduction of soldering time. This leads to reduction of costs and provides basic bonding quality. The new highly acclaimed products have satisfied these requirements.”

“Sales got off to a fast start compared to new products released in the past. Some customers reduced in half soldering time of multipin through hole soldering. Some of our new customers adopted the new products,” he said.

Broad demand for both DB1-RMA and QB-1 is seen in PCBs for automotive and industrial equipment, as well as for general PCBs. Inquiries for products for application by soldering robots have also been increasing.

Broad Array of Solder Products

Sawamura, explains the recent landscape of the solder market, “As the manufacturing industry recovers from the COVID-19 pandemic, the demand for products has been increasing. Demand has been steadily increasing in China and Europe, as well as in Japan. Activities have also got back to normal in Southeast Asia, where lockdown continued.” Sawamura also noted the company’s positive financial results at the end of the fiscal year in September.

To increase sales, Nihon Almit also meets diversifying market needs for solder products by implementing finely tuned product strategy. The company’s extensive portfolio includes the newly developed LFM-48W MR-NH solder paste, which features ultralow viscosity and excellent printability free from print and preheat sagging; the GTH-RAMA (flux RMA type) high-performance resin flux cored solder for PCBs for automotive equipment; the LFM-48 SDK and LFM-48 MJD syringed solder pastes for dispensers, for which demand has been increasing; and the LFM-H Series solder bars containing antioxidant for dip soldering, which has recently been increasing.