ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

LTCC Material for 5G Highlights Low Loss

Nippon Electric Glass Co., Ltd. continuously develops low-temperature co-fired ceramic (LTCC) materials with low loss tangent. These materials are suitable for parts and devices used for 5G communication. Through this endeavor, it dramatically improved the characteristics of its product lineup, which are the highest in the industry.

5G communication technology enables high-speed, large-capacity, low-delay communication and multiple simultaneous connection. High frequencies of 28 to 40GHz, which are known as millimeter waves, are used for this communication.

Efficient Communication in mmWave

Various LTCC substrates are used in parts and devices that process the signals (e.g., circuit boards, filters). For these parts and devices, the higher the frequency and the greater the loss tangent, the greater the signal attenuation. Suppressing signal attenuation and attaining low signal loss realizes more efficient communication in millimeter waves. LTCC substrates made from materials with a low loss tangent are used for this purpose.

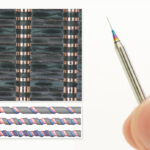

LTCC is a composite material of glass powder and ceramic powder, and can be fired at low temperatures of 1000°C or less. Complex high-frequency components can be manufactured by co-firing this material and a silver conductor with high electric conductivity to create a multilayer structure.

Three Types of LTCC Material

The company has solved market issues for three types of LTCC materials released in 2020. They are high CTE, high mechanical strength, and low dielectric constant LTCC characterized by low loss tangent.

For the high CTE type, the loss tangent has significantly exceeded the target of 0.0010 or less. It achieves low loss tangent of 0.0003, the lowest in the industry and 75 percent lower than the current product.

For the high mechanical strength type, the characteristics have been improved to attain loss tangent of 0.0006, which is 57 percent lower than the current product.

For the low dielectric constant type, the strength, which posed an issue toward commercialization, has been improved by about 15 percent from 130 to 150MPa. This is the highest strength in the industry as a material with a dielectric constant of less than 4.

The company manufactures and sells special glass products for various electronic devices. With these products, the company responds to new market needs and contributes to improve the performance of next-generation communication equipment.