ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Sensor Offers Millers Significant Cost Savings

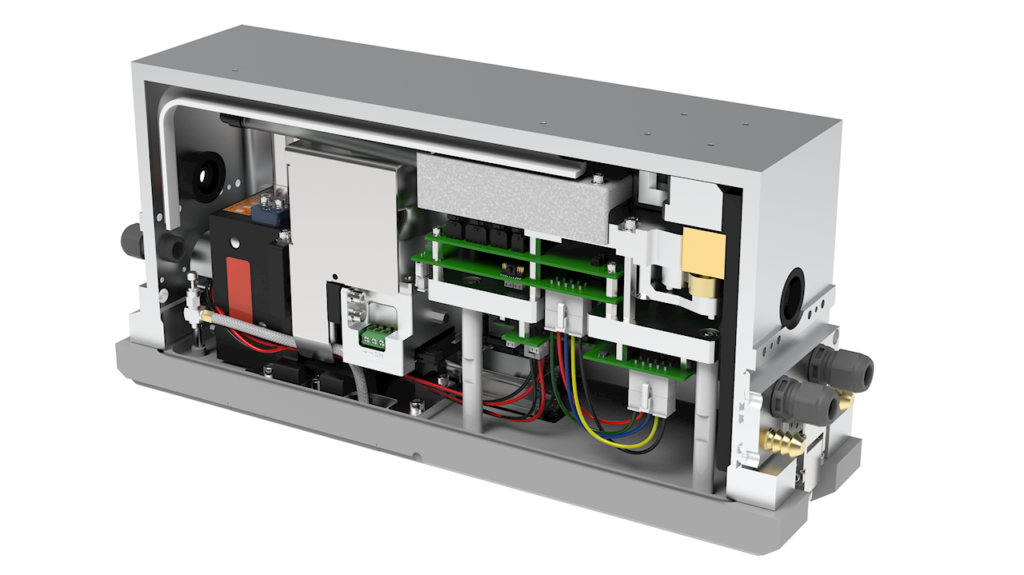

ABB has released its High-Performance Infrared-Reflection (HPIR-R) moisture sensor, which provides fast and precise moisture monitoring. Specifically, the sensor delivers precise and high-resolution measurement. In addition, it can take 5,000 measurements per second, enabling mills to increase throughput while reducing operating costs.

This advanced, patented technology will help pulp, paper, and board manufacturers to always know the precise moisture levels. Therefore, this will give them confidence to raise moisture targets and improve their CD profiles. Eventually, this will contribute to enhancing end-product quality with fewer rejects as a result.

Being able to measure and control the moisture levels as the sheet moves through the paper machine is critical to reducing energy requirements. This leads to optimized drying, decreased steam usage, significant energy savings in dryer sections, and reduced carbon emissions. In fact, according to ABB, changing the steam pressure to create a moisture change of just 1 percent can equate to US$400,000 in energy savings.

The small spot of infrared energy used in the sensor provides excellent streak resolution and accurate edge-to-edge sheet measurement, even in the most difficult environments. Measurement while scanning is continuous, with no beam chopping or filter wheels ensuring optimum signal-to-noise ratio and maximum measurement rate.

High Frequency Measurements

The design of ABB’s new HPIR-R moisture measurement, which also has a built-in sheet temperature sensor, is fully air-cooled and field repairable. That is, coupled with its insensitivity to dust and disturbances enables high uptime and lower total cost of ownership than similar solutions.

“Unlike competitive offerings, ABB’s HPIR-R moisture sensor provides the highest frequency measurements possible, which helps customers improve quality, reduce downtime, decrease costs and increase yields,” said Andy Broomfield, Product Line Manager at ABB.

While it can be placed in any location, the highest impact application for this reflection moisture sensor is before a size press, where better precision and accuracy let you raise the moisture target, giving optimized starch/sizing pickup and reduced drying energy demand. This also applies to pre-coat locations.

Another high-value application is placing it after the wet press section, enabling operators to adjust press loadings to improve the moisture profile and increase sheet dryness going into the dryers. In addition to energy savings, this also gives higher sheet strength in that sensitive area of the machine, meaning improved runnability and sheet break recovery.

Part of the ABB Ability Quality Management System, the sensor is fully digital with high-speed measurements provided alongside a rich set of diagnostic data which is ideal for analytics to inform on-site or corporate-level decision-making. It is applicable for all network platform types and can be used to measure publication grades, graphic papers, board, tissue, packaging, specialist, and recycled grades.