ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Industrial Robot Poises for Continuous Growth

The industrial robot market has been expanding and is shaping up to becoming a huge market. This is backed by growing production automation and decrease in working population.

In the future, the dwindling of birthrate and aging population will further accelerate in Japan and China. Thus, the reduction of working population is becoming a serious problem for the manufacturing industry. Against this backdrop, the momentum to use industrial robots for manufacturing has been building up.

Industrial Robot Classification

Industrial robots are broadly classified into SCARA robots with an articulated structure with emphasis on movements in the horizontal direction; vertically articulated robots with emphasis on vertical movements; parallel link robots that move like human’s hands; and orthogonal robots that are also called gantry robots and are constructed mainly with the orthogonal coordinate axial structure. Meanwhile, collaborative robots, a new classification of robots, are designed to work with people.

Safety Requirements of Robots

Installation of safety fence is required by the Industrial Safety and Health Act and the Ordinance on Industrial Safety and Health stipulated by Japan’s Ministry of Health, Labor and Welfare in order to secure safety of industrial robots. Previous regulations required that industrial robots with high power (80W or higher) be surrounded by a safety fence and isolated from the working space of people. However, regulations were relaxed in Dec. 2013.

New regulations allow industrial robots with 80W or higher power to cooperatively work with people. This applies to robots equipped with a measure to decelerate or automatically stop by detecting the movements of the worker using human detecting sensor, Moreover, attaching the robot should not involve any risk of endangering the worker.

Since the easing of regulations, industrial robot manufacturers have successively commercialized robots that can be used without a safety fence as collaborative robots. Nowadays, collaborative robots are at the center of demand for robots.

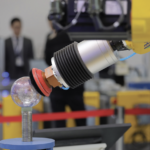

Peripheral Equipment Growth

As industrial robots are widely used, the development of peripheral equipment that supports various workpieces has also been accelerating. Main bodies are key business areas of robots. However, robot hands and grippers to be attached to the robot arm as well as robot wears have been attracting attention as new robot business fields. These also include autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) used for transfer in factories.

Versatility of Industrial Robots

Industrial robots have higher general versatility compared with specialized machines. By rewriting programs, they can be used for the manufacture of many product items. This is a major advantage of industrial robots. However, to operate an industrial robot, programming work called teaching is necessary. Teaching requires specialized technology and experience and involves workers’ training cost and time.

Hence, recently, the development of technologies that assist teaching and enable automation has been advancing. Specifically, a technology to identify product models using image processing of the robot vision system and to automatically call up an optimum program embedded with artificial intelligence (AI) function is underway. Ease of teaching has propelled the expansion of the industrial robot market.

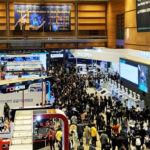

Robot Exhibition in Tokyo

The 2022 International Robot Exhibition (iREX2022), one of the largest robotics trade shows, was held in Tokyo from March 9 to 12. At the event, exhibitors showcased state-of-the-art robots, ranging from industrial robots to service robots.

Leading-edge systems for industrial robots and related equipment were on show coupled with demonstrations.

Also displayed were many service robots that play an active part during the COVID-19 pandemic.

Major robot manufacturers

On the venue, Yaskawa Electric Corporation, NACHI-FUJIKOSHI CORP., FANUC Corporation, Mitsubishi Electric Corporation, and Kawasaki Heavy Industries, Ltd. set up large booths where they demonstrated new series of collaborative robots, factory automation (FA) products, and linkage solutions. Meanwhile, Japan Aviation Electronics Industry, Ltd. and Hirose Electric Co., Ltd. introduced latest connectors for robots.

Exhibits of industrial robots and service robots developed in collaboration with local municipalities, universities, and research institutions were also eye-catching.

The Fukushima Innovation Coast Promotion Organization promotes FUKUSHIMA INNOVATION COAST FRAMEWORK, which is a national project. It set up Fukushima Robot Test Field (RTF) Pavilion on the venue and introduced companies developing robots and drones with their bases in the RTF facilities.