ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Industrial Robots Capture Attention at Equipment Show

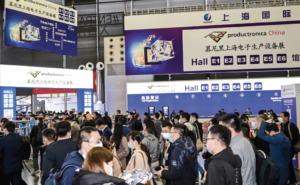

The renewed agility of the Chinese manufacturing industry was clearly shown at productronica China 2021 which drew 77,000 visitors on site, building up a new demand momentum for the coming months.

productronica China 2021 is an exhibition of manufacturing equipment held in March in Shanghai and organized by Messe München GmbH.

Recovered Market as Backdrop

Following the government’s success in combating the novel coronavirus, China’s manufacturing industry recovered from June 2020. At present, production activities at electronics-related industries have surpassed the pre-pandemic level, as well as those for domestic demand. This is visible particularly in electronics for electric vehicles (EVs), fifth-generation (5G) communications, and production automation. The manufacturing equipment market, including mounters, has also been expanding.

Traditionally held in March every year, productronica China was pushed back to July in 2020 due to the pandemic. This year, the event drew 735 companies from around the world. Japanese makers include Kaga Electronics Co., Ltd., Shimadzu Corp., JUKI Corporation, Shin-Etsu Chemical Co., Ltd., Tokyo Weld Co., Ltd., Nihon Superior Co., Ltd., HAKKO Corporation, Panasonic Corporation, FUJI Corporation, FANUC Corporation, Musashi Engineering Inc., and Yamaha Motor Co., Ltd. showcased their products and technologies through local companies.

Demand for smart factories and intelligent systems has been increasing in China’s electronics-related manufacturing industry. Against this backdrop, FUJI, Yamaha Motor, JUKI, and Panasonic proposed leading-edge technology solutions designed for smart factories.

FUJI promoted FUJI Smart Factory with NXTR next-generation mounter at the core. Yamaha Motor touted One-Stop Solution made possible by its full line of surface mount technology (SMT) machines, including mounters, ultrahigh-speed high-resolution high-end three-dimensional automated optical inspection (AOI) systems, and components warehouses. Yamaha’s distributors, including MASS CO., LTD. also participated in the event.

JUKI exhibited the automation of the mounting line, highlighting the RX-7R mounter, as well as mounting pre- and post-processes. Panasonic also introduced smart factory mainly using panels. Tokyo Weld exhibited the TWA-4101 AOI system, which is its mainstay product.

Other key exhibitors include Germany-based Kurtz Ersa and YXLON, which featured reproduction of a manufacturing process in the smart factory demonstration area.

Flurry of Robot Manufacturers

On the back of the trend toward the automation of production, exhibits of industrial robots were noticeable. Aside from Japan’s FANUC Corporation, and major overseas manufacturers, such as Taiwan’s Hiwin Technologies Corp., many major local robot manufacturers, including Standard Robots Co., Ltd. in Shenzhen, ForwardX Robotics Inc. in Beijing, and Siasun Robot & Automation Co. in Shanghai showcased their robots.

Standard Robots is a manufacturer of transfer robots, and its control algorithm for autonomous mobile robots (AMRs) is said to be among the world’s top level. ForwardX Robotics manufactures collaborative AMRs. SIASUN is an all-around manufacturer of robots, which belongs to Chinese Academy of Sciences, the leading science and technology organization in China. On the event venue, many manufacturers were proposing their robots as automation systems through collaboration with Chinese or overseas manufacturing equipment manufacturers.

Electronic chemical materials companies present include Shin-Etsu Chemical and many German companies, including Henkel AG & Co. KGaA, Panacol-Elosol GmbH, Wevo-Chemie GmbH, and DELO Industrial Adhesives Inc. They promoted new dispensing and chemical materials technologies and products targeting automotive and medical industries, and announced many innovative solutions.

Shin-Etsu Chemical introduced its wide range of businesses, including Zhejiang Shin-Etsu High-Tech Chemical Co., Ltd., which manufactures and sells silicone products; Suzhou Shin-Etsu Polymer Co., Ltd., which manufactures and processes keypads, silicone rubber molding products, and carrier tapes; and Shin-Etsu Technology (Suzhou) Co., Ltd., which manufactures and sells voice-coil motors (VCMs).