ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Generation Robot Unlocks Optimal Automation

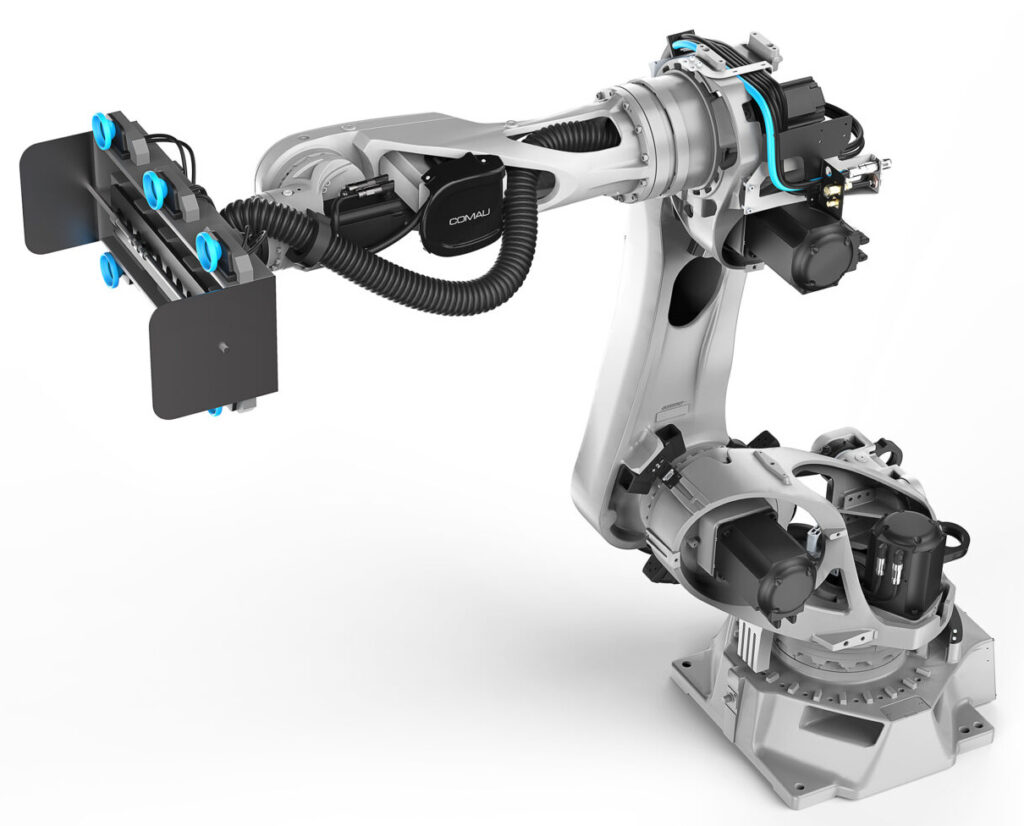

Comau has been expanding its product portfolio with the release of the new N-220-2.7 (N-220) 220kg-payload robot. N-220 features a modular set up, direct kinematics, absolute calibration, and enhanced algorithms. These characteristics deliver significant ease of use, straightforward integration, and faster post-installation maintenance. At the same time, they ensure precision, flexibility, repeatability, and minimum backlash.

The new robot is manufactured via a fully automated production line directly in Comau’s Innovation Center of Advanced Robotics in Turin, Italy. With this, its increased generation robot offers new levels of quality, supply chain flexibility, and cost-effective operation.

Target Markets

Since the 1970s, Comau has built an unrivaled experience in robotics applications in the automotive industry. The introduction of the more capable, flexible and effective N-220 will consolidate Comau’s position in automotive while enabling the expansion in high-growth industry segments, including metal, food & beverages, fulfillment and plastic & chemicals.

“Based on the 2021 IFR (International Federation of Robotics) Report, we expect 160-220kg payload articulated robots to represent an estimated 30 percent of the total installed market. This is comprised of 250,000-300,000 units in 2022 with a potential compound annual growth rate (CAGR) from 2022-2026 of 2 percent,” said Nicole Clement, Chief Marketing Officer.

“This new generation robot generates clear customer advantages thanks to its innovative design and state-of-the-art advanced robotics technology. This allows us to better target new, high-growth industry segments beyond traditional manufacturing with the aim of enhancing cost-effective automation for businesses of all sizes.”

Design Specifics

Innovative structure

Comau’s new N-220 industrial robot features an innovative architectural approach based on progressive modularity, component reduction, advanced motors and APC drivers. With its wide working area and Performance Level D cartesian safety features, the high payload (220kg) robot is perfect for a vast range of industries, including automotive, food & beverage, fulfillment and logistics, among others.

The N-220 robot has a hollow forearm and an integrated application dressing. It also benefits from its use of direct kinematics, absolute calibration and evolved motion algorithms. All of which combine to deliver best-in-class repeatability and precision. Furthermore, the robot comes fitted with integrated forklift adapters. It has optional high-torque washers for automatic anchoring base fixing, easier relocation and faster installation.

Easy to install, use and maintain

The first of a new generation of 6-axis articulated robots, N-220 addresses the specific market need for cost-effective and easy to integrate robotics that also deliver high-speed industrial performance. The holistic design and modular architecture of N-220 also make it easier to install, use and maintain.

It is manufactured at the Comau headquarters in Grugliasco (Torino), Italy using a state-of-the-art robotic assembly line. The assembly line reliably automates assembly, spot welding, packaging and material handling operations. In addition it delivers continuous process applications, such as 3D printing and gluing.

Simplified, modular architecture

Comau’s e-Motion software algorithm improves cycle time, motion quality, and path control.

Axis 2 uses a nitrogen balancing system and axis 3 uses larger stroke-ends. Thus, the N-220 robot enjoys increased agility and a wide backward working area ideal for bending and handling applications. As N-220 uses only two motor sizes and a single oil type, replacing a faulty motor becomes quick and easy.

More so, the simplified, modular architecture promotes easier overall maintenance and improved Mean Time Between Failure (MTBF). This is due to a 50 percent reduction of robot componentry.

Speech-based coding language

Recognizing that the integration speed has a direct impact on production potential, N220 implements Nodal speech-based coding language for open, easy programming. The easy dressing solution is made of two, separate, flexible harnesses (robot and application power supply), which facilitate an easy and fast upgrade, or replacement. Similarly, the direct assembly between the motor and gearbox simplifies mechanical transmissions and minimizes power loss and backlash; thus increasing efficiency and reducing consumption.

In short, everything has been designed to maximize performance, durability, safety, maintainability. and ease of use.

“Comau has leveraged its long-standing experience in industrial robotics to respond to the increasing need for new-generation automation that is also cost-effective and easy to use,” said Pietro Ottavis, Chief Technology Officer. “It’s the right product at the right time.”