ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Omron Adds New Functions to Simulation Software

OMRON Corporation has expanded its Sysmac Studio 3D Simulation to add the offline teaching functions. To illustrate, the simulation software works for Robotics Integrated Controller, which integrates and controls robots and control devices like vision, servo, and safety. These are critical for production equipment.

Manufacturing environments face challenges of increasing the number and complexity of inspection items prior to shipment. Particularly, this requires a lot of time.

However, while plants pursue automation at an advance stage, automation of inspection for complex products has been slow. This is because it often relies on the experience and visual inspection of skilled technicians.

In addition, the equipment development system that relies on skilled engineers requires improvement because of the man-hours required to adjust the actual equipment.

Features, Additional Functions

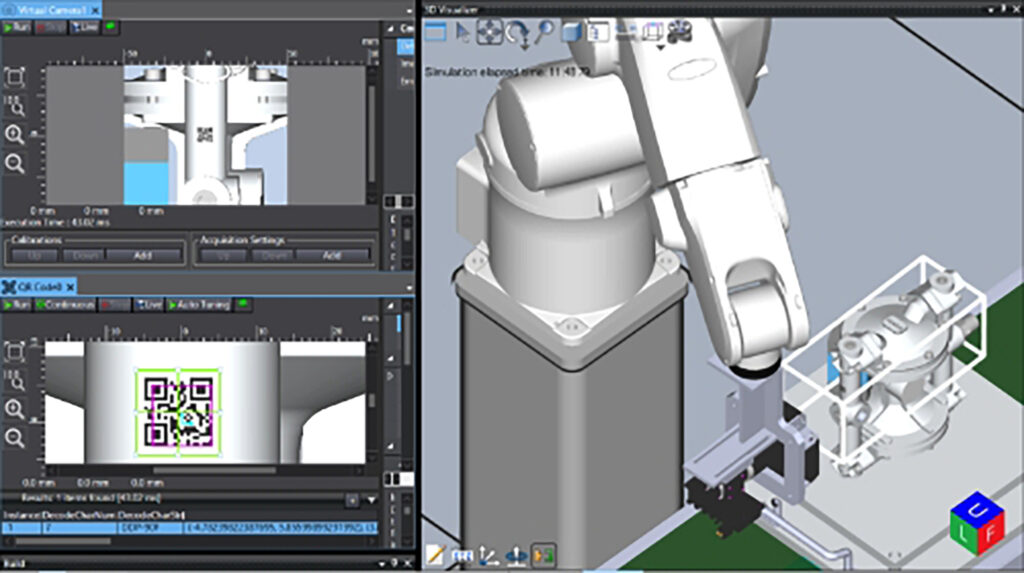

The new expanded functionality in Omron’s Sysmac Studio 3D Simulation enables virtual teaching of the motion of a camera-mounted arm robot for product inspection. For example, the teaching of an automotive part with 20 to 30 inspection points is possible in about one hour on a desk using the new function. In contrast, the conventional preparation work with the actual product or actual machine would need one day.

In addition, virtual teaching enables remote pre-preparation on a computer, even remotely. Hence, this reduces the workload of workers in manufacturing sites suffering from labor shortages. With CAD data, the inspection target can convert to 3D. It also shortens the time required to start up production of new products.

OMRON will promote DX of diversified and complex manufacturing sites through the Robotics Integrated Controller and Sysmac Studio 3D simulation to address customers’ challenge.

The added features will include three new functions using 3D simulation to shorten on-site work. First, the virtual shooting function allows the user to check the shooting status offline to determine if the camera position and angle of view are correct. Second, the snap function (position teaching) to the object can precisely specify the robot hand position and camera focus position. The system automatically calculates the coordinates of the camera, robot, and inspection workpiece to teach the robot’s moving position.

Finally, the Robot Path Planning function automatically generates paths to avoid obstacles, making robot teaching faster and easier.

Features of the Robotics Integrated Controller

The industry’s first “Robotics Integrated Controller” seamlessly integrates the control of robots and control devices with peripheral equipment. The “integration of control,” which highly automates complex tasks that could only be performed by humans, and the “integration of the construction process,” which streamlines everything from system construction to maintenance through accurate real and virtual simulation technology, provide innovative applications that incorporate robots. We will continue to develop and improve our products and services to meet the needs of our customers. OMRON will realize applications for inspection and alignment that do not stop moving and highly automated applications for craftsmanship with its various control equipment groups necessary for manufacturing and the wealth of application knowledge and technology it has cultivated over the years.

Features of Sysmac Studio 3D Simulation

Simulation software that can reproduce the entire facility digitally and easily verify its operation. Equally important, it carries same accuracy as the actual equipment by utilizing the Robotics Integrated Controller.

The software can also simulate entire facilities. These include custom robots developed in-house by the customer and equipment from partner companies. In addition to OMRON’s extensive lineup of control devices, including robots, the software can verify a wide range of entire facilities. These cover customers’ custom robots and equipment from partner companies. Hence, helping the manufacturing industry improve production capacity. Furthermore, enabling to achieve everything from facility startup to maintenance in a short period of time.