ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

KUKA iiQoT Software Optimizes Entire Robot Fleet

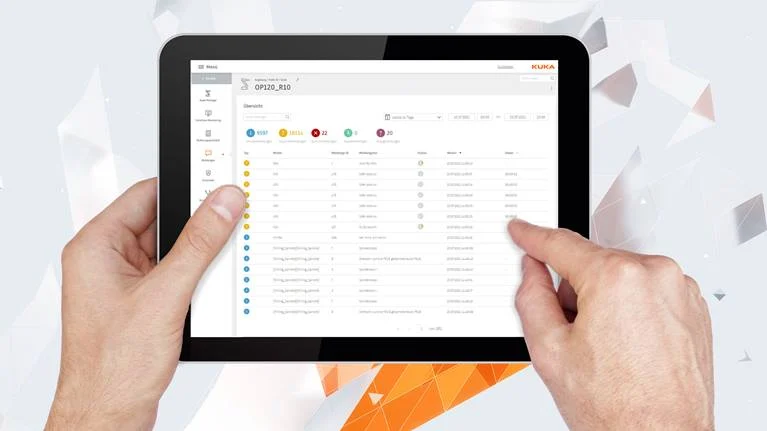

The new KUKA iiQoT platform provides important condition data for the entire robot fleet in real time. From the end of 2021, the software will initially be available as a cloud solution. It aims to make the remote monitoring of robot systems more efficient from anywhere, at any time. At the same time, this opens up new potential for troubleshooting and condition monitoring.

Smart Software Platform

The intelligent software platform KUKA iiQoT (ii of industrial intelligence, iQ for intelligence (iQ) and IIoT, or Industrial Internet of Things) provides data-based automation for companies. To achieve this, it leverages the advantages of IIoT. It bundles the condition data of a complete robot fleet transparently and clearly in one platform – from the hardware to software and on to the controller. KUKA iiQoT delivers supplementary orientation parameters, instead of simply visualizing raw data. Thus, messages are easily interpreted and faults are efficiently rectified.

Minimizes Downtime, Maximizes Operating Time

The IIoT platform clears the way for the smart factory. The most important functions include systems management, maintenance, fault detection as well as condition monitoring. If required, KUKA iiQoT users can log in to an individual robot in the selected line and cell from any location. Users can then view all parameters in real time, even accessing historical data. Several function modules work together optimally to achieve this.

Modules Work Together Optimally

“The modules provide transparency and clarity across the entire fleet,” says Dr. John Flemmer, Portfolio Manager at KUKA. “This provides you with valuable functions according to your industrial application needs.”

The ‘Fault Diagnosis’, ‘Messages’ and ‘Changelog’ modules, for example, can be used interactively for diagnostic fault-finding. After a failure, which can be informed through ‘Notifications’, users can reduce the mean time to repair and production losses. Failures can even be prevented in conjunction with ‘Condition Monitoring’.

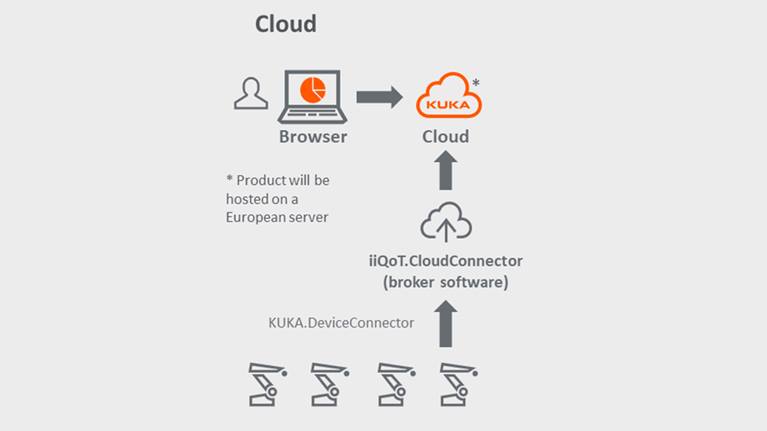

KUKA iiQoT Initially as Cloud Solution

KUKA iiQoT is suitable for small and large robot fleets. It offers maximum flexibility and scalability and is implemented in the form of Software as a Service. KUKA IoT-subsidiary Device Insight developed the cloud solution. Robots can be added to or removed from the fleet as desired. The software allows access to the latest version at all times without any hardware costs. In the future, KUKA iiQoT can support further infrastructures, enabling it to be seamlessly integrated into the customer environment.

Smart Expansions: Predictive Maintenance

The initial version will ensure customers the easiest and most affordable access to the benefits of IIoT. Smart expansions are planned so that users can benefit from further added value in the industrial environment. Interested parties can test KUKA iiQoT free of charge on request.