ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Joint Efforts Tout Unique 3D Camera for Autonomous Platforms

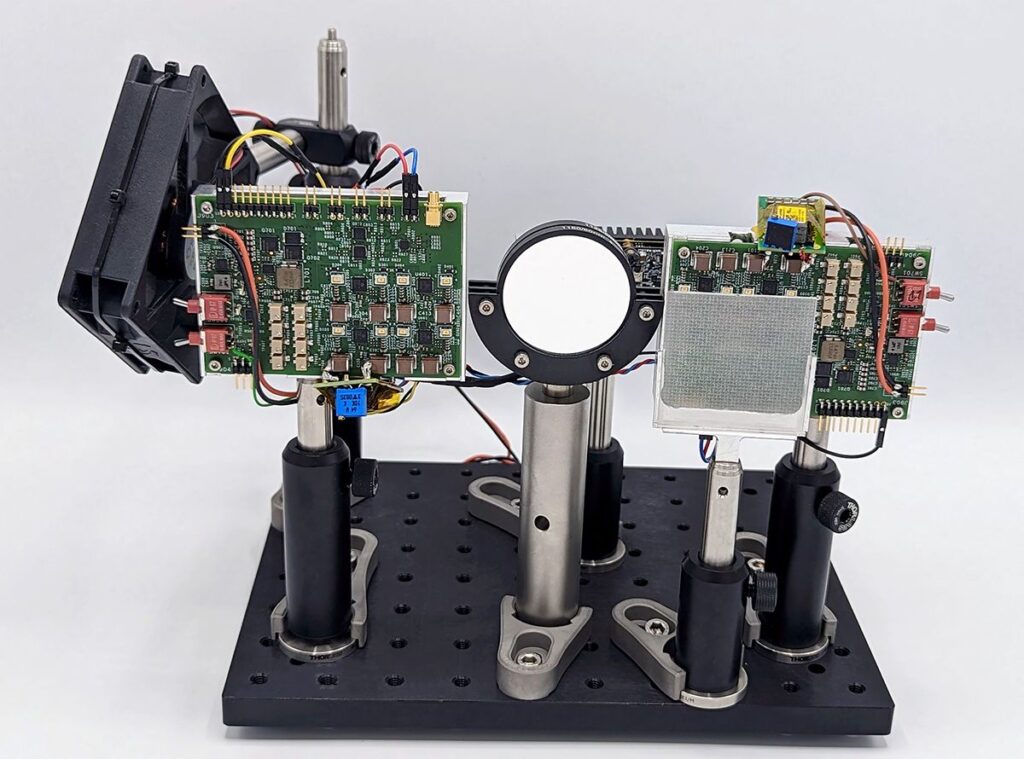

In a joint development Jabil Inc., ams OSRAM AG, and Artilux Inc. combined their respective proprietary technologies in 3D sensing architecture design, semiconductor lasers, and germanium-silicon (GeSi) sensor arrays based on a scalable complementary metal-oxide-semiconductor (CMOS) technology platform to demonstrate a 3D camera that operates in the short-wavelength infrared (SWIR) at 1130nm.

At present, Jabil’s renowned optical design center in Jena, Germany is demonstrating a prototype of the next-generation 3D camera. Specifically, the SWIR camera can seamlessly operate in both indoor and outdoor environments up to a range of 20 meters.

Steep growth in automation is driving performance improvements for robotic and mobile automation platforms in industrial environments. In particular, the industrial robot market is forecast to grow at over 11 percent compound annual growth rate to over US$35 billion by 2029. The 3D sensor data from these innovative depth cameras will improve automated functions. Among them are obstacle identification, collision avoidance, localization, and route planning – key applications necessary for autonomous platforms.

To Usher in a New Paradigm in Sensors

“For too long, the industry has accepted 3D sensing solutions limiting the operation of their material handling platforms to environments not impacted by the sun. The new SWIR camera provides a glimpse of the unbounded future of 3D sensing where sunlight no longer impinges on the utility of autonomous platforms,” said Ian Blasch, senior director of business development for Jabil’s Optics division. “This new generation of 3D cameras will not only change the expected industry standard for mid-range ambient light tolerance but will usher in a new paradigm of sensors capable of working across all lighting environments.”

“1130nm is the first-of-its-kind SWIR VCSEL technology from ams OSRAM. It offers enhanced eye safety, outstanding performance in high sunlight environments, and skin detection capability, which is of critical importance for collision avoidance when, for example humans and industrial robots interact,” says Dr. Joerg Strauss, senior vice president and general manager at ams OSRAM for business line visualization and sensing. “We are excited to partner with Jabil to make the next-generation 3D sensing and machine vision solutions a reality.”

Dr. Stanley Yeh, vice president of platform at Artilux, concurs, “We are glad to work with Jabil and ams OSRAM to deliver the first mid-range SWIR 3D camera with the use of near infrared (NIR)-like components such as CMOS-based sensor and VCSEL. It’s a significant step toward the mass adoption of SWIR spectrum sensing and being the leader of CMOS SWIR 2D/3D imaging technology.”

For nearly two decades, Jabil’s optical division has been recognized by leading technology companies as the premier service provider for advanced optical design, industrialization, and manufacturing. The company’s Optics division has more than 170 employees across four locations. Jabil’s optics designers, engineers, and researchers specialize in solving complex optical problems for its customers in 3D sensing, augmented and virtual reality, action camera, automotive, industrial, and healthcare markets. Additionally, Jabil customers leverage expertise in product design, process development, testing, in-house active alignment (from Kasalis, a technology division of Jabil), supply chain management, and manufacturing expertise.