ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Cognite’s Unique Tool Lifts Industrial Data Modeling

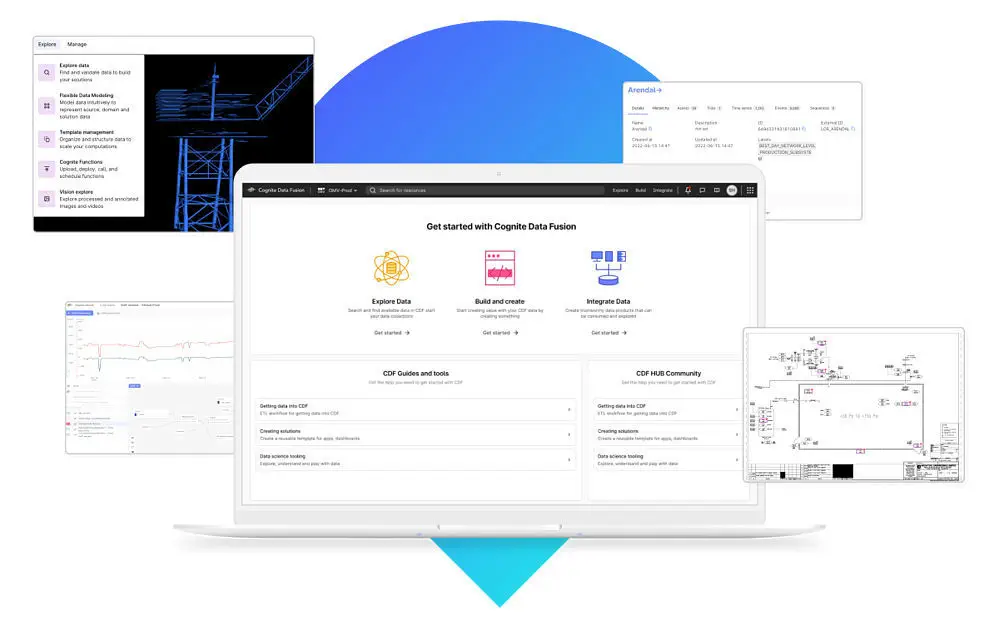

Industrial software leader Cognite has released data product-based, advanced data modeling capabilities coming to its Industrial DataOps platform, Cognite Data Fusion®. Data modeling is critical to build and maintain a standards-based Open Industrial Digital Twin. Managing data models as data products accelerates deployments and drives down the costs and complexity of industrial digital solution scaling through standardization and governance.

Access to Complex Industrial Data

Cognite Data Fusion® enables multiple data users to leverage common data in their unique tools and workflows, all from a single, trusted source. Furthermore, it allows them to build data products and populate data models that reduce the complexity of developing and scaling Asset Performance Management (APM) solutions across the enterprise. Cognite Data Fusion® makes it easy for industrial companies to establish sound DataOps practices where the experts who know the data – data engineers and architects – collaborate with the experts who know the business context of the data – the subject matter experts and data scientists.

Previously, application developers and data scientists needed to query, filter, and stage data explicitly for their needs. Meanwhile, with advanced data modeling practices, the data consumers who use these solutions can find and interpret data more easily than ever before.

Thanks to the more robust search, filter, sorting, and aggregation capabilities, asset-heavy organizations can build, deploy, and scale industrial digital solutions 10-25x faster, resulting in 400 percent ROI, as identified by the Forrester Total Economic Impact™ study.

“With the latest updates to Cognite Data Fusion®, we continue to make it easier to synchronize IT and OT systems and provide simple access to complex industrial data,” said Moe Tanabian, Chief Product Officer at Cognite.

In addition, Tanabian said, “Cognite Data Fusion® makes it simple to connect to and operate data flows for a number of industry solutions. In this release, you’ll see a specific focus on features that help optimize production, reliability, maintenance, and environmental KPIs.”