ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Smarter Factories with Digital Twin Promote Zero Gaps

Following the impact of the coronavirus (COVID-19) pandemic, many industries are beginning to get up on their feet again. For the manufacturing industry, various ways are being adopted to operate within the COVID-19 restrictions. This could mean abiding social distancing rules or operating with as few staff as possible.

With this as a backdrop, a high level of interest is anticipated in the automation of customer sites.

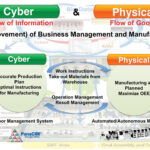

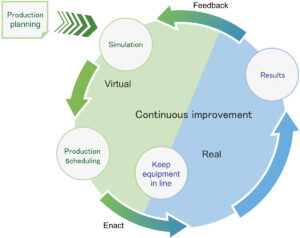

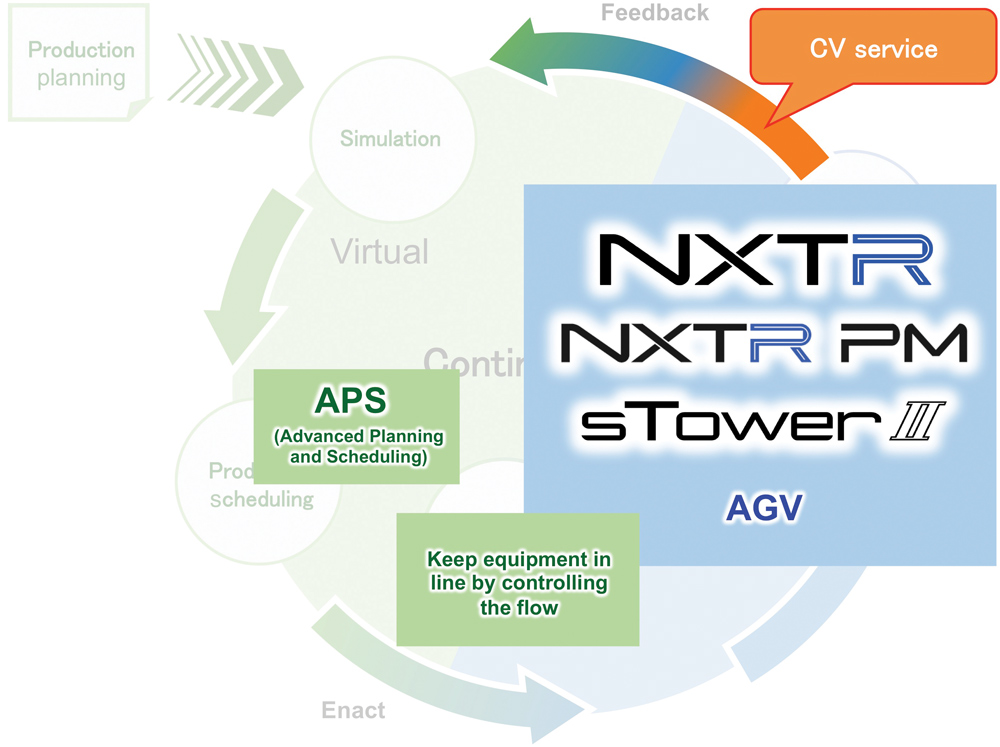

With FUJI Smart Factory, it is possible to attain “digital twin” through automation and digitization to enable production without difference (zero gaps) between the “virtual” and the “real” (Fig. 1).

Realizing Zero Gaps Between Virtual, Real

Configuration proposals using simulation

The two issues that arise from the advancement of automation in production sites are: (1) identifying which processes can be automated, and (2) what automation equipment to purchase. To avoid the risk of purchasing any equipment that only makes minimal contribution to improvement, it is important to check the effectiveness in advance. This is where using simulation technology becomes effective.

Such simulations involve replicating today’s SMT floor in a virtual space. By taking personnel workloads into consideration — something that is hard to quantify in “real” terms, it becomes possible to visualize bottlenecks on the SMT floor. It also becomes possible to visualize the effects from changes to operation and introduction of automation equipment.

Specifying the parameters for each process, including the quantities of automated guided vehicles (AGVs) and automatic part warehouses, number of staff, and designated work paths for SMT floors modeled in a virtual space, is also possible.

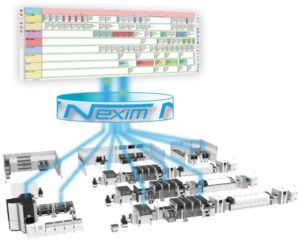

The accuracy of the data used is vital to achieving an accurate simulation. FUJI’s integrated production system Nexim provides finely detailed performance results data and accurate cycle time calculations for each production type and operation method, making it an effective tool for improving the accuracy of simulations.

Scheduling the SMT floor

Production schedules are created for daily production plans by taking into account staff shifts, production order, and line allocation at production sites. However, as factories proceed with automation, more automation equipment is added to the SMT floor, making scheduling more complicated.

By modeling the present lines and automation equipment, personnel skills, and work shifts using a production scheduler, it is possible to allocate tasks to lines and create setups that take production order into account. Also, Nexim can calculate accurate production times when there are differences in tact time for each product type to be manufactured. By linking Nexim with the production scheduler, comprehensive scheduling from part checkout to offline changeover and point of transportation is attained (Fig. 2).

Smart Factory “Monozukuri” Made Possible with NXTR

Issues concerning SMT lines

In present SMT placement processes, there is still a need to employ a large number of people for performing changeover and part supply work. This can cause gaps between production plans and actual production as different operators have different levels of skill and operate under varying conditions.

For example, production may stop if multiple parts run out at the same time in a parts out rush because the operator cannot supply parts on time, or next production could not be started on time because looking for and collecting feeders and reels from part shelving in the preparation stage took longer than expected.

Resolving issues at SMT lines with NXTR

The SMT placement processes that require the most attention from operators is work related to parts, and it is the problems related to these that need to be remedied.

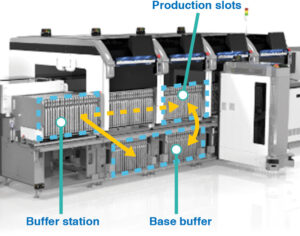

To help improve these processes FUJI has developed the NXTR equipped with the Smart Loader, the first unit for automatically transporting, exchanging, and setting feeders at the machine. This enables automation of part exchange and supply work.

By simply setting feeders at buffer stations on NXTR lines, the Smart Loader exchanges the feeders in production automatically according to parts out warnings and the changeover schedule.

In terms of parts out rushes, a feeder for resupply can be set in an empty slot ready for use when the feeder presently in production runs out of parts, at which point parts will be then picked up from this alternate supply device. The empty feeder is returned, and the alternate feeder is set in the original slot. This allows for some leeway in the timing at which parts need to be supplied, making it possible to avoid parts out rushes. This prevents stops in production caused by part supply issues, and production can proceed as planned.

It is possible to prepare the feeders to be used in next production and store them in the base buffer at the bottom of each module. The feeders are then set to the feeder slots in the module when required by the machine. It is possible to have the feeders for next production present at the machine while performing current production, reducing the work involved for at the time of production changeover. This also leads to a reduction of the space being taken up by feeder stands and carts (Fig. 3).

Printer Evolution in All Directions – NXTR PM

Sustainable QCD through automation

Calls to automate printing processes are increasing, which could be largely due to the transformations taking place at factories in line with progress made in digital transformation, according to FUJI.

The following features meet calls for printer automation:

– Automation of material transport

– Automatic transfer of automatically transported materials (masks, backup blocks)

– Automatic loading to the printer Automating changeover

– Automatic program changeover

– Automatic backup block exchange

– Automatic transfer of solder onto the mask for next production and automatic supply of additional solder

– Automating material supply

– Exchange of empty solder cups and cleaning paper without stopping production

To do this in a timely manner without any excess or deficiencies, it is necessary to link the production scheduler, AGVs, and pick and place machines to the printer.

In terms of quality, FUJI has been strengthening cooperation with solder paste inspection (SPI) machines. SPI measurement data is linked together with print parameters and perpetually stored inside the machine as knowledge data. When creating programs, determining printing parameters is supported by using knowledge data based on the material information while checking the print quality (solder shape, height) and cycle time shown on the printer operation panel.

The printer also reduces line stops by constantly monitoring the SPI measurement data during production, to detect trends that show the occurrence of smearing, and perform cleaning before errors can occur.

CV Service Using Digital Twin

Supporting digital twin

As internet of things (IoT) technologies become commonplace, FUJI sees advancements in connected factories in which production equipment is always connected to a network. Through this, customers will be able to collect the information needed when requesting support faster and with more accuracy. FUJI’s CV service utilizes these kinds of environments to support the feedback between “real” and “virtual” processes, as part of digital twin.

Improving productivity is a lifeline for businesses. The CV service covers the steps from diagnosis, analysis, investigation, proposal making, and final resolution for improving production processes. Production sites, equipment, and service provided by FUJI are the three necessary components for approaching issues, getting the best out of equipment and staff, and having advanced production sites for contributing to higher productivity.

Visualization using diagnosis health charts

A diagnosis of production processes is performed, and the resulting diagnoses are cumulated into a “health chart” to visualize whether the 5M’s (men, machines, methods, materials, and management) are in top shape, and for managing set targets, in order to visualize issues and changes in production. This chart is then shared with the customer. CV service further involves a process of root cause analysis, improvement measure proposals, improvement implementation, training, and result evaluation that leads to resolution of issues. Periodically undergoing this kind of diagnosis is vital to having a factory that maintains high productivity rates.

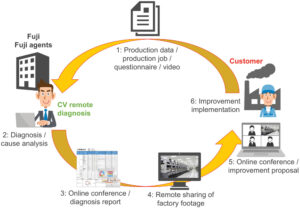

Remote diagnosis

FUJI has begun providing remote diagnosis service to hard-to-visit customers or those that request for CV service at distant sites (Fig. 4). Remote diagnosis is one method for improving work styles by utilizing IoT technologies and digitalization, helping to create new value with close engagement between production sites and FUJI.

Same quality service, timely response

Incorporating FUJI’s activities for identifying reasons behind drops in productivity and quality and addressing their remedies into the CV service platform (CVPF) enables the company to provide the CV service at the same quality and speed to any region.

With CVPF as a foundation, FUJI becomes more capable of providing its service in a timely manner and is working to reduce turnaround times from the analysis of “real” production sites, that is a part of digital twin solutions, to the resolution of issues.

Summary

FUJI Smart Factory has proceeded one step further with the addition of the NXTR and NXTR PM, which were developed with an emphasis on automation.

NXTR, NXTR PM, and automation of part preparation are effective tools in the effort to digitalize the actual results from “real” production sites. Additionally, the CV service improves the accuracy of feedback to “virtual” simulations by identifying problems and their causes through analysis of the gaps between production plans and actual production. It plays an important role to lead to better virtual outcomes by supporting actual cases (Fig. 5).

FUJI continues to support improvements at production sites by working toward enabling production that flexibly supports changes brought about by digital transformation and increased use of digital twin technology, while strengthening the automation and efficiency of work performed by machines and systems.

About This Article:

FUJI CORPORATION provided the contents of the article.