ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Cyber Physical System Heightens Efficiency of Smart Factory

In recent years, on the back of uncertain global situation represented by trade friction and the novel coronavirus disease (COVID-19) pandemic, manufacturing sites are being called on to respond to unprecedently drastic changes, such as social challenges, including manpower shortages or environmental responsiveness, and technology innovation, including the fifth-generation (5G) mobile communication system and autonomous vehicles, or vehicle electrification.

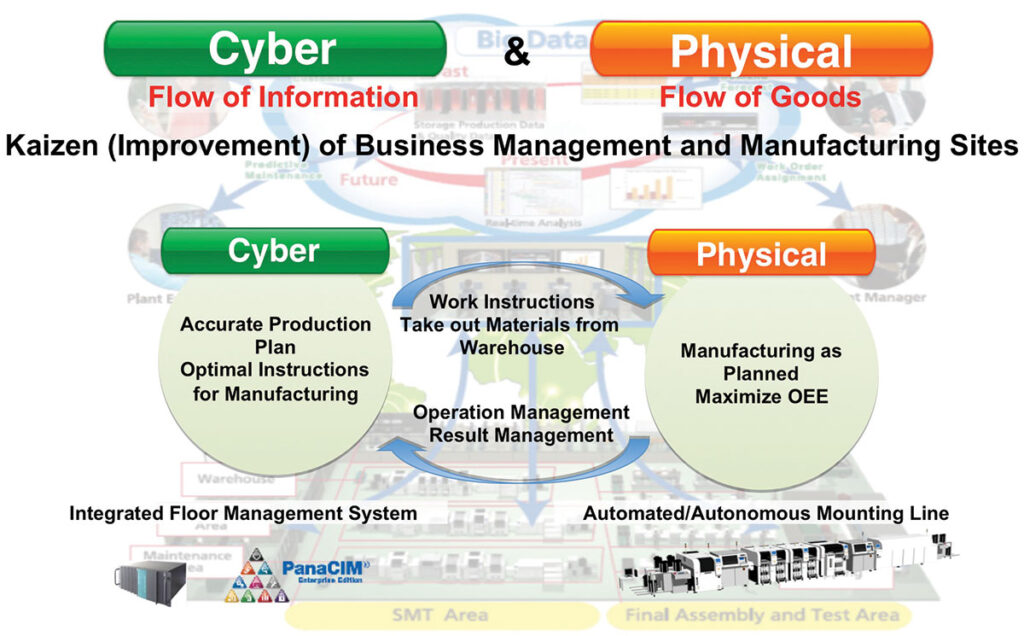

Eyeing an even more efficient manufacturing, with the so-called Cyber Physical System (CPS), making factories smart is proposed with the aim of achieving both “kaizen (improvement) of business management” and “kaizen of the manufacturing site” by reducing the cost of products, eliminating labor shortages, or boosting productivity further.

Panasonic Corporation improves productivity and quality of its electronic component mounting system by increasing performance and evolving functions of individual production facilities. In addition, the company regards a flow of information, including production plans or manufacturing execution instructions, as the Cyber domain, and a flow of goods to carry out manufacturing according to plan and deliver products to customers as the Physical domain; and as the two domains work together at a high level, the company aims to solve problems on the manufacturing site and contribute to customers’ business operations (Fig. 1).

In the Cyber domain, Panasonic’s scheduler, manufacturing execution system, and various management systems work with the customer’s business mission-critical system to formulate an optimal production plan, provide appropriate instructions at the manufacturing site, and visualize the state of operations, thereby expanding the range where Panasonic can help customers revamp their management.

Further, in the Physical domain, in order to carry out production according to plan, Panasonic minimizes various losses to be generated at sites by leveraging autonomous control systems, such as machine to machine (M2M) or process control, thereby boosting overall equipment effectiveness (OEE) in a bid to achieve stable operations or reduce total cost of ownership (TCO).

This report describes how Panasonic serves customers, as the Cyber and Physical domains work in tandem, by sharing solution cases by problem and use scene for the management, floor managers, and line leaders, respectively. It also presents the company’s philosophy of “a factory that boosts value autonomously” or an ideal state of offering value that company aspire to, which Panasonic build in collaboration with customers.

For the Management: Support for Decision Making

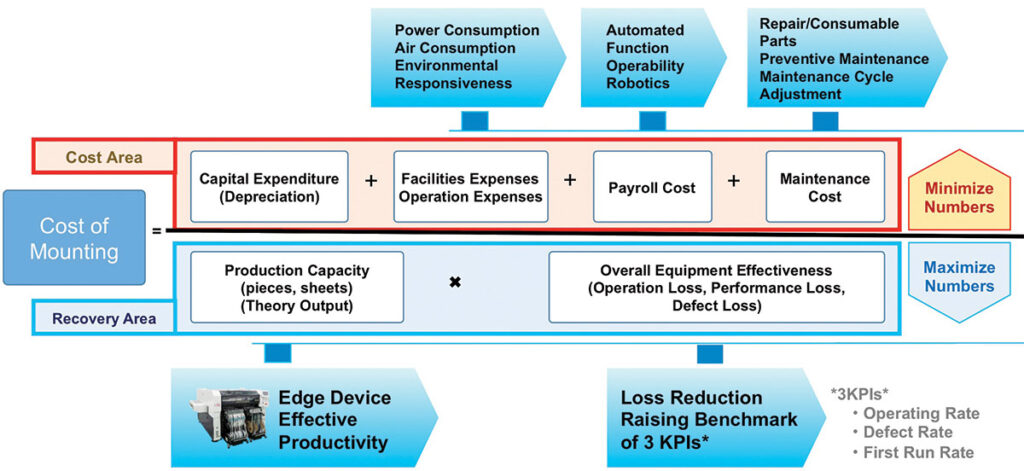

The managerial responsibilities are to inject management resources to meet the management goal and deliver results. Specifically, as Fig. 2 shows, it means that by minimizing the cost area while maximizing the recovery area, the company has to reduce the cost of manufacturing and maximize revenues to improve cash flows. In order to do so, the company needs to identify the real situation at the manufacturing site quickly and accurately, such as the state of inventories in the process or production operations, and various losses that lower efficiency, before making a decision in running a factory, including a new investment decision.

The authors will discuss this more in detail in the following sections. Panasonic develops and offers a wide array of solutions that link business management with the manufacturing site involved in the mounting process in collaboration with customers’ systems. Besides, by using the integrated Manufacturing Execution System (MES) package CYPROS, the progress and q actual results of not only the mounting process but also the entire process at the manufacturing site from acceptance or delivery of materials and that of finished products are becoming visible. Thereby, Panasonic supports more viable business decision making with the situation of the whole factory taken into account and contribute to maximizing the customer’s operational results.

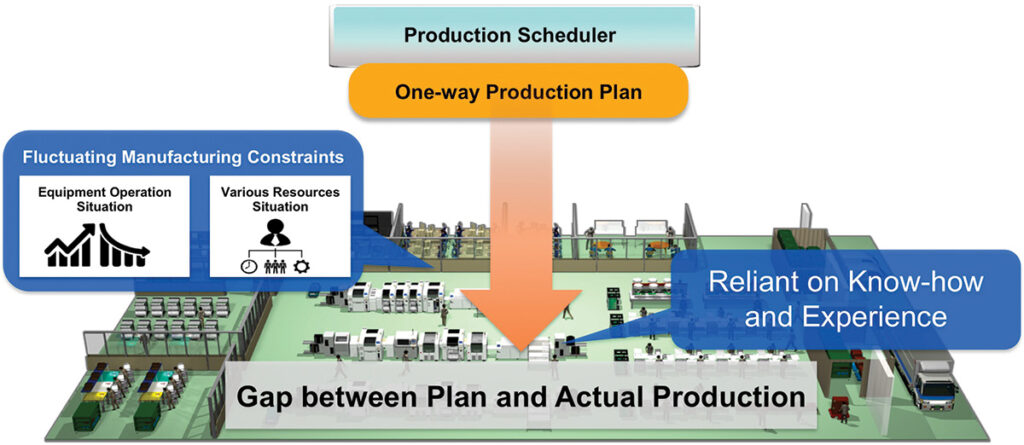

For Floor Managers: Maximum Use of Resources

Floor managers hope to be able to maximize resources at the site and boost productivity as much as possible. To meet this goal, it is essential to have an optimized production plan based on resources information, including people at the site, and execute production without halting people and goods according to the plan. Having said so, however, in reality, floor managers are unable to link it with fluctuating capacity utilization or situations of various resources; thus, they carry out a one-way production plan that does not match the site as appropriate while making adjustments through skilled workers’ experience and seat of their pants (Fig. 3-1). As a result, the reality is that many factories are unable to maximize productivity on the manufacturing floor.

Production plans that fit the mounting site

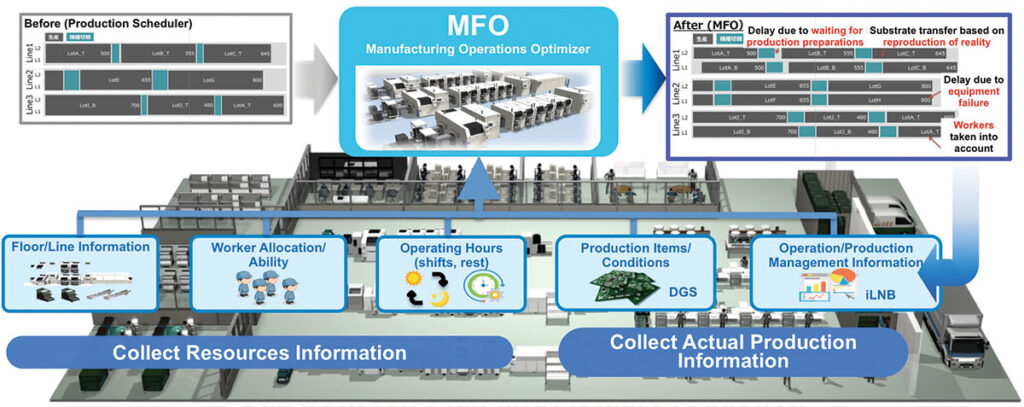

Panasonic has developed Manufacturing Operations Optimizer (MFO) that allows floor managers to formulate an accurate production plan for the whole mounting floor and maximize resources at the site.

Accurate plans

MFO enables floor managers to create a virtual mounting floor as a whole in cyberspace and exercise autonomous simulation that takes actual production performance into account so that they can formulate a highly accurate production plan that fits a customer’s manufacturing site (Fig. 3-2).

- – Reproduce behavior specific to facilities for a mounting line made up of more than one vendor;

- – Take into account a flow from substrate transfer of a single facility to that on a line;

- – Reproduce a variety of losses, such as a halt due to an error, supply work, or model changeover, in a future plan;

- – Manage workers across lines and off-line setup on the floor.

Maximizing productivity by making the most of resources

MFO makes it possible to formulate a viable production plan by taking into account the numbers of carriages/feeders/nozzles/workers and adjusting finite resources in an arbitrary amount of time. Further, by formulating a preparatory plan with the minimum number of part setup and off-line setup in consideration of the layout of components for a component mounting machine, it provides a production plan that maximizes productivity.

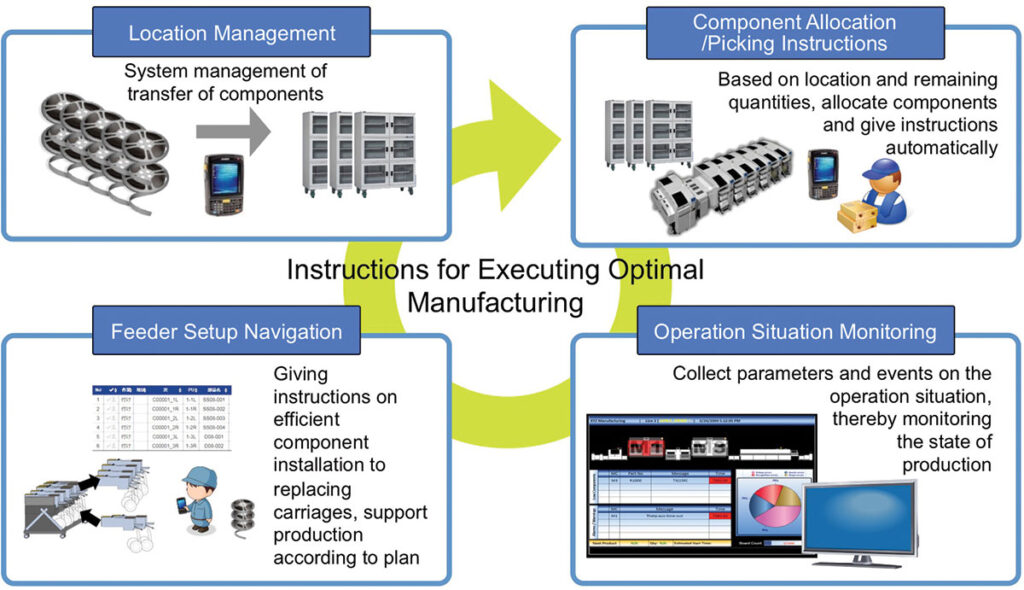

Optimal manufacturing linked to production plans

The company’s PanaCIM mounting MES software manages the location of materials, allocates components needed for production, and gives instructions on picking. Besides, it monitors the progress of production and notifies a handy scanner held by a worker of information on an event of equipment. Then, by using its feeder setup navigator, it gives instructions on the efficient removal and installation of components to each replacing carriage (Fig. 3-3). In this way, necessary materials are injected into the production site at the right timing, thereby realizing production as optimally planned.

On top of these, in terms of the recent growing requirements for automation and labor savings to not rely on manpower, automated items on the mounting floor have been expanded. They are carriage or screen mask replacement at the time of automatic model changeover using an automated guided vehicle (AGV) and material transfer from a component warehouse to a production line at the time of production to name but a few. These new robotics technologies are linked to the existing production site via the system to realize production as planned while exercising control according to the situation.

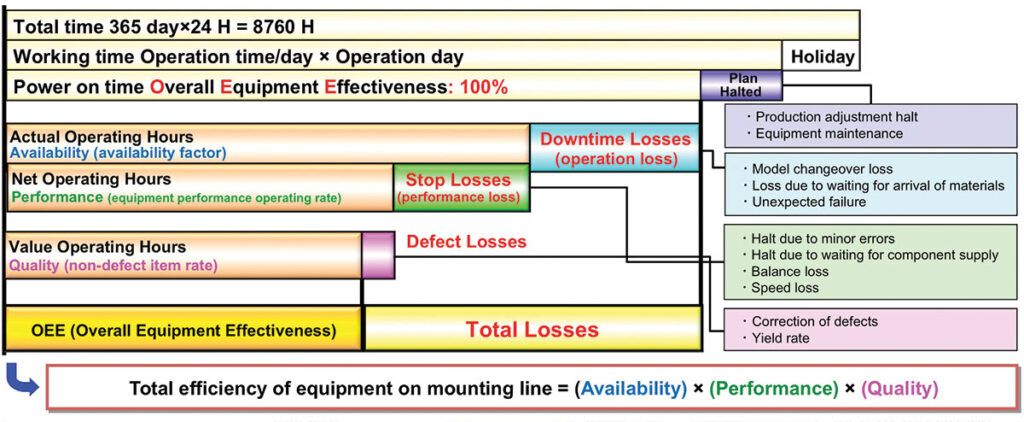

For Line Managers: Maximizing OEE

Line managers desire to realize the optimal production plan formulated through “Cyber” with high quality. In many manufacturing sites, however, people who rely on their experience and fly by the seat of their pants manage the elements of manufacturing (equipment, materials, etc.); thus, variation due to human skills cannot be prevented, making it difficult to realize quality manufacturing according to production plans.

In order to achieve the optimal production plan, line managers have to minimize losses while maximizing OEE (Fig. 4-1). Further, by minimizing losses, they can suppress variation, resulting in quality manufacturing.

Panasonic offers and evolves solutions for reductions, including automation, labor-saving, M2M, and process control, to address various losses so that the difference from the plan formulated by MFO can be minimized to produce the results that the management expects to see.

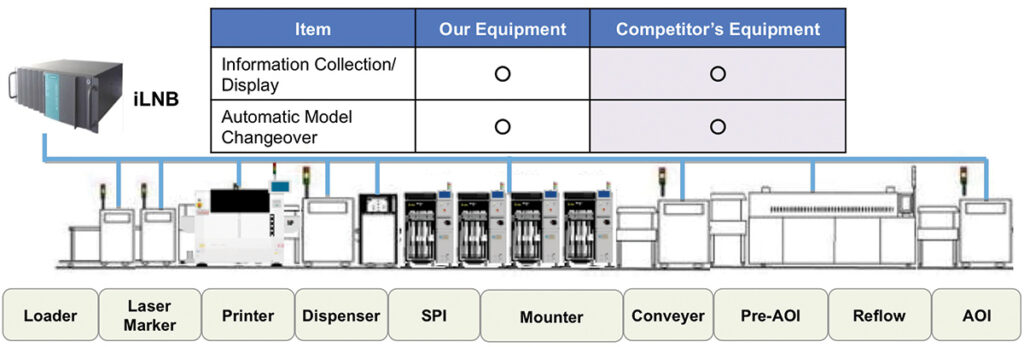

Operational loss reduction

The company’s integrated line management system, iLNB or Integrated Line Network Box, makes it possible to manage the entire mounting line whether it is the company’s or others’. This allows line managers to manage all substrates on a mounting line and make automatic model changeover sequentially as production is completed, thereby achieving reductions in operational losses (Fig. 4-2).

Performance loss reduction

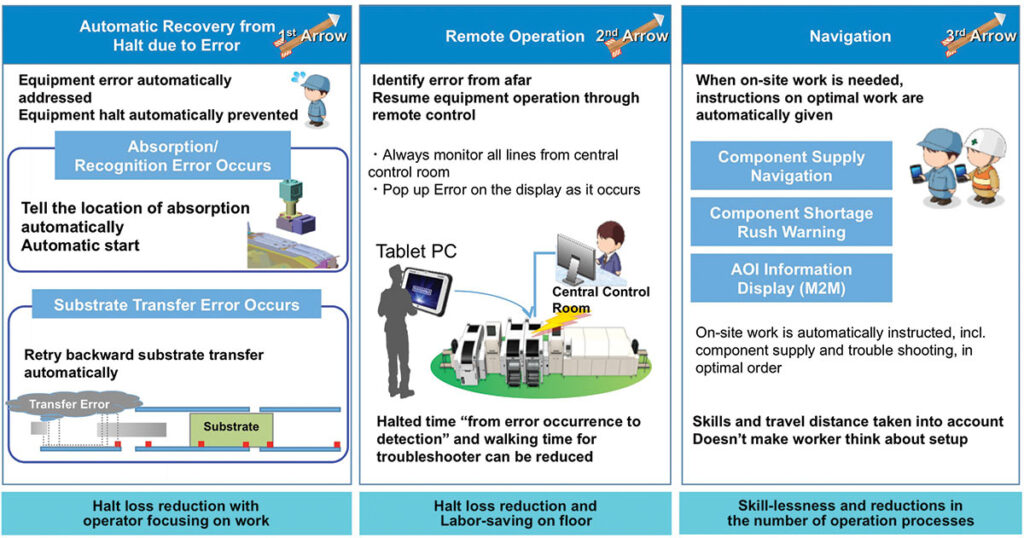

Losses in component supply can be reduced by using an auto load feeder. Moreover, as a way to reduce losses due to a halt resulting from an pickup/recognition error, a skill-less labor-saving function is provided centered on the three arrows (Fig. 4-3).

Defect loss reduction

Advanced process control

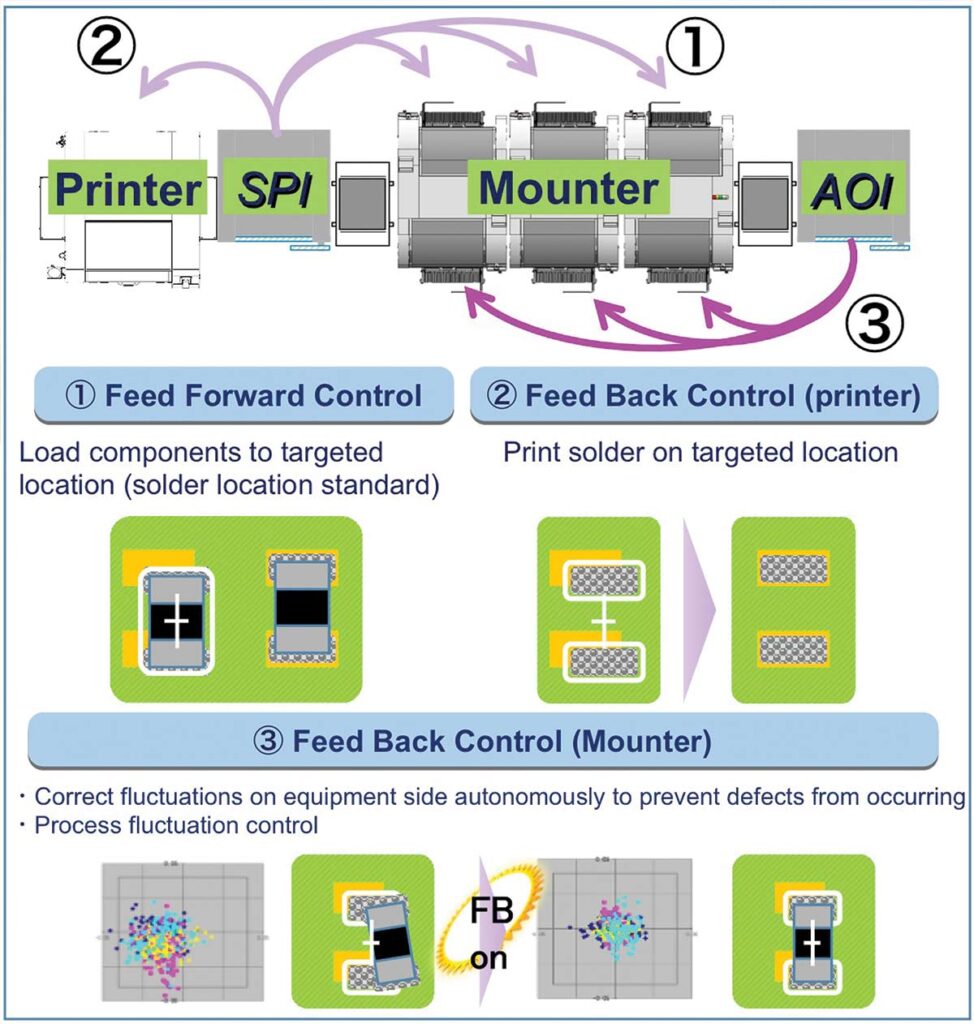

By feeding fluctuations due to changes in people, equipment, materials, and methods forward and back to equipment based on the results of measuring using solder paste inspection (SPI) and automated optical inspection (AOI) devices, variations in printing and mounting are corrected autonomously and mounting quality is stabilized (Fig. 4-4).

Maintenance notification service

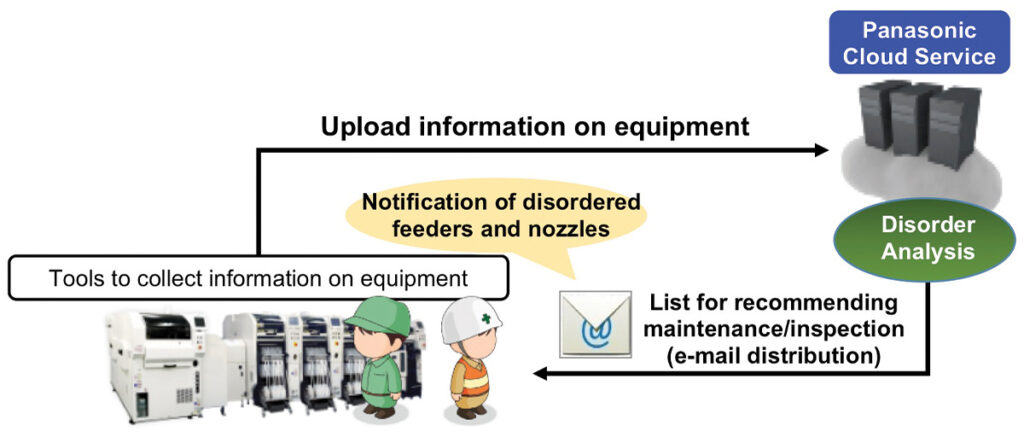

By leveraging cloud and analytical systems, the system performs a log analysis for equipment. It looks into a declining trend in the adsorption state that is hard for humans to notice, identifies feeders and nozzles that need to be inspected and maintained preferentially, and sends notifications to customers (Fig. 4-5).

Panasonic will continue to analyze and learn data using AI to accelerate evolution further.

Conclusion

As it stands, solutions the authors have described include quite a few cases that still need work or judgment by humans in the phase of visualization using simulation. However, Panasonic intend to keep expanding the range of more autonomous real-time solutions across the mounting floor and factory as a whole to move Panasonic’s Cyber & Physical Solution initiative forward, thereby linking customers’ management with the manufacturing site to create factories that enhance value autonomously in collaboration with them.

About This Article:

The authors are Toru Ikeda, Manager, and Ryou Noudomi, Supervisor, from the Circuit Formation Processes Business Group, Circuit Formation Processes Coordination Department, JISSO Software Development Department, Panasonic Smart Factory Solutions Co., Ltd., and Hirokazu Takehara, Supervisor from the Manufacturing Process Solution Management Department, Solution Engineering Department 2, IFM Development Section 2, Connected Solutions Company, Process Automation Business Division, Process Innovation Center, Panasonic Corporation.