ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

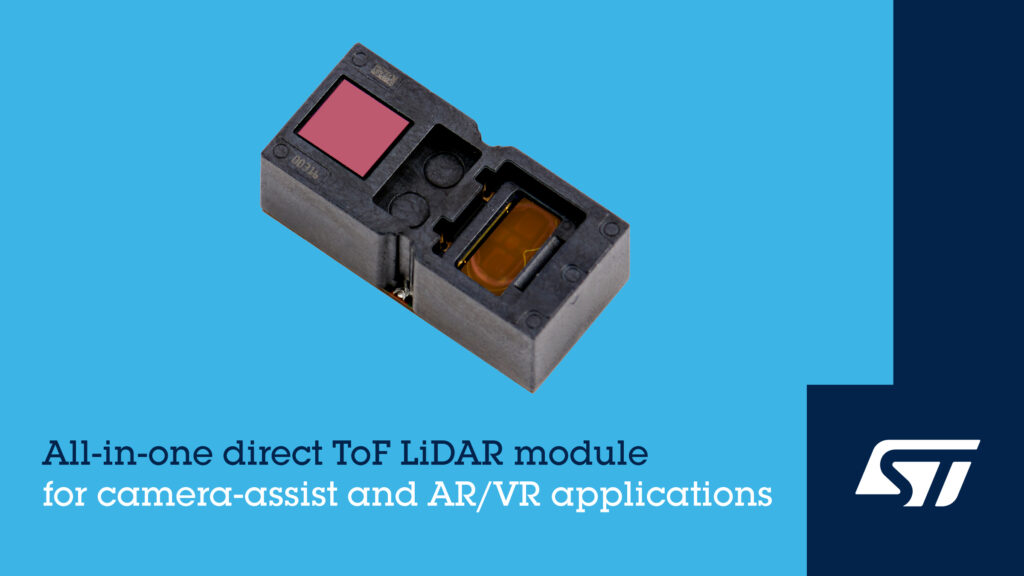

STMicroelectronics has announced an all-in-one, direct Time-of-Flight (dToF) 3D LiDAR module, which comes with market-leading 2.3k resolution. Moreover, the company also revealed an early design win for the world’s smallest 500k-pixel indirect ToF sensor.

Alexandre Balmefrezol, General Manager, Imaging Sub-Group at STMicroelectronics said ToF sensors are driving exciting new capabilities in smart devices, home appliances, and industrial automation. Particularly, Balmefrezon said the company has already delivered two billion sensors to the market. Thus, it will continue to extend its unique portfolio, which covers all types from the simplest single-zone devices to the latest high-resolution 3D indirect and direct ToF sensors.

Furthermore, Balmerfrezol said, “Our vertically integrated supply chain, covering everything from pixel and metasurface lens technology and design to fabrication, with geographically diversified in-house high-volume module assembly plants. (Thus, enabling to) deliver extremely innovative, highly integrated, and high-performing sensors.”

State-of-the-Art Performance

The new VL53L9 is a new direct ToF 3D LiDAR device with a resolution of up to 2.3k zones. Moreover, it comes integrated with a dual scan flood illumination, a unique in the market. Thus, the LiDAR can detect small objects and edges and can capture both 2D infrared (IR) images and 3D depth map information.

It comes as a ready-to-use low-power module with its on-chip dToF processing. Hence, requiring no extra external components or calibration. Additionally, the device delivers state-of-the-art ranging performance from 5cm to 10m.

VL53L9’s suite of features elevates camera-assist performance, supporting macro up to telephoto photography. It enables features such as laser autofocus, bokeh, and cinematic effects for still and video at 60fps (frame per second). Virtual reality (VR) systems can leverage accurate depth and 2D images to enhance spatial mapping for more immersive gaming and other VR experiences like virtual visits or 3D avatars.

In addition, the sensor’s ability to detect the edges of small objects at short and ultra-long ranges makes it suitable for applications such as virtual reality or SLAM (simultaneous localization and mapping).

Mobile Robot Application

ST is also announcing news of its VD55H1 ToF sensor, including the start of volume production. Furthermore, it also confirmed early design win with Lanxin Technology, a China-based company focusing on mobile-robot deep-vision systems. MRDVS, a subsidiary company, has chosen the VD55H1 to add high-accuracy depth-sensing to its 3D cameras. The high-performance, ultra-compact cameras with ST’s sensor inside combine the power of 3D vision and edge AI, delivering intelligent obstacle avoidance and high-precision docking in mobile robots.

In addition, aside from machine vision, the VD55H1 is ideal for 3D webcams and PC applications. Most importantly, it also suits 3D reconstruction for VR headsets, people counting and activity detection in smart homes and buildings. It packs 672 x 804 sensing pixels in a tiny chip size and can accurately map a three-dimensional surface by measuring distance to over half a million points.

ST’s stacked-wafer manufacturing process with backside illumination enables unparalleled resolution with smaller die size and lower power consumption than alternative iToF sensors in the market. Thus, these characteristics give the sensors their excellent credentials in 3D content creation for webcams and VR applications. These include virtual avatars, hand modeling, and gaming.

First samples of the VL53L9 are already available for lead customers and mass production is scheduled for early 2025. The VD55H1 is in full production now.