ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Stratasys Now Brings High Def Printing to its Lineup

Finer detail and even greater precision are coming to Stratasys’ SAF™ technology. Specifically, Stratasys has announced its new SAF™ HighDef Printing capabilities and also launched the H350™ printer, Version 1.5 (V.1.5). Hence, this will expand SAF adoption with additional applications and use cases for a growing set of manufacturing end markets.

Introducing High Definition

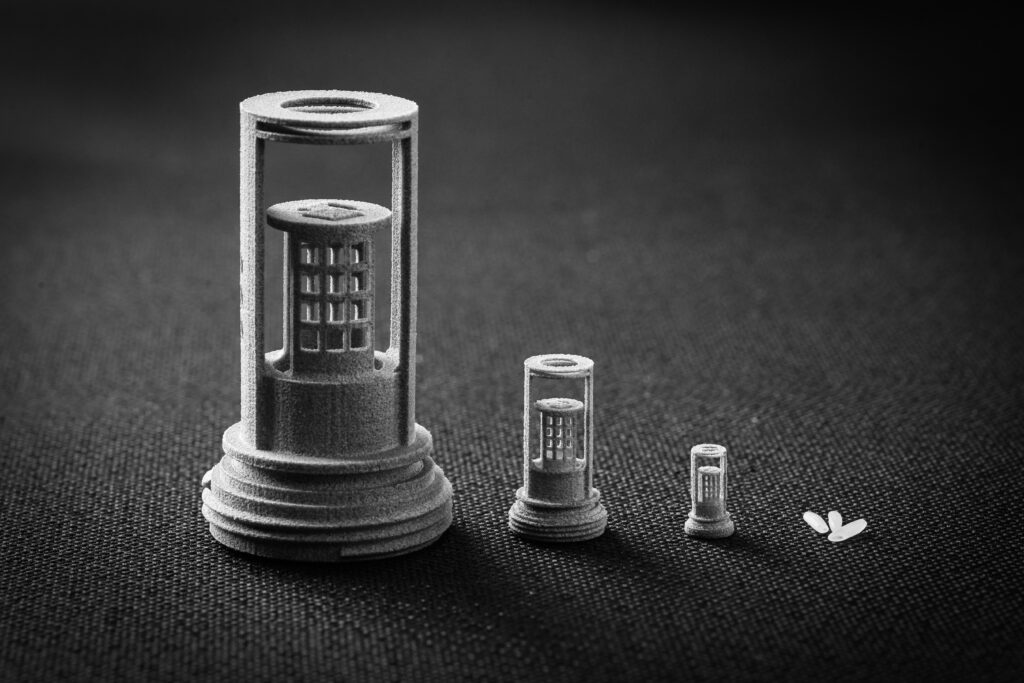

Stratasys’ new HighDef Printing capabilities allow more exact, high-definition printing with detailed resolution. This will allow manufacturers to rapidly scale their additive manufacturing through reliable repeatability. At the same time, it will also create more intricate parts and will expand their design capabilities.

Customers from industries such as aerospace, automotive, and healthcare can take advantage of SAF thermal control to create applications that require smooth, precise features like gears and mechanisms.

“High-definition printing enables tighter tolerances, moving assemblies, and a new range of applications for SAF customers,” said Adam Ellis, Corporate Applications Manager, Stratasys. In addition, Ellis noted, “Bringing HighDef to our customers will help us expand and improve their capabilities and increase their adoption of 3D printing in manufacturing roles.”

Delivered as part of a firmware update, Stratasys’ HighDef Printing will be backward compatible with previous H350 models. More importantly, it will be available to customers at no additional cost.

The New H350

In addition, Stratasys is introducing the new H350 V1.5 printer. This new printer has improved sensors and remote service capabilities, making the printer easier to operate and service. The H350 V1.5 will also come with the new Stratasys HighDef Printing firmware update.

“The new capabilities and the upgraded H350 align with the performance needs that our customers indicated to us. That will allow them to further benefit from additive manufacturing and SAF technology in particular,” said Torben Lange, Vice President, SAF Research & Development, Stratasys. “New applications and use cases will allow manufacturers to scale their production, with more intricate parts, without compromising speed or quality.”

-26 April 2024-