ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Innovative Tech to Offer Better Fault Detection

The Fraunhofer Institute for Photonic Microsystems IPMS presents a groundbreaking demonstrator for predictive maintenance of industrial equipment. Accordingly, the demonstrator uses advanced sensor technology combined with artificial intelligence (AI)-based data processing. Thus, detecting potential machine damage at an early stage and avoid costly downtime.

Based on the results of the iCampus project ForTune, Fraunhofer IPMS has developed a new demonstrator. Specifically, combining sensor technology, data acquisition and AI-based data evaluation for condition monitoring and predictive maintenance. This opens up new possibilities for the preventive maintenance of plants and machines.

Fraunhofer IPMS uses its expertise in edge computing and real-time data transmission. Dr. Marcel Jongmanns, project leader at Fraunhofer IPMS, explains: “Our solution enables precise condition monitoring of machines through the use of sensors and intelligent data analysis. By integrating AI into the sensors, we can detect damage before it occurs, optimize maintenance intervals and minimize downtime.”

Increased Prediction Accuracy

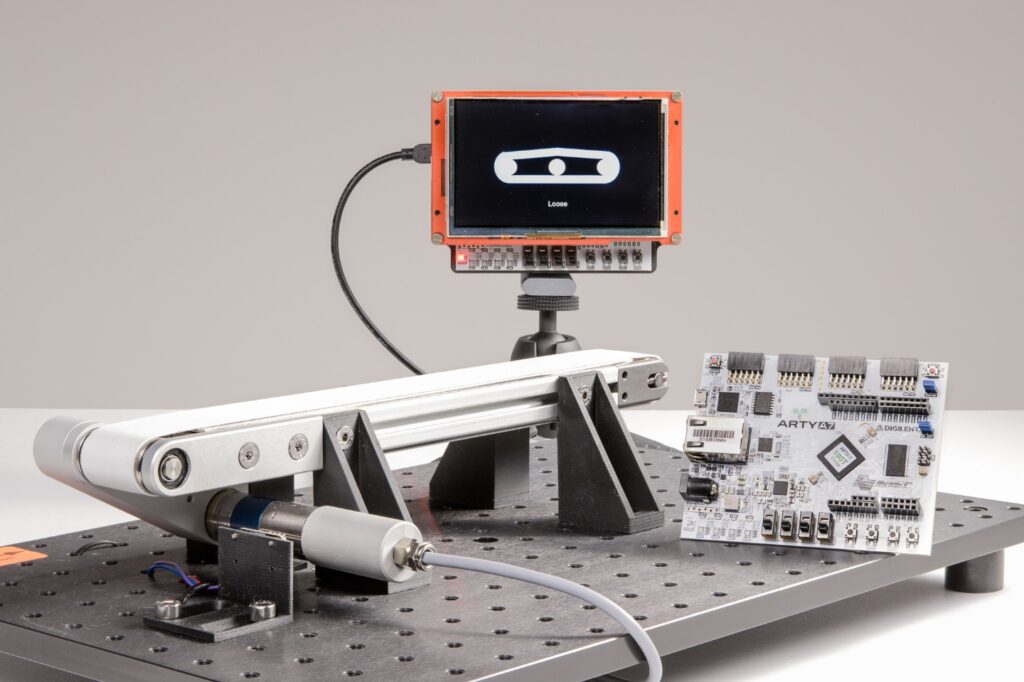

The showcase displays a miniaturized conveyor belt and demonstrates the performance of a novel toolbox for industrial plant monitoring. The demonstrator uses multimodal sensors. The sensor function records accelerations in the spatial directions and the corresponding rotation rates. In addition, magnetic field sensors and acoustic or ultrasonic sensors monitor the industrial equipment.

Moreover, the system provides two main functions: Belt tension detection and jam detection. The AI models come from extensive data analysis and enable accurate prediction of damage. On the other hand, to increase the accuracy of the models, real-time calibrations will help adapt the system to new environments.

The Fraunhofer IPMS system solution aims to combine the in-house sensors with its edge computing unit based on RISCV architecture. Specifically, for efficient data processing directly at the point of use. This enables complex AI operations and real-time analysis.

Changing environmental influences can be directly modeled or taken into account in the analysis. This enables the integration of a large number of sensors and significantly increases the accuracy of predictions about the condition of the industrial equipment. Moreover, it also overcomes existing limitations in computing power for real-time modeling in embedded systems.

The expertise of Fraunhofer IPMS in the field of sensor technology and AI evaluation enables the continuous further development of the technology. Existing partnerships with companies such as Vetter Kleinförderbänder GmbH demonstrate the industry’s interest in such solutions.

During the SENSOR+TEST trade fair from June 11 to 13, 2024 in Nuremberg, visitors will have the opportunity to view the demonstrator at the Fraunhofer IPMS booth 1-317. The scientists will be on-site to answer questions and provide insights into the research work.

06 June 2024