ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Japan 3D Printer Pitches New Upgrade of Flagship Unit

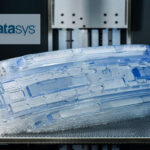

Japan 3D Printer Co., Ltd. has launched new products under Raise3D, a trusted brand that provides 3D printers with excellent quality and repeatability. Specifically, the new high-end models of the Raise3D Pro3 Series, Raise3D Pro3 HS and Raise3D Pro3 Plus HS, are now available beginning July 1.

Promotes Greater Stability, Productivity

Mainly, the Pro3 HS Series was developed for greater stability, repeatability, superior usability, and productivity. This is the latest model to maintain the design, rigidity, accuracy, and basic functions of Raise3D’s flagship Pro3 Series, while improving various features such as updated parts.

Primarily, it features an upgrade of each component, such as the motor, to achieve quieter noise and more precise control. Also, it is compatible with high-speed printing as standard feature.

The stability inherited from the Pro3 Series and the new automatic filament switching function enable continuous printing of two spools. Also, the optional 2.5kg filament box enables high-level productivity.

Pro3 HS Series Product Details

The company made improvements to the new model as follows:

・High-speed modeling function as standard equipment;

・Renewal of XY-axis motor: Vibration reduction and quietness during high-speed modeling;

– Improved hot end unit: Improved modeling stability.

– Improved build platform: The bed has been reduced to a thinner profile.

・Improved motor performance: Calibration is no longer necessary due to the reduction of vibration itself and the update of the internal algorithm for vibration isolation.

Additionally, the company integrated new features to the updated model:

・Automatic material switching function: Enables continuous printing;

・Compatible with external filament boxes: Enables large-scale modeling that consumes up to 5kg of material;

・Automatic unloading function

・RFID function: Prevents molding failures due to human error, such as recognizing materials and modeling different materials. (* This function can be used after the RFID tag-equipped spool is distributed.)

・Hot end unit dedicated to reinforced fiber resin materials: In addition to the standard high-speed hot end on the left and right, it includes a hot end unit for reinforced fiber resin filaments equipped with a nozzle using silicon carbide (SiC). The SiC nozzle greatly reduces the wear caused by the reinforced fiber resin filament. Also, it enables stable modeling.

Even after the launch of the Raise3D Pro3 HS Series, the Raise3D Pro3 Series will still be available in the market.

This is an online translation of a news release in Japanese with slight editing made by Dempa.

-01 July 2024-