ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Mitutoyo’s New Sensor to Upgrade Surface Measurement

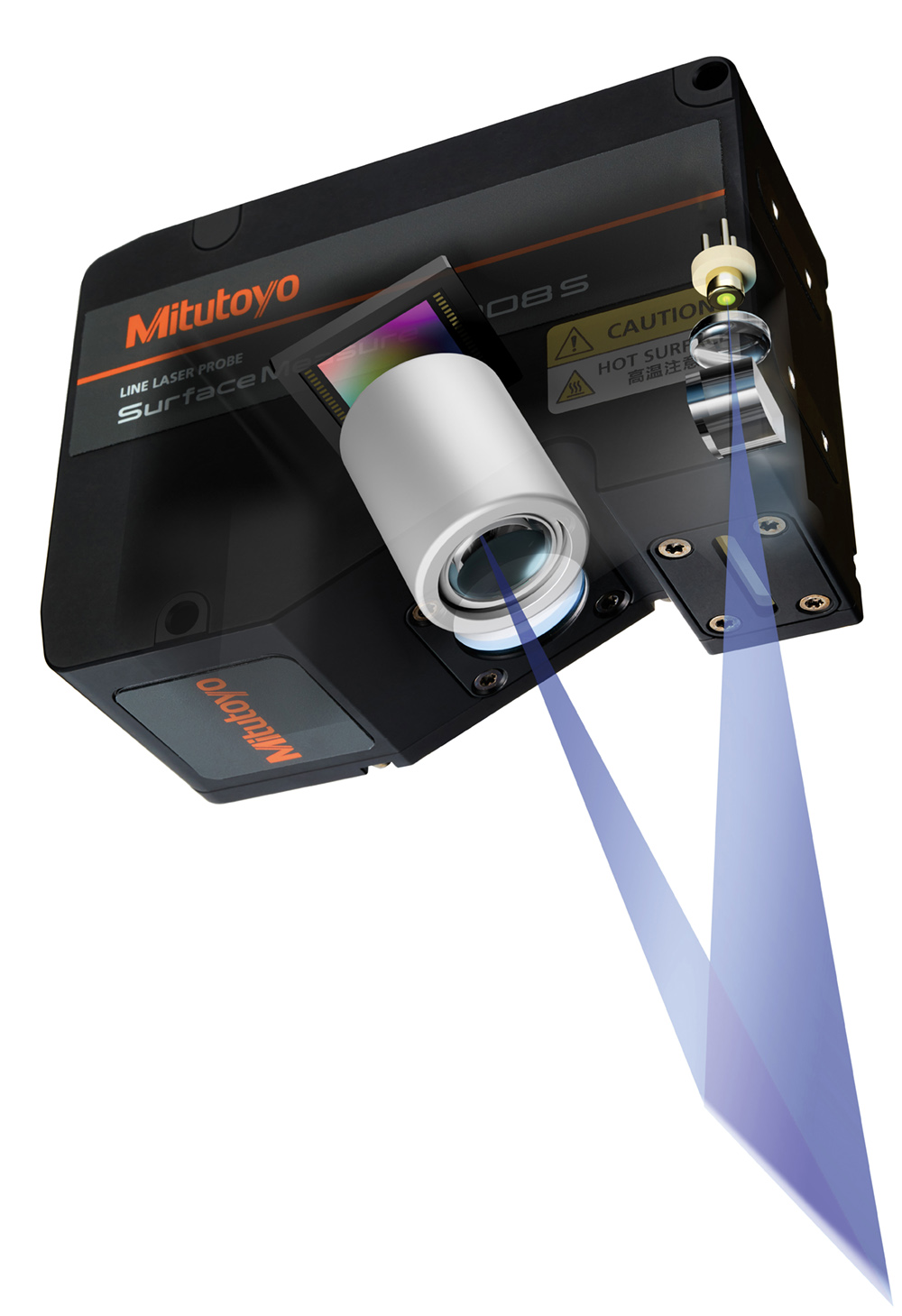

Mitutoyo America Corporation, a leading manufacturer of precision metrology instruments and solutions, is proud to announce the release of its innovative SM1008S, the first non-contact line-laser sensor in the Mitutoyo Surface Measure product line.

The Surface Measure 1008S aims to disrupt the surface measurement processes across a wide range of industries. Primarily, it can offer unprecedented precision and accuracy, even with in-line and near-line shop floor applications. Additionally, the SM1008S leverages a propriety Mitutoyo optical system alongside its traditional sensor technology to deliver versatile performance that includes 2D profile measurements and comprehensive 3D dimensional inspections.

Key Features and Benefits

Exceptional Precision and Repeatability

The SM1008S boasts an accuracy of 20µm and a Z repeatability of 0.5µm, ensuring reliable and consistent measurements. Particularly, this precision level allows for stable inspection and measurement of intricate details and complex surfaces.

Integrated Smart Software

Additionally, the sensor’s on-board software includes a wide array of measurement tools such as height, width, volume, flatness, pattern matching, gap & flush, optical character recognition (OCR), barcode reading, and various defect detection tools. These features eliminate the need for additional controllers or complex programming, simplifying setup and operation.

Robust and Versatile Design

Designed to withstand demanding environments, the SM1008S achieves an IP67 protection level. Particularly, it supports automated measurements with high-speed profile acquisition (up to 10kHz). Also, it features a parts-matching function for consistent application regardless of part orientation.

Wide Range of Applications

Mainly, the new sensor suits industries including electrical, electronics, semiconductor, automotive, food, medical device, and pharmaceuticals.

The SM1008S facilitates 100% in-line inspection, enhancing quality control and productivity.

-19 July 2024-