ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Toyo Technica Sensor Boosts Dynamic Strain Sensing

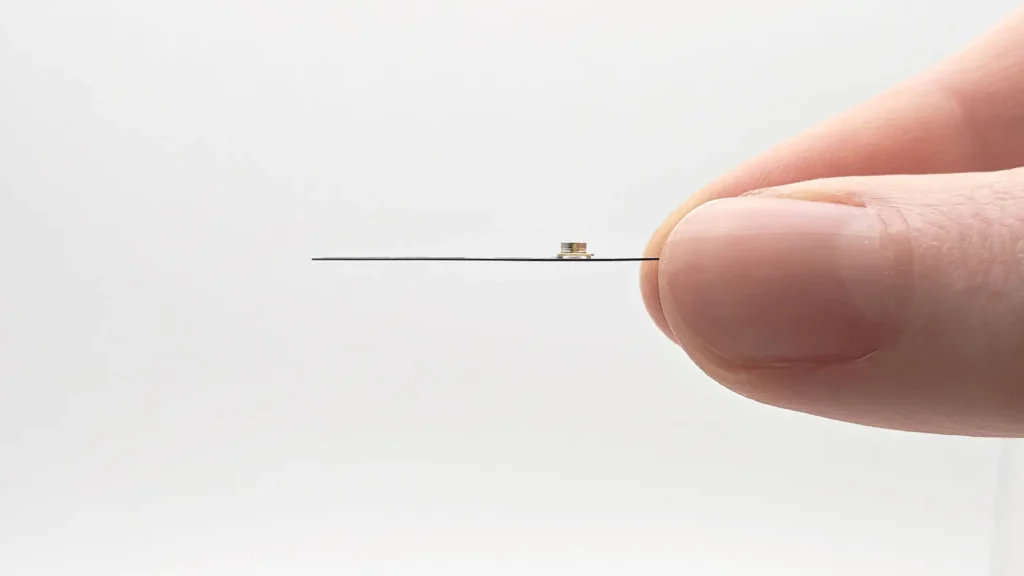

Toyo Technica Co., Ltd. has signed an exclusive distributor agreement with Wormsensing SAS (Worms) in Japan and began selling the piezoelectric dynamic strain sensor “Dragonfly” on July 1, 2024.

Although this product is 0.2mm thick, it can detect minute strains with high accuracy. Also, since it can be attached to curved surfaces, it is possible to sense even in narrow or curved places where it was difficult to attach the sensor in the past.

In addition, it is durable with special processing using Worms’ proprietary patented technology. Further, it provides stable performance even in harsh environments and can collect data continuously over time.

It supports a wide variety of applications in the field of R&D and condition monitoring in various fields, including automobiles, semiconductor manufacturing equipment, power generation equipment, home appliances, and production equipment.

Dragonfly piezoelectric dynamic strain sensor

Background

Conventionally, the measurement of dynamic strain (the dynamics of the object due to the load, i.e., the deformation of the object due to the excitation force of the alternating current) has been used in the fields of engineering research, industrial applications, and safety evaluation as a means of obtaining the behavior and fatigue state of the device to be measured.

Generally, strain gauge sensors and piezoelectric sensors measure dynamic strain. While strain gauge sensors are inexpensive and thin, they cannot detect minute strain amounts due to their low sensitivity. Also, their durability is low and there are concerns about breakage.

Meanwhile, piezoelectric sensors are highly sensitive and can detect minute strain, but they are expensive and thick. Therefore, because of these circumstances, it is difficult to detect dynamic strain with high accuracy in narrow and curved areas. Also, they have been used only for specific evaluation purposes.

Primarily, Dragonfly achieves a sensor thickness of only 0.2mm using Worms’ proprietary patented technology. It features a sensitivity 1,000 times that of conventional strain gauge types, enabling accurate capture of minute strain. In addition, the width of deformation is more than three times wider than that of the piezoelectric element type, and it is possible to capture large deformations. Moreover, the response frequency range is wide, from 0.02Hz to 100kHz, making it suitable for frequency analysis.

In summary, it is a new solution for dynamic strain measurement, optimized in terms of integration, performance and measurement cost by special processing of piezoelectric ceramic thin film.

Main Features

- Approximately 1,000 times more sensitive than strain gauge type despite being only 0.2mm thick;

- Can be attached to curved surfaces and is compatible with curved surfaces with a minimum radius of 2cm.

- Made of specially processed material. It is durable and allows long-term and continuous data collection.

- Supports both charge output and constant current drive (IEPE). In addition to the charge output type, which emphasizes compactness and lightweight, it also supports constant current drive (IEPE). Thus, it overcame the effects of cable noise and cable capacitance, which are the weaknesses of the charge output type. Also, it supports measurement with long cable lengths.

This is an online translation of a Japanese press release with slight editing made by Dempa.

-30 July 2024-