ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

TDK Piezo Tap™ Revolutionizes Touch Sensor Technology

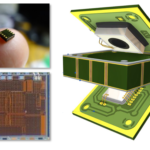

TDK Corporation has been developing the Piezo Tap™, an ultra-compact, high-sensitivity touch switch (touch sensor) that uses piezoelectric technology. At present, it is in the process of creating a new ultra-compact, high-performance type that measures 5.5mm2 and is approximately 0.3mm thick. The company eyes mass production of the particular Piezo Tap™ product in the first half of 2025.

Operable Using Gloves or Wet Hands

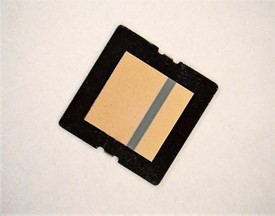

Piezo Tap™ is an ultra-compact and thin piezoelectric switch that uses the piezoelectric effect phenomenon. The conventional capacitive touch sensors are impossible to operate with gloves and malfunction when exposed to sweat or water. These are their weaknesses. Meanwhile, Piezo Tap™ detects pressure using the piezoelectric effect. It converts the minute displacement caused by a touch push into a voltage using a piezoelectric element. Therefore, it is possible to operate it while wearing gloves and in wet environments. Furthermore, unlike the capacitance type, attaching it to either conductors or insulators is possible.

Quest for Seamless Operation

TDK began developing Piezo Tap in 2021 in response to the trend towards seamless feature, which removes the unevenness of physical buttons in mobile devices and household appliances.

In many cases, capacitive sensors are generally used in seamless applications. However, considering the disadvantages of using capacitive sensors, the company decided to adopt strain-sensing piezoelectric elements. Specifically, they do not depend on the condition or material of the operating surface. Eventually, they found demand as switches, and the company started developing this product.

Piezo Tap™ ensures a high generated voltage even with a light tap load. During the evaluation of the developed product, it exhibited a generated voltage of approximately 1.5V with a tap load of 0.3N. When attaching it to a device, the use of thin, highly adhesive double-sided tape enables the strain of the enclosure during pressing to be efficiently transmitted to Piezo Tap™. Attaching the device to enclosures made of a variety of materials, including metal, plastic and glass is possible.

Piezo Tap™ suits applications, like home appliances such as refrigerators, washing machines and kitchen appliances; industrial equipment; wearable devices (smart glasses, smart watches, etc.); and outdoor-related products (cycle computers, etc.).

TDK exhibited the 7mmsq type Piezo Tap™ as a reference exhibit at CEATEC 2023 and began sample deployment of the developed product in the same year.

Currently, the company is developing a 5.5mmsq (approx. 0.3mm thick) product that is smaller in size while maintaining the same output voltage performance as the 7mmsq type. TDK targets to provide samples of the smaller product from May 2024 and start mass production in the first half of 2025. At the start of mass production, the company intends to consolidate the product size to 5.5mmsq, aiming to replace capacitive touch sensors and normal mechanical switches.

-25 March 2024-

This is an English translation of a Japanese article originally published in Dempa Shimbun Daily.