ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

TI to Surge 300mm Fab Grit With New U.S. Pledge

Texas Instruments (TI) and the U.S. Department of Commerce have signed a non-binding Preliminary Memorandum of Terms for up to US$1.6 billion in proposed direct funding under the CHIPS and Science Act. Accordingly, this will aim to support TI’s three 300mm wafer fabs already under construction in Texas and Utah. In addition, TI expects to receive an estimated US$6 billion to US$8 billion from the U.S. Department of Treasury’s Investment Tax Credit for qualified U.S. manufacturing investments.

Moreover, the proposed direct funding, coupled with the investment tax credit, would help TI provide a geopolitically dependable supply of analog and embedded processing semiconductors.

“The historic CHIPS Act is enabling more semiconductor manufacturing capacity in the U.S., making the semiconductor ecosystem stronger and more resilient,” said Haviv Ilan, president and CEO of Texas Instruments.

In addition, Illan said, “Our investments further strengthen our competitive advantage in manufacturing and technology as we expand our 300mm manufacturing operations in the U.S. With plans to grow our internal manufacturing to more than 95% by 2030, we’re building geopolitically dependable, 300mm capacity at scale to provide the analog and embedded processing chips our customers will need for years to come.”

Building geopolitically dependable capacity

Since its founding more than 90 years ago, TI has been advancing technology, pioneering the transition from vacuum tubes to transistors and then to integrated circuits. Presently, TI is the largest U.S. analog and embedded processing semiconductor manufacturer.

Furthermore, TI chips are essential in nearly every type of electronic device, from cars with advanced safety and intelligence systems to life-saving medical equipment and smart appliances that make homes safer and more efficient.

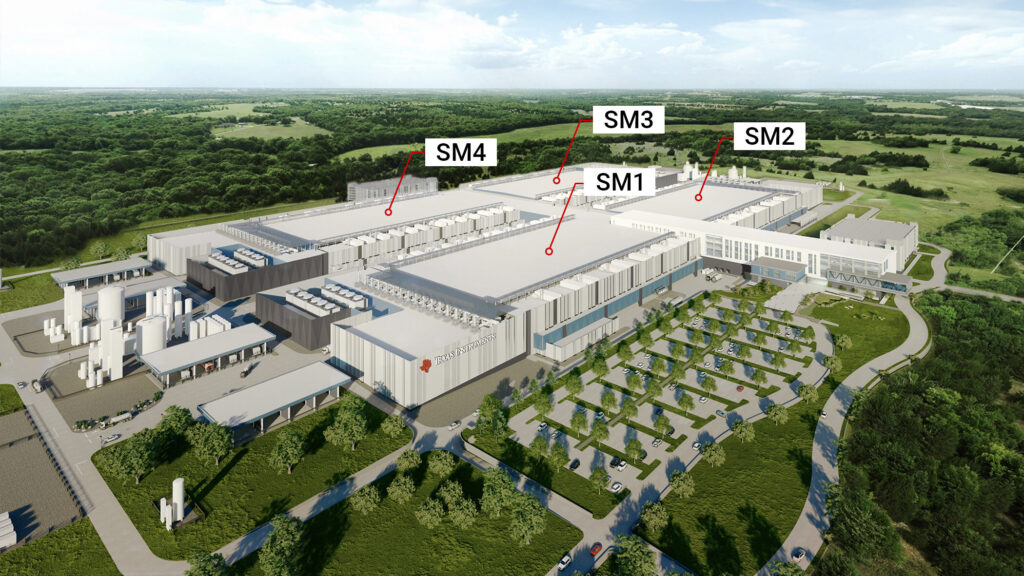

The proposed direct funding under the CHIPS Act would support TI’s investment of more than $18 billion through 2029. Specifically, this is part of the company’s broader investment in manufacturing. This proposed direct funding will support three new wafer fabs, two in Sherman, Texas, (SM1 and SM2) and one in Lehi, Utah (LFAB2). Specifically, to:

- Construct and build the SM1 cleanroom and complete pilot line for first production;

- Construct and build the LFAB2 cleanroom for first production; and

- Construct the SM2 shell.

These connected, multi-fab sites benefit from shared infrastructure, talent and technology sharing. Most importantly, it will provide a strong network of suppliers and community partners.

They will produce semiconductors in 28nm to 130nm technology nodes, which provide the optimal cost, performance, power, precision and voltage levels required for TI’s broad portfolio of analog and embedded processing products.

19 August 2024