ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

BASF to Soar 3D Tech Capacity With More Investments

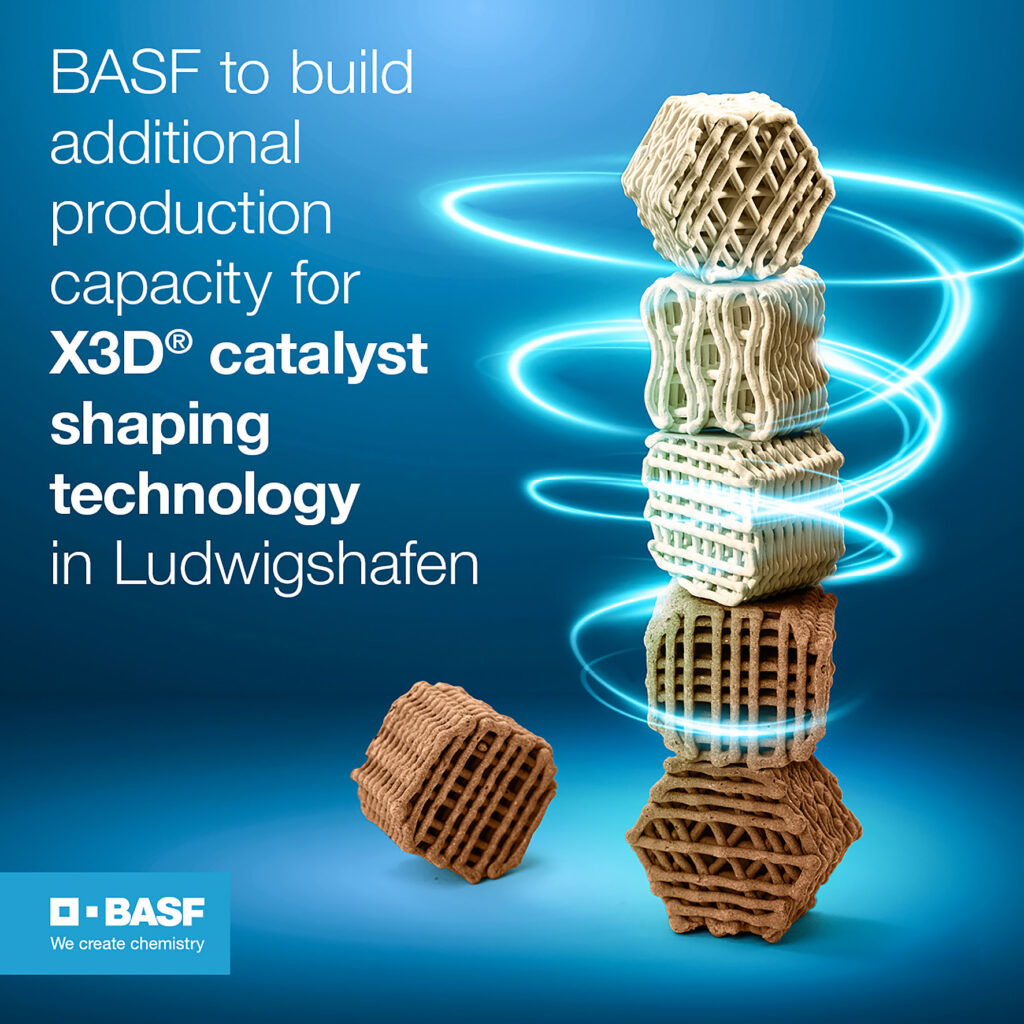

BASF has announced investing in additional production capacity for its X3D® technology. Accordingly, the tech is a new additive manufacturing technology for catalysts based on 3D printing. Most importantly, the plant will produce catalysts on an industrial scale and is expected to be operational in 2026.

The X3D technology represents a transformative leap in catalyst design and production.

Catalysts produced using this technology are not only mechanically robust but also feature an open structure. This significantly reduces pressure drop across reactors and increases surface area. These advancements translate into improved catalyst performance. Thus, helping customers to achieve greater efficiency in their plants.

They can benefit from an increased reactor output, higher product quality and a lower energy consumption, contributing to the customer’s green transformation goals.

Customize to Meet Market Needs

One of the key benefits of the X3D technology is its versatility. Its application is possible to a wide array of catalytic materials. This includes both precious and non-precious metal catalysts, as well as carriers. This flexibility allows BASF to customize catalysts according to specific customer requirements by fine-tuning parameters such as infill patterns, fiber diameters, and orientations.

“BASF remains committed to leading the charge in innovation within the chemical catalysts industry. X3D represents a step-change advancement in technology for catalyst production. We are proud to give our customers new opportunities to boost the performance of their production and at the same time reduce their carbon footprint,” said Detlef Ruff, Senior Vice President, process catalysts at BASF.

Meanwhile, Jens Perregaard, Vice President, custom catalysts & innovation said, “BASF has successfully operated commercial plants using X3D catalysts for several years. Thus, achieving remarkable results. This technology (will) shape the future for both green and traditional value chains with unparalleled efficiency and improved speed-to-market.”

Greater Design Freedom

The technology offers a greater freedom of catalyst design compared to conventional production technologies. It brings catalysts’ performance to the next level. Moreover, it helps to customize catalysts to customers’ specific conditions and needs by designing infill pattern, fiber diameter and orientation. Customers can benefit from an increased reactor output, higher product quality, and lower energy consumption. The novel catalysts are mechanically robust and proven in commercial plant operation externally and for several years in BASF.

BASF can apply the technology to a wide variety of existing catalytic materials. Among them include base or precious metal catalysts as well as carrier materials. BASF’s Sulfuric Acid catalysts O4-111 X3D and O4-115 X3D are the first catalysts produced with the new technology and are used in industrial plants.

13 November 2024