ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Technology Trends Propel 3D Printer Market

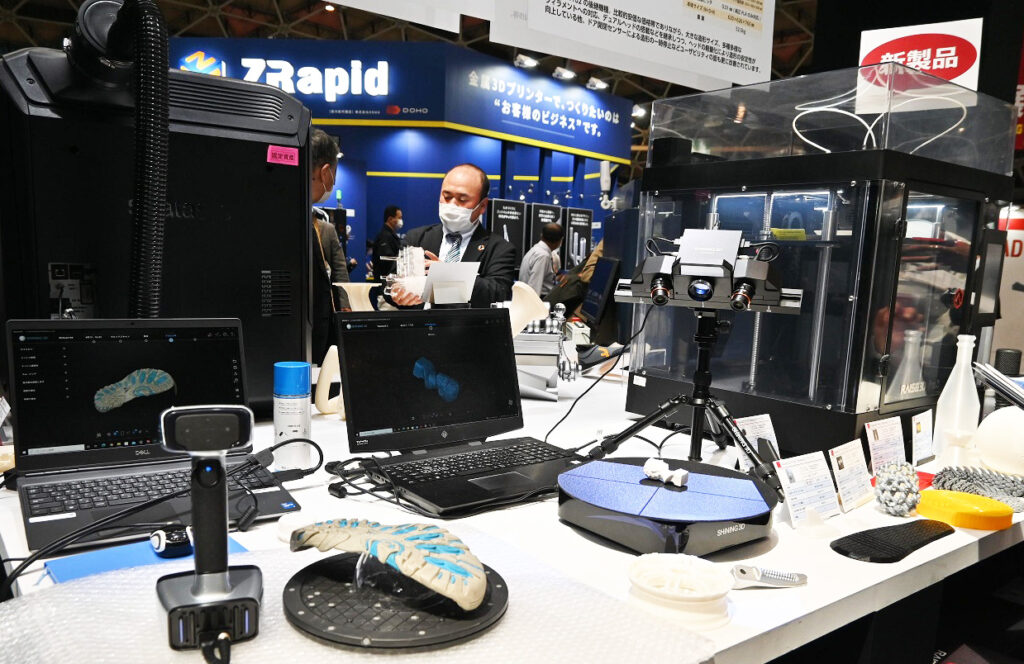

The three-dimensional (3D) printer market has been expanding into various businesses. Most importantly, the growth encompasses critical sectors such as aerospace, automobile manufacturing, molding, and medical equipment fields.

Along this trend, several sectors have been entering the market. These include new electric and electronic equipment manufacturers, including factory automation (FA) equipment and mounting-related equipment manufacturers, and industrial printing companies.

Additive Manufacturing Plays Role

3D printers create products by laying down successive layers of metal or resin. Particularly, they enable the production of prototypes directly from design data without the need to create a mold. Moreover, they also enable smaller designs and components that have been difficult to produce using the conventional processing methods.

Through additive manufacturing, 3D printers also enable the reduction of the number of components. The United States and countries in Europe have led the 3D printer technology, using them primarily to produce prototypes. Currently, however, many 3D printers developed can produce components for mass production have. Thus, expanding the range of application.

3D printers that use metal come in two types in terms of the material supply method.

They are the powder-fed method and the wire-fed method. Mitsubishi Electric Corporation entered the 3D printer market in September 2019 with the release of the EZ300 power-fed-type 3D printer. Recently, the company released the AZ600 wire-fed-type 3D printer.

In the powder-fed method, metal powder spreads on a flat surface. To laminate the metal, it is necessary melt and solidify layer by layer repeatedly. Hence, it enables the creation of high-precision 3D structures with complex shapes. Used as a heat source is a laser light with excellent controllability. There is a need to appropriately control the heat input in accordance with fabrication conditions to melt welding wire. For that reason, the creation of high-quality 3D structures.

More Players Enter Market

With 3D printers that use resin, FUJI Corporation entered the market in 2019. The company developed the FRM-Trinity with a totally new concept. The FPM-Trinity is an all-in-one equipment, which can create 3D structures, print electronic circuits, and mount components. As it does not require masks and jigs, it enables high-mix, low-volume production. In addition, it allows production of customized products easily. FUJI has started contract services to prototype electronic modules using the FRM-Trinity.

Mimaki Engineering Co., Ltd. entered the 3D printer market in 2017. In addition, it has been offering 3D printers that create 3D structures using acrylic ultraviolet (UV) curable resin. Leveraging the inkjet and UV curable ink technologies it has nurtured over many years, the company developed the 3DUJ-553 3D printer with 10 million full colors. With this as the start, the company has expanded its lineup, adding the thermal fusion lamination printers,1.8m large modeling printers, and the entry model with 10 million full colors.

The company’s full color 3D printers simultaneously perform the modeling operation of 3D object and full-color surface printing operation. Thus, enabling the creation of full-color 3D objects with high saturation.

Businesses of 3D printers’ key parts have also become active.

Hitachi High-Tech Corporation has begun to offer single-crystal electron sources for electron microscopes and other instruments. Particularly, the company is targeting the metal 3D printing markets. Its group company Applied Physics Technologies, Inc. (APTech) manufactures the electron sources.